A clean welding helmet lens isn’t just about clear vision—it’s a critical part of your personal safety and the key to a perfect weld. Learn the essential steps to properly clean and maintain your welding helmet lens for optimal performance and protection.

Think of your welding helmet lens as the window to your work—a window that, when dirty, can turn a simple task into a frustrating and dangerous one. Over time, that window becomes clouded by spatter, dust, grime, and smudges from your hands. This accumulation isn’t just a minor annoyance; it’s a serious hazard that can lead to poor weld quality, frustrating mistakes, and, most importantly, severe eye strain or injury. Many welders mistakenly believe that the occasional wipe-down is enough, but a few minutes of proper care can significantly extend the life of your helmet and ensure you always have a sharp, unobstructed view of your work.

This comprehensive guide will walk you through everything you need to know about how to clean welding helmet lens of different types of welding helmets. We’ll show you how to identify when it’s time for a deep clean, what tools you need, and provide a detailed, step-by-step process for both passive and auto-darkening lenses. We’ll also share essential tips for maintaining your lenses, troubleshooting common issues, and answer frequently asked questions to help you keep your vision crystal clear and your welding safe and efficient. Let’s get started and make sure your helmet’s lens is always in top condition.

Why a Clean Welding Helmet Lens Is Crucial

Beyond simply seeing what you’re doing, a clean welding helmet lens directly impacts several key aspects of your work and safety:

- Enhanced Safety: An obstructed view can lead to accidental arc flashes, poor positioning, and contact with hot metal or sparks, increasing the risk of injury. Clear vision allows you to precisely strike and maintain the arc, preventing these hazards. You need to keep proper welding ventilation on your workplace.

- Improved Weld Quality: Precision is everything in welding. A clear lens helps you monitor the weld pool, control bead placement, and detect defects in real-time, resulting in stronger, cleaner, and more professional-looking welds.

- Reduced Eye Strain: Straining to see through a dirty or scratched lens can cause significant eye fatigue, headaches, and long-term vision problems. A pristine lens minimizes effort, allowing for more comfortable and productive work sessions.

- Extended Lens Lifespan: Regular and proper cleaning prevents abrasive particles from scratching the lens during use, and removes corrosive elements from spatter, prolonging the life of expensive auto-darkening filters and passive lenses.

- Cost Savings: By extending the life of your lenses and preventing welding errors, proper cleaning reduces the need for frequent replacements and rework, saving you money in the long run.

When to Clean Your Welding Helmet Lens

Knowing when to clean your lens is just as important as knowing how. Here are common indicators:

- Are there visible smudges or fingerprints? If you can see fingerprints, dust, or dirt on the lens, it’s definitely time for a clean.

- Is there spatter buildup? Those tiny, rough specks of molten metal that land on your helmet can fuse to the outer lens. If not carefully removed, they can become permanent obstacles in your line of sight.

- Does your vision feel blurry or distorted? If you’re struggling to maintain focus on the weld pool, or your vision seems hazy, a dirty or scratched lens is almost certainly the cause.

- Have you been welding for a while? A quick wipe-down before every welding session can prevent major buildup, and a thorough cleaning is highly recommended after any long project.

Tools and Supplies You’ll Need

Gathering the right supplies before you start will make the cleaning process efficient and safe for your lens:

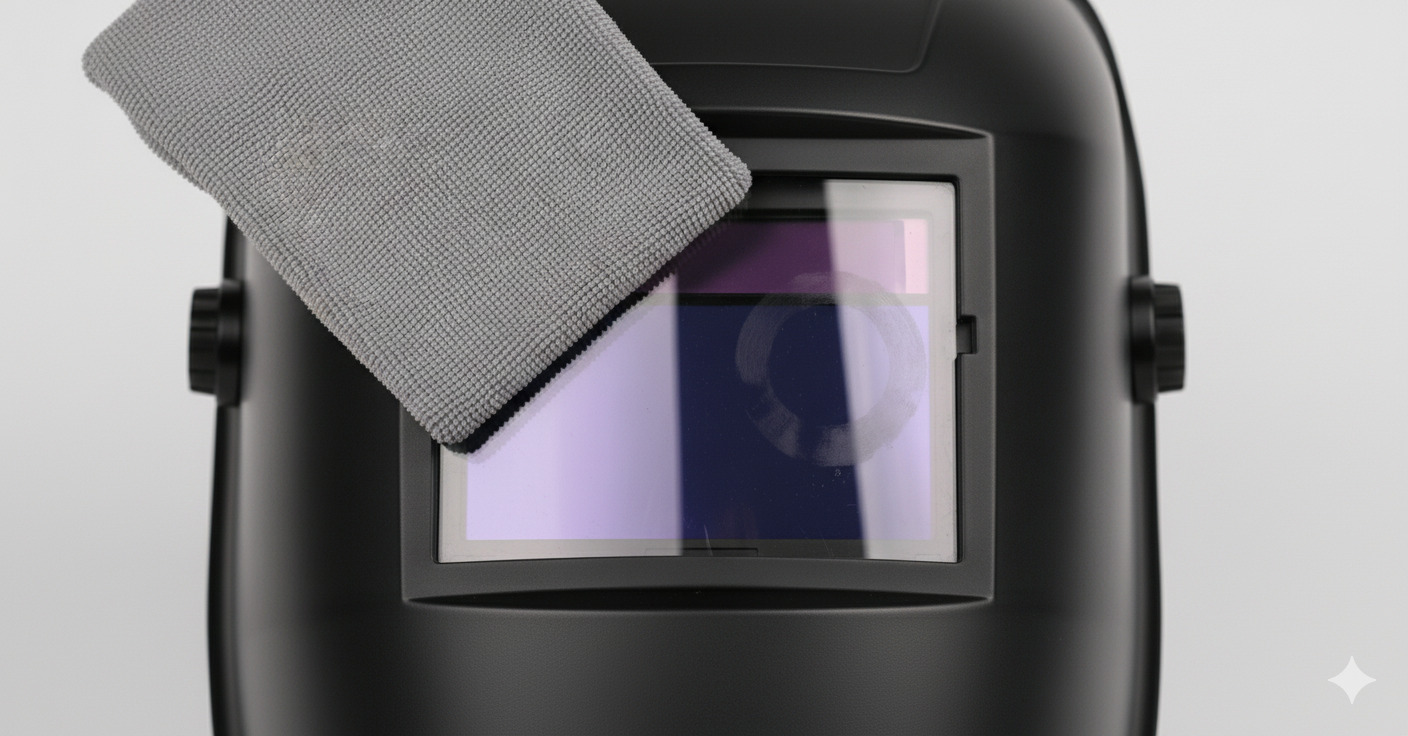

- Soft, Lint-Free Microfiber Cloths: Essential for wiping without scratching.

- Mild Soap or Lens Cleaning Solution: Avoid harsh chemicals. Specialized lens cleaners are ideal.

- Distilled Water: For rinsing and mixing with soap, to prevent mineral spots.

- Soft Brush or Compressed Air: To remove loose debris without scratching.

- Cotton Swabs or Lens Cleaning Wipes (Optional): For small areas or on-the-go cleaning.

- Replacement Outer Cover Lenses (Optional): If your current one is heavily scratched or pitted.

Step-by-Step Guide: How to Clean Your Welding Helmet Lens

The cleaning process differs slightly between passive and auto-darkening helmets because of their internal components. Always consult your helmet’s user manual for specific instructions.

Cleaning Passive Welding Helmet Lenses

Passive helmets typically have three layers: a protective outer cover lens, the fixed-shade filter lens, and an inner clear cover lens.

- Carefully Remove the Lenses: First, open the retaining clips or the frame that holds the lenses. Gently remove the outer cover lens, followed by the fixed-shade filter, and then the inner cover lens. Be sure to remember their order for reassembly.

- Remove Loose Debris: Use your soft brush or compressed air to gently remove any loose dust, metal particles, or spatter from all three lenses. This is a critical step to prevent scratching.

- Clean the Fixed-Shade Filter: This is the glass lens that provides the dark shade. Dampen a microfiber cloth with your cleaning solution and gently wipe both sides of the filter in a circular motion. Rinse thoroughly with distilled water and dry completely with a clean, dry microfiber cloth, ensuring no water spots remain.

- Clean the Cover Lenses: The clear inner and outer cover lenses are often made of polycarbonate. Use the same cleaning solution and gently wipe both sides of each lens. Rinse and dry them completely. Now is the time to inspect them: if the outer cover lens has deep scratches or pits from spatter, it’s a good idea to replace it immediately.

- Reassemble Everything: Once all three lenses are completely dry, place them back into the helmet frame in the correct order: inner cover lens first, followed by the fixed-shade filter, and then the outer cover lens. Secure them back into place.

Cleaning Auto-Darkening Welding Helmet Lenses

Auto-darkening filters (ADFs) are electronic and require extra care. They are sealed units, with replaceable clear cover lenses on the outside and inside.

- Remove the Outer Cover Lenses: Carefully remove the outer and inner clear cover lenses from the helmet. The ADF itself should remain safely inside the helmet’s frame.

- Remove Loose Debris: Use a soft brush or compressed air to gently clear any loose dust or spatter from the cover lenses and the front surface of the ADF.

- Clean the Cover Lenses: Wash the outer and inner clear cover lenses with your cleaning solution and a soft microfiber cloth. Rinse and dry them completely. This is a good time to inspect the outer cover lens, as it’s the most likely to get damaged. If you see any deep scratches or pits, replace it.

- Clean the Auto-Darkening Filter (ADF) Surface: DO NOT submerge the ADF in water or use harsh chemicals. Lightly dampen a clean microfiber cloth with a lens cleaning solution and gently wipe the surface of the ADF to remove smudges. Avoid excessive pressure. Immediately dry it with a clean, dry microfiber cloth.

- Reassemble: Make sure all components are completely dry. Reattach the inner and outer clear cover lenses securely, and you’re good to go.

Important Maintenance and Safety Tips

A clean lens is a protected lens. Follow these tips to keep your helmet in top condition.

- Always Use Cover Lenses: Never weld without both inner and outer cover lenses. They are designed to take the abuse from sparks and spatter, protecting the more expensive main filter underneath.

- Replace Damaged Cover Lenses Promptly: An outer cover lens is a consumable part. If it’s scratched or pitted, it’s time to replace it. A damaged lens can strain your eyes and make welding difficult.

- Store Your Helmet Properly: When not in use, keep your helmet in a clean, dry place, ideally in a helmet bag or box, to prevent dust and scratches.

- Avoid Harsh Chemicals: Never use abrasive cleaners, solvents, or ammonia-based products like window cleaner on any part of your welding helmet lens. They can damage anti-scratch coatings or the delicate electronics of an ADF.

- Keep a Cleaning Kit Handy: Having a dedicated lens cleaning kit in your welding area will make regular maintenance a quick and easy habit.

- Keep Out of Smoke: It’t very important to keep yourself out of smoke. Because metal fume fever can attack you if you don’t use this safety measure.

Frequently Asked Questions About Cleaning Welding Helmet Lenses

Can I use Windex or glass cleaner on my welding helmet lens?

No, you should never use Windex or similar glass cleaners, especially on auto-darkening filters and polycarbonate lenses. These products often contain ammonia or harsh chemicals that can damage anti-scratch coatings or electronic components. Stick to mild soap and water or a specialized lens cleaner.

How often should I clean my welding helmet lens?

It’s best to do a quick wipe-down of your outer cover lens before each use. A more thorough cleaning of all lenses (including the main filter and inner cover lens) should be done after every extended welding session or whenever your vision becomes noticeably obstructed.

What should I do if my outer cover lens is scratched?

If your outer cover lens is scratched or heavily pitted, you should replace it immediately. They are designed to be a sacrificial layer, and continuing to weld with a damaged one will cause eye strain and poor visibility.

Is it safe to get my auto-darkening filter wet?

No, auto-darkening filters are electronic devices and should not be submerged in water. Use a lightly dampened microfiber cloth for cleaning the surface of the ADF, and ensure it’s completely dry before reattaching the cover lenses.

Related: Top 10 Welding Helmets Reviewed

Final Thoughts

A clean welding helmet lens is a non-negotiable aspect of safe and effective welding. By following the simple steps outlined in this guide and making a habit of regular lens care, you’ll ensure that your vision remains crystal clear, your welds are precise, and your eyes are always protected. Don’t underestimate the power of a pristine view—it can dramatically improve your productivity, the quality of your work, and your overall safety in the workshop. Make lens cleaning a habit, and enjoy the benefits of clear, confident welding.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!