In the modern world, a generator with an electric start feature is no longer a luxury—it’s a necessity for reliable backup power, whether for a small business or a home using a best whole-house generator system. The convenience of pushing a button or relying on an Automatic Transfer Switch (ATS) to instantly restore power is unmatched. However, this convenience hinges on a single, often-neglected component: the electric start generator battery. Ironically, a generator can have a full tank of fuel and a perfectly tuned engine, but if the starting battery is dead, the entire system is useless. Battery malfunction is, in fact, one of the most common causes of generator failure.

Therefore, understanding and mastering the maintenance of your generator’s battery is the single most important step you can take to guarantee its performance when a power outage strikes. This comprehensive, over 2000-word guide will delve deep into the anatomy of a generator battery, the critical factors that threaten its lifespan, and the precise, step-by-step procedures to ensure it remains fully charged, healthy, and ready for immediate action—every single time. The principles discussed here apply equally to large standby generators and smaller, portable home backup generators.

The Critical Role of the Electric Start Battery

The battery’s job in an electric start generator is straightforward yet vital: it provides a high surge of electrical current to the starter motor, initiating the engine’s combustion cycle. Unlike a car battery, which is constantly charged by the alternator while driving, a generator battery often sits idle for weeks or months, only being called upon briefly for periodic test runs or during an emergency.

Consequently, the generator battery is subjected to the harsh realities of disuse and self-discharge. When the moment of truth arrives—a sudden power cut—the battery must deliver its peak performance instantly. This unique duty cycle makes the generator battery maintenance regimen distinct and more critical than that of a typical vehicle battery.

Types of Batteries Used in Electric Start Generators

To implement an effective maintenance plan, you must first identify the type of battery powering your unit. The two most common types are:

1. Lead-Acid (Flooded/Wet Cell) Batteries

These are the traditional, most affordable option. They feature removable caps for adding distilled water to replenish the electrolyte lost through gassing. While reliable, they are high-maintenance and require regular checks of the fluid level and specific gravity. Their typical lifespan is 2 to 3 years.

2. AGM (Absorbed Glass Mat) Batteries

A type of Valve-Regulated Lead-Acid (VRLA) battery, AGM batteries are sealed and virtually maintenance-free (you never add water). They are more resistant to vibration, have a lower self-discharge rate, and can last slightly longer—often 3 to 4 years—making them the preferred choice for many modern, low-maintenance standby systems.

3. Lithium-Ion Batteries (Less Common)

While still rare in traditional gas or diesel generators, lithium-ion (specifically LiFePO4) batteries offer significantly longer lifecycles (5 to 7+ years), are lighter, and handle deep discharges better. While an emerging trend, their higher initial cost keeps them from being the default for most residential generators.

The Four Biggest Threats to Generator Battery Health

To extend your battery’s life, you must actively combat the four primary forces that lead to premature failure. Successfully mitigating these threats is the essence of proper battery health maintenance.

1. Threat One: Self-Discharge and Deep Discharge

All batteries lose their charge over time, even when disconnected. This is called self-discharge. For a traditional lead-acid battery, this process can render it critically discharged in a matter of months. When a battery voltage drops below a critical threshold (typically 12.4V for a 12V system), it enters a state of deep discharge.

A battery that remains deeply discharged for an extended period begins to suffer from sulfation. Lead sulfate crystals form on the plates, hardening over time. This crystalline layer acts as an insulator, reducing the battery’s ability to accept a charge and deliver power. This damage is often irreversible, marking the end of the battery’s usable life.

2. Threat Two: Parasitic Loads and Internal Drains

Standby generators, and even some portable units, have onboard electronics, such as control panels, digital displays, and monitoring systems. These components draw a small but continuous current, known as a parasitic load, which slowly drains the battery over time. While necessary for system readiness, this drain accelerates the self-discharge process, necessitating a constant charging solution.

3. Threat Three: Extreme Temperature Fluctuations

Batteries are extremely sensitive to temperature. High heat (above 77°F/25°C) accelerates the chemical degradation process, drastically shortening the battery’s lifespan. For every 10°C (18°F) above the ideal temperature, the battery’s life can be halved. Conversely, extreme cold reduces the battery’s ability to produce starting current. For instance, at 0°F (-18°C), a battery may deliver less than 40% of its rated Cold Cranking Amps (CCA), making a startup attempt extremely difficult, even if the battery is fully charged.

4. Threat Four: Corrosion and Dirty Connections

Corrosion (a flaky, white or blue-green residue) on the battery terminals acts as a resistor, impeding the flow of electricity. A corroded connection significantly raises the electrical resistance, meaning less current reaches the starter motor. It’s like trying to push a garden hose through a tiny, blocked pipe. A strong, immediate surge of current is necessary to turn the generator engine over, and corrosion will sabotage this effort.

Phase 1: Proactive Maintenance – The Monthly Checklist

Effective generator battery maintenance is not a one-time affair; it is a discipline of regular, proactive checks. We recommend implementing the following checklist at least once a month, regardless of whether the generator has been used.

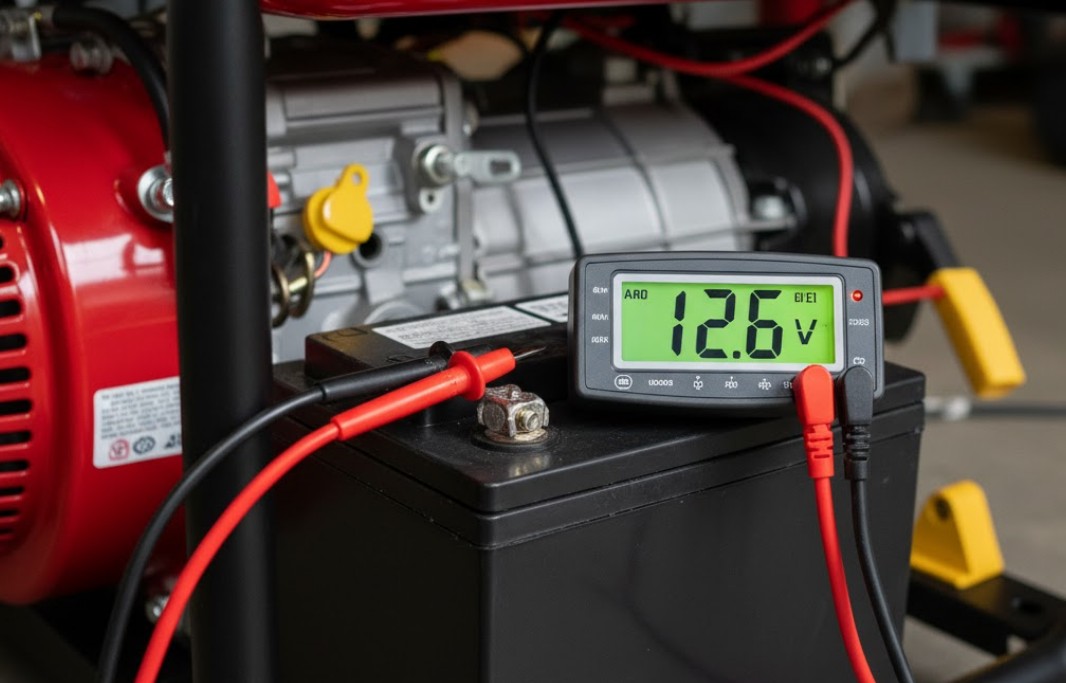

1. Voltage Check: The Health Vital Sign

A simple digital voltmeter is your most valuable tool. A fully charged 12V lead-acid battery should read 12.6 volts or higher when the generator is off. Never rely on the generator’s built-in “battery low” light, which typically only comes on when the battery is already critically low.

- Procedure: Disconnect all external charging sources. Allow the battery to rest for a few hours (known as “surface charge removal”). Place the red probe on the positive terminal and the black probe on the negative terminal.

- Interpretation:

- 12.6V +: Healthy, fully charged.

- 12.4V – 12.59V: Needs topping off (use your maintainer).

- 12.0V – 12.39V: Critically discharged; requires full recharge. Sulfation is likely occurring.

- < 12.0V: Battery is likely damaged and may not recover full capacity.

2. Physical Inspection: The Visual and Manual Scan

Visually inspect the entire battery and its cables for any sign of wear, tear, or damage. This is a quick yet crucial step.

- Check Terminals and Cables: Ensure the cable clamps are tight and securely fastened to the battery posts. A loose connection can cause intermittent starting issues, and vibration can eventually loosen the clamp further. Tug gently on each cable to confirm the tightness.

- Look for Casing Damage: Check for any cracks, leaks, or signs of swelling or bloating in the battery case. Swelling is a definitive sign of internal battery failure (often from heat or overcharging) and means the battery must be replaced immediately.

- Ventilation (Flooded Batteries Only): Ensure the vents (if present) are not blocked, allowing internal gases to escape safely.

3. Electrolyte Level Check (Flooded Batteries Only)

If you have a traditional flooded lead-acid battery, this step is mandatory. The electrolyte (a mixture of water and sulfuric acid) level drops as the battery is used and charged, especially in hot conditions.

- Procedure: Remove the vent caps. The fluid level should be above the plates inside the cells, typically up to the level indicator line (or about one inch below the cap opening).

- Replenishment: Only add distilled water to bring the level up. Tap water contains minerals that can contaminate the electrolyte and damage the battery plates. Never add sulfuric acid—the acid does not evaporate; only the water does.

Phase 2: Essential Maintenance – Cleaning and Charging

The next phase involves the hands-on work of cleaning and, most importantly, managing the charge state.

1. Cleaning the Terminals and Battery Case

As noted, corrosion is a primary saboteur. Cleaning the terminals ensures maximum current flow to the starter motor.

- Preparation: Always wear safety glasses and gloves when working with lead-acid batteries. Disconnect the negative (-) cable first, followed by the positive (+) cable.

- Cleaning Solution: Mix a solution of one cup of baking soda with one gallon of water. This neutralizes the corrosive sulfuric acid buildup.

- Procedure: Use a wire brush (a dedicated battery terminal brush is best) dipped in the baking soda solution to scrub the terminals, cable clamps, and the top of the battery case until all traces of corrosion are gone. Rinse with a small amount of clean water and dry thoroughly.

- Protection: Once reconnected (positive cable first, then negative cable), apply a thin layer of dielectric grease or anti-corrosion spray (like a battery terminal protectant spray) to the terminals and cable clamps to prevent future corrosion.

2. Maintaining the Charge State with a Smart Charger

This is arguably the single most important maintenance step. Since the battery is subject to self-discharge and parasitic loads, it must be kept at a full State of Charge (SoC) at all times. Running the generator for its monthly test run is not enough to fully recharge a discharged battery.

- The Solution: Use a dedicated automatic battery maintainer (also known as a trickle charger or float charger). This device is specifically designed to safely stay connected to the battery 24/7, keeping it at an optimal full charge (a “float” voltage, typically 13.2V) without overcharging or causing damage.

- Selection: Choose a smart charger with multi-stage charging and temperature compensation. Ensure it is compatible with your battery type (Flooded/AGM).

- Standby Generator Systems: Most modern whole-house units include an internal charging system. Ensure this system is functioning correctly by checking the battery voltage (it should read around 13.0V – 13.8V while the charger is active). If it drops when the charger is plugged in, the internal charger may be faulty.

For those using portable generators, even the best portable home backup generators, you must manually connect the maintainer between uses, especially before long-term storage, to ensure it is always ready to go.

Phase 3: Deep Maintenance and Longevity

Beyond the monthly check, there are deeper maintenance procedures and strategic decisions that will maximize the lifespan and reliability of your generator battery.

4. Load Testing: The Ultimate Stress Test

Voltage alone does not tell the full story. A battery can show 12.6V but still fail under a heavy load if its internal capacity is diminished. A load test is the only reliable way to check the battery’s ability to deliver the high current required by the starter motor.

- Procedure: Use a dedicated battery load tester or, alternatively, the generator’s starter motor itself. If the generator cranks slowly or struggles to turn the engine over, the battery is failing the “real-world” load test.

- Frequency: Perform a dedicated load test once a year or hire a professional generator technician to perform it during annual service.

5. Smart Storage and Environmental Control

If you must store your generator or battery for an extended period, follow these steps to counteract the effects of temperature and self-discharge:

- Disconnect: For long-term storage of a portable unit, disconnect the negative battery cable to eliminate all parasitic loads.

- Climate Control: If possible, store the generator or the removed battery in a cool, dry location that avoids temperature extremes (e.g., above 90°F or below freezing).

- Continuous Charging: Keep the battery connected to an automatic battery maintainer throughout the storage period to combat self-discharge and prevent sulfation.

It is worth noting that while the health of your generator battery is vital, the energy storage landscape is evolving. For comparison, the maintenance of lead-acid batteries in traditional generators differs significantly from the long-term health of solar-powered storage systems, which use different chemistries and management systems. For more insight into these alternative systems, you may find this information on how long do solar generator batteries last useful.

Knowing When to Replace Your Battery

No matter how diligent your maintenance efforts, all lead-acid batteries have a finite lifespan. Proactive replacement is always wiser than reactive replacement after a critical failure during an outage.

6. Signs of Imminent Failure:

Look for these definitive indicators that your battery is nearing the end:

- Age: The battery is nearing or has exceeded its 3-year lifespan (for flooded and most AGM batteries).

- Slow Crank: The generator starts, but the starter motor sounds noticeably slower or weaker than before.

- Voltage Sag: The battery voltage quickly drops below 12.4V after being disconnected from the charger, even after a full charge.

- Physical Damage: Any sign of swelling, warping, or leakage.

When replacing the battery, always choose one that meets or exceeds the generator manufacturer’s original specifications for CCA (Cold Cranking Amps) and capacity (Ah). Upgrading to a quality AGM battery is often recommended for better performance and reduced maintenance.

Final Thoughts

The electric start generator is a masterpiece of convenience, but its reliability is only as good as the care given to its smallest, most critical component. By committing to a consistent monthly routine of voltage checks, terminal cleaning, and—most importantly—utilizing an automatic battery maintainer, you directly combat the forces that cause 90% of generator battery failures.

Treating your generator battery as the vital component it is—a true lifeline of backup power—will ensure that when the lights go out, the simple push of the start button is met with the powerful, reliable roar of an engine ready for service. Mastering How To Maintain Battery Health In Electric Start Generators is the difference between a minor inconvenience and a major crisis.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!