In a world where reliable power is paramount, the versatile dual fuel generator has become an increasingly popular choice for homeowners, campers, and job sites alike. These ingenious machines offer the flexibility to run on two different fuel sources—typically gasoline and liquid propane (LP)—providing a crucial layer of backup and operational efficiency. The ability to switch between these fuels is a significant advantage, but it’s a process that must be understood and executed correctly for the generator to function optimally and, most importantly, safely.

This comprehensive guide will demystify the mechanics of dual fuel operation, provide a step-by-step procedure for safely and effectively switching between gasoline and propane, and share essential tips to ensure your generator remains a reliable source of power for years to come. Whether you’ve just purchased a new dual fuel inverter generator or are simply looking to master your existing unit, mastering the fuel switch is a skill every owner should possess.

Understanding the Dual Fuel Advantage

Before diving into the switching procedure, it helps to appreciate why dual fuel capability is so beneficial. This operational flexibility isn’t just a convenience; it’s a strategic advantage, especially during long power outages or unpredictable weather events.

Gasoline vs. Liquid Propane (LP)

Each fuel type brings its own set of characteristics to the generator’s performance:

- Gasoline: Generally provides a higher power output (wattage) compared to propane, which can be critical for starting high-amperage appliances. It’s also widely available at any gas station. However, gasoline has a short shelf life (often only 3-6 months without a stabilizer), and its fumes are highly flammable, requiring strict safety protocols during refueling.

- Liquid Propane (LP): Offers a cleaner burn, leading to less carbon buildup in the engine. Crucially, propane can be stored indefinitely without degradation, making it the ideal long-term backup fuel. While propane slightly reduces the maximum power output, it is safer to store and handle. It is also often readily available in common BBQ-style tanks, making it easy to stock up on.

The core advantage of a dual fuel generator is the ability to use gasoline for maximum power when you need it, and then switch to propane for extended run times and hassle-free long-term storage, knowing the fuel won’t spoil. This balance of power and longevity is what makes these units indispensable.

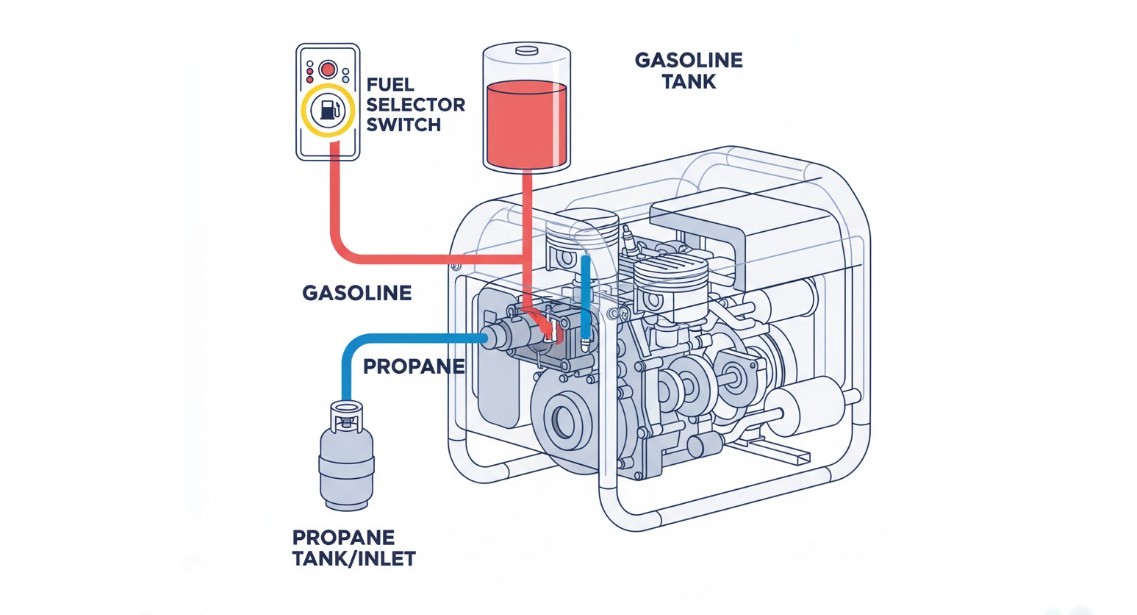

The Anatomy of the Fuel Switch System

To safely switch fuels, it’s vital to know the key components involved in your generator’s dual fuel system. While designs vary between manufacturers (e.g., Champion, Generac, DuroMax), most systems share these basic elements:

- The Fuel Selector Switch/Dial: This is the main interface. It’s a physical switch or dial on the generator’s control panel or carburetor that tells the engine’s intake system which fuel to draw from—labeled typically as “Gasoline” (or “Gas”) and “Propane” (or “LP”).

- The Propane Inlet: A brass or metal fitting on the generator’s body where the LP hose and regulator assembly connect. This must be secure and leak-free.

- The LP Regulator and Hose: Propane tanks store fuel at high pressure. The regulator is a mandatory component attached to the generator’s inlet (or sometimes the tank itself) that lowers the pressure to a level the engine can safely handle.

- The Carburetor/Fuel Intake System: Dual fuel generators use a specialized carburetor or intake manifold designed to mix the correct ratio of air and either atomized gasoline or gaseous propane vapor. The selector switch physically or mechanically alters this system’s configuration.

Step-by-Step Guide: How To Switch Between Fuels

The most important rule in switching between fuels is to never switch the fuel selector dial while the generator is under load (running appliances) or operating at full speed. This can cause the engine to stall abruptly or, worse, damage the carburetor/fuel system due to an incorrect air-to-fuel ratio during the transition.

Switching From Gasoline to Liquid Propane (LP)

The process of switching from the liquid fuel (Gasoline) to the gaseous fuel (Propane) is a key procedure that requires careful execution:

Step 1: Disconnect All Loads and Prepare for Shutdown

First and foremost, disconnect all appliances and electrical devices from the generator’s outlets. The generator must be running with no electrical load. You should also turn off the main circuit breaker if your unit is connected to a transfer switch, such as for a whole house generator setup. Allow the engine to idle for a minute or two to stabilize.

Step 2: Shut Off the Gasoline Supply

Locate the gasoline shut-off valve (often a petcock near the fuel tank or carburetor) and turn it to the OFF position. This is a critical step, as it stops the flow of gasoline to the carburetor.

Step 3: Run the Engine Dry

Keep the generator running with the gasoline valve closed. The engine will continue to run until it consumes all the remaining gasoline left in the carburetor bowl. This process, often called “running the carburetor dry” or “purging,” typically takes between 2 to 5 minutes, depending on the generator model. The engine will sputter and then shut down completely. This clears the gasoline from the system, preventing mixture issues when you introduce propane.

Step 4: Connect the Propane Tank

Once the generator has completely stopped, and the engine is cool to the touch, connect the LP hose regulator assembly to the generator’s propane inlet. Then, connect the hose to your LP tank. Ensure both connections are hand-tight and secure. Use a soapy water solution to check for leaks at all connection points; bubbles indicate a leak that must be fixed immediately.

Step 5: Select Propane on the Fuel Switch

Move the generator’s fuel selector switch or dial to the PROPANE (or LP) position.

Step 6: Open the Propane Supply

Slowly turn the valve on the top of the LP tank fully OPEN (counter-clockwise). You may hear a slight hiss as the propane enters the line and the generator’s regulator. Wait about 30 seconds for the pressure to stabilize within the system before starting.

Step 7: Start the Generator

Follow your generator’s starting procedure (pull cord or electric start). Propane often requires a few more pulls or slightly longer cranking than gasoline to start because it is a gaseous fuel. Once it starts, let it run for a few minutes to warm up before reconnecting your electrical load.

Switching From Liquid Propane (LP) to Gasoline

Switching back to gasoline is generally a more straightforward process, as you don’t need to run the system dry.

Step 1: Disconnect All Loads and Stabilize

As before, remove all electrical loads and let the generator run at no-load for a minute or two.

Step 2: Shut Off the Propane Supply

Turn the valve on the LP tank to the OFF (clockwise) position. This stops the flow of gaseous fuel.

Step 3: Wait for Engine Stalling

Allow the generator to continue running. It will use up the small amount of propane that remains in the hose and regulator system. The engine will sputter and turn off completely. This process ensures the system is cleared of propane vapor.

Step 4: Disconnect the Propane Tank

Once the engine is off, disconnect the LP hose from both the generator and the tank. Store the tank with the valve closed, and place the safety cap back on the generator’s inlet if one is provided.

Step 5: Select Gasoline on the Fuel Switch

Move the generator’s fuel selector switch or dial to the GASOLINE (or GAS) position.

Step 6: Open the Gasoline Supply

Turn the gasoline shut-off valve (petcock) to the ON or RUN position. Wait about 30 seconds for the fuel to flow and fill the carburetor bowl.

Step 7: Start the Generator

Start the generator using the standard procedure. Because the carburetor is now primed with liquid fuel, it should start quickly. Let it run for a few minutes to ensure stable operation before restoring the electrical load.

Crucial Safety Precautions When Switching Fuels

Safety is not negotiable when dealing with flammable fuels. Adhering to strict safety guidelines is essential to prevent injury, fire, or damage to your equipment.

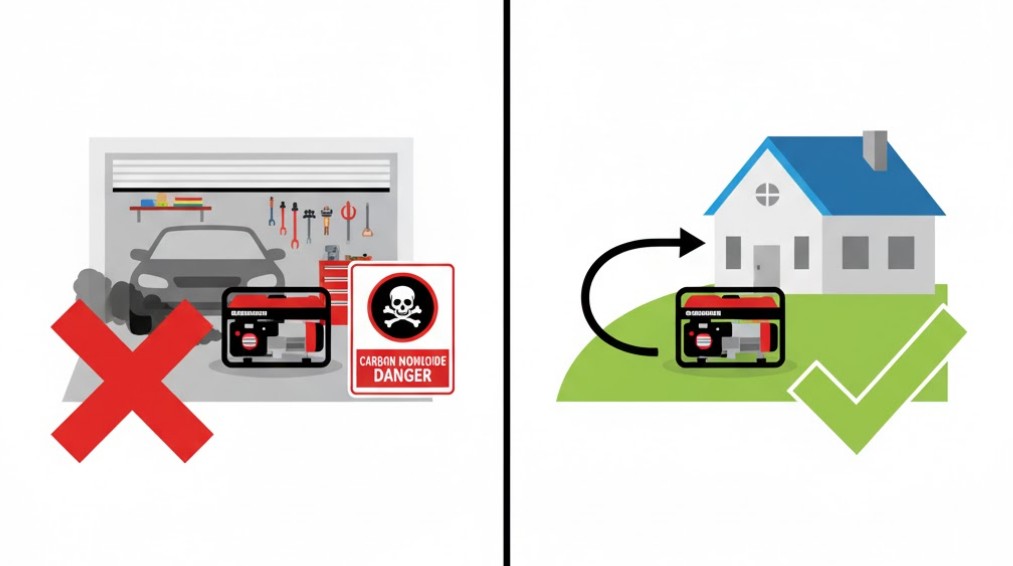

Carbon Monoxide: The Silent Killer

All generators, regardless of fuel type, produce carbon monoxide (CO), an odorless, invisible, and deadly gas. Never operate your dual fuel generator in an enclosed space, including a garage, basement, or shed. Always place the generator outdoors, away from windows, doors, and vents, with the exhaust facing away from your home. Ideally, maintain a distance of at least 20 feet (6 meters).

Handling and Storage Safety

- No Hot Refueling: Never attempt to pour gasoline into the tank while the generator is running or hot. Gasoline vapors are highly explosive. Always shut down the engine and allow it to cool completely before opening the gas cap.

- Propane Leak Check: Before connecting the LP hose for the first time or after a switch, perform a leak test by spraying a soapy water solution on all connections. If you see bubbles, you have a leak. Tighten the connection or replace the hose/regulator immediately.

- Fuel Storage: Store gasoline in approved, sealed containers and away from the generator and any heat sources. Propane tanks should be stored outdoors in an upright position.

Troubleshooting Common Switching Issues

Even when following the steps carefully, dual fuel generators can sometimes present minor challenges when switching fuel types. Here are solutions to the most common problems:

1. Generator Won’t Start on Propane

- Check for Gas in the Carburetor: Did you fully run the generator dry after switching off the gasoline valve? If not, the engine is attempting to run on a mixture of gasoline and propane, which will prevent it from starting. Repeat the “run-dry” procedure.

- Check Propane Flow: Is the LP tank valve fully open? Is the regulator correctly attached? Propane needs a small amount of time (30 seconds to a minute) after opening the valve to build up pressure in the line before the generator is started.

- Cold Weather: In very cold temperatures, the pressure in a propane tank drops, making it harder to vaporize the fuel. Warm the tank slightly (never with direct heat) or consider a larger tank size, which is less susceptible to pressure drops.

2. Generator Stalls After Switching to Propane

This is often a sign of insufficient fuel delivery. Ensure your LP regulator is working correctly and is rated for the generator’s size. Check the propane hose for any kinks or damage that could restrict flow. Sometimes, simply closing and re-opening the tank valve can reset the pressure and solve the issue.

3. Reduced Power on Propane

A slight drop in wattage is normal when running on propane compared to gasoline (typically about 10-15% less power). However, if the reduction is significant, check your tank level—propane tank pressure drops as the fuel level decreases, which can severely limit the generator’s performance.

Maintenance Tips for a Healthy Dual Fuel System

Proper maintenance ensures the generator is ready to switch fuels and run reliably whenever you need it. A dual fuel system requires attention to both components.

- Exercise Regularly: Run your generator at least once a month for 15-30 minutes, preferably alternating between both gasoline and propane. This keeps the engine lubricated, circulates fresh fuel, and confirms that both fuel systems are working correctly.

- Fuel Stabilization (Gasoline): Always use a quality fuel stabilizer if you plan to keep gasoline in the tank for more than 30 days. However, for long-term storage, it is best practice to run the gasoline dry and store the unit on propane.

- Check Hoses and Connections: Periodically inspect the LP hose and regulator for cracks, wear, or damage. Replace the propane hose every few years, as the material can degrade over time.

- Oil and Filter Changes: Follow the manufacturer’s maintenance schedule for oil changes and air filter replacements. A well-maintained engine is better equipped to handle the slight differences in performance between the two fuel sources.

Final Thoughts

The flexibility offered by dual fuel generators is an invaluable asset, providing peace of mind during unexpected power disruptions. By understanding the fundamentals of how to switch between fuels in dual fuel generators, committing to the correct procedure—especially the critical “run-dry” step when moving from gas to propane—and prioritizing safety above all else, you ensure your backup power solution is always ready for action.

Mastering this simple switch means you can confidently leverage the higher output of gasoline for heavy-duty starting and then transition to the clean, long-lasting reliability of propane for extended run times. Invest the time to practice the switch and perform routine maintenance; it’s the best way to protect your investment and secure your power supply.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!