A generator is perhaps the most critical piece of equipment you hope you never have to use—but when the power goes out, its performance is non-negotiable. Whether it’s a whole-house standby generator protecting your family from the elements or a portable generator keeping your job site running, a generator’s ability to fire up reliably rests entirely on a consistent and detailed routine maintenance checklist. Neglecting this crucial upkeep is the single biggest reason for generator failure during an actual power outage. The cost of repair and the inconvenience of downtime far outweigh the minimal time and expense required for proactive care.

The truth is, generators are complex systems that involve an engine (gasoline, diesel, or natural gas), an alternator, a cooling system, and sophisticated electrical controls. Like any engine, parts wear out, fluids degrade, and components seize up if left idle for too long or if overworked without proper care. Therefore, adopting a tiered maintenance schedule—daily, weekly, monthly, and annually—is not optional; it is the cornerstone of reliability and longevity. This comprehensive guide provides you with a robust, actionable routine maintenance checklist for generators, breaking down the tasks by frequency and focusing on the crucial differences between generator types to ensure your machine is always in peak condition and ready to run when you need it most.

The Tiered Maintenance Schedule: Daily, Weekly, and Monthly Tasks

Preventative maintenance for any power generation unit is best organized into time-based or hour-based intervals, whichever comes first. Even if your standby generator sits idle for months, its internal monitoring systems are always active, and vital components like the battery are always on call. Regular, smaller checks prevent major failures.

Daily or Pre-Operation Checks (For Active Generators)

If your generator is running continuously during a prolonged outage or is used daily for commercial purposes, these checks are mandatory every 8–24 hours of operation.

- Visual Inspection: Walk around the unit. Look for any visible leaks—especially oil, fuel, or coolant. Check for loose connections, abnormal damage, or signs of rodent intrusion (chew marks, droppings).

- Check Fluid Levels: Use the dipstick to check the engine oil level. Ensure the oil is not discolored, which could indicate water or fuel contamination. For liquid-cooled units, verify the coolant level in the overflow tank.

- Fuel Level Check: Confirm the fuel supply is adequate for continued operation. For natural gas or propane, ensure the supply valve is fully open and the pressure is normal.

- Control Panel Status: Examine the control panel for any alarm codes, warning lights, or unusual readings (voltage, frequency, or temperature). Never ignore a warning light, as it often signals an issue that can escalate rapidly under load.

- Noise and Vibration: Listen for any abnormal noises (knocking, grinding, excessive buzzing) and feel for excessive vibration.

Weekly Exercise and Operational Readiness

The single most important weekly task for a generator that is otherwise idle (like a home standby unit) is the exercise cycle. This keeps the engine lubricated, recharges the battery, burns off moisture, and confirms readiness.

- The Exercise Run (Under Load or No-Load): Start the generator and let it run for a minimum of 15–30 minutes. Ideally, the unit should exercise under a load (e.g., in an automatic transfer switch test cycle). This is vital because running under a load prevents “wet stacking,” a condition where unburned fuel and carbon build up in the exhaust system of a diesel engine.

- Check for Leaks and Exhaust System: While running, carefully check the exhaust system (muffler, manifold, pipes) for leaks and ensure the exhaust is venting properly. Clear any debris or potential obstructions from the vents and louvers. Always maintain safe clearances; understand the importance of proper ventilation for generators.

- Check Auto Mode: For standby units, confirm that the control switch is set to the ‘Auto’ or ‘Standby’ mode after the exercise cycle, guaranteeing it will start during an outage.

Monthly: In-Depth Battery and Fluid Checks

Monthly inspections focus on components critical for starting, which are often susceptible to environmental decay.

- Battery Inspection: The battery is crucial for starting, yet it’s often the weakest link. Check the battery terminals for corrosion (a white or blue powdery buildup); clean them with a wire brush and a solution of baking soda and water. Verify the cables are tight. If the battery is not sealed, check the electrolyte level and top off with distilled water as necessary. Confirm the battery charger is functioning correctly.

- Inspect Hoses and Belts: Examine all engine hoses for cracks, swelling, or leaks. Check drive belts (alternator, fan) for proper tension and signs of fraying or excessive wear.

- Air Filter Check: Visually inspect the air filter for excessive dirt, debris, or blockages. A clogged filter severely reduces efficiency and can cause overheating. Clean or replace it if heavily soiled.

Annual and Long-Term Maintenance: The Comprehensive Overhaul

The most important maintenance tasks are performed annually or based on engine run hours (typically 100–500 hours, whichever comes first). These tasks involve replacing fluids and filters that degrade over time, ensuring the long-term health of the engine.

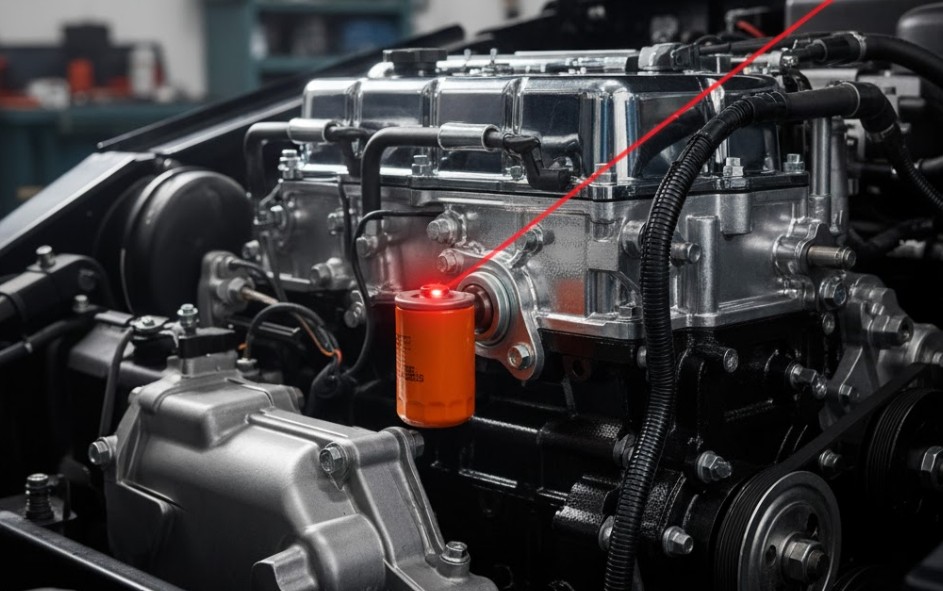

Oil and Filter Replacement: The Lifeblood of the Engine

The single most important task for generator longevity is timely oil and filter changes.

- Engine Oil Change: Change the oil and the oil filter annually or at the manufacturer’s recommended hour interval (e.g., every 100-200 hours for portable gas; 200-500 hours for standby diesel/gas). Used oil contains contaminants and acids that can damage internal components. Always use the oil weight recommended by the manufacturer, especially considering seasonal temperature changes.

- Fuel Filter Replacement: Replace the fuel filter annually. This is critical because filters remove contaminants and water. Clogged filters restrict fuel flow, leading to poor performance or engine failure. For diesel units, this often includes draining the water/sediment separator.

Fuel System Management: A Critical Difference

Different fuel types present different long-term maintenance challenges:

- Gasoline Generators: Gasoline degrades rapidly (as quickly as 30 days), forming varnish and gum that clogs carburetors. For units used infrequently, either drain the fuel completely for storage or use a high-quality fuel stabilizer and run the engine for 10 minutes to circulate the treated fuel.

- Diesel Generators: Diesel fuel can suffer from microbial growth (algae) and condensation, which introduces water into the fuel. Regular fuel quality testing and the use of biocides and fuel conditioners are essential. Periodically checking the tank for sediment and water is also a must. Fuel quality is crucial; learn more about why keeping your fuel tank clean is vital for diesel engines.

- Natural Gas/Propane: These fuels do not degrade, eliminating the biggest problem of gasoline and diesel units. Maintenance focuses more on the integrity of the fuel lines and ensuring no leaks are present.

Cooling and Electrical Systems Deep Dive

These systems require a more detailed annual inspection, often best performed by a certified technician.

- Cooling System Flush: For liquid-cooled units, the coolant mixture needs to be checked (and flushed/replaced every 2-4 years). The coolant protects against freezing (which can crack the block), but also provides corrosion resistance. Inspect the radiator fins and clean off any accumulated dirt or debris to ensure efficient heat exchange.

- Spark Plugs: For gasoline and some natural gas units, replace the spark plugs annually or bi-annually. Worn plugs cause misfires, reduce efficiency, and make starting difficult.

- Alternator and Electrical Check: A technician will inspect the alternator (the generating part of the unit), voltage regulator, and all control circuits. This includes checking the winding resistance and insulation to detect potential electrical failures before they result in a complete unit shutdown.

Advanced Testing and System Integrity Checks

Beyond the basics, true reliability is proven through testing that simulates real-world conditions.

Load Bank Testing: The Ultimate Reliability Test

Running a generator with a minimal or no load (a ‘no-load’ exercise) will not reveal all potential problems. Load bank testing involves connecting the generator to an external device that draws its rated load capacity. This forces the engine to work, heating the components and checking that the alternator can maintain stable voltage and frequency under stress. This test is highly recommended annually, especially for diesel generators and mission-critical applications, as it prevents wet stacking and verifies the unit is capable of handling its maximum load.

Transfer Switch and Safety Functions

For standby units, the Automatic Transfer Switch (ATS) is what makes the system ‘automatic.’ During the annual check, a technician should:

- Verify the ATS successfully switches power back and forth between utility and generator.

- Inspect the electrical contacts for wear or pitting.

- Test the emergency stop functions and all safety interlocks to ensure the unit shuts down correctly if a fault is detected.

Proper Placement and Environmental Factors

Maintenance extends to the environment around the generator. Ensure the generator’s pad or mounting is stable and level. Clear the area of tall grass, debris, or snow that could block the cooling vents or exhaust system. For portable generators, ensure the storage area is dry and protected from pests. Protecting your machine starts with its setup; review best practices for generator placement to maintain safety and efficiency.

Understanding Maintenance by Generator Type

While the checklist items are similar, the frequency and specific concerns vary significantly based on the fuel and design.

Portable Generator Maintenance: Flexibility and Fuel Issues

Portable generators are typically gas-powered and air-cooled, meaning they often require more frequent maintenance when they are used, but their primary challenge is dealing with fuel degradation during long periods of storage. Oil should be changed every 100-200 run hours, and spark plugs and air filters often every 200 hours. Always prioritize the fuel management steps (draining or stabilization) when putting the unit away for more than a few weeks.

Standby Generator Maintenance: Durability and Complexity

Standby generators (especially diesel and natural gas) are built for heavy-duty use. Diesel engines, in particular, run at lower RPMs and have a much longer lifespan but require intense focus on fuel quality and coolant health. Their maintenance schedule is often more time-based (annual or semi-annual technician visits) due to the complexity of the cooling systems and transfer switch, which the average user should not attempt to service.

The Logbook: Your Most Important Tool

Finally, the entire maintenance program hinges on documentation. Keep a detailed maintenance logbook. Record the date, the generator’s hour meter reading, the work performed (e.g., “Oil Change: 5W-30 Synthetic”), and any findings (e.g., “Battery voltage low; cleaned terminals”). This log serves as a warranty record, helps track wear, and is invaluable for any technician called in for service. Consistency in recording is as important as consistency in maintenance.

Final Thoughts

The routine maintenance checklist for generators is more than just a set of chores; it is an insurance policy. A well-maintained generator not only guarantees power when you need it but also operates more efficiently, safely, and extends the lifespan of your expensive investment, often by many years. By adhering to a rigorous schedule—checking the fluids and run status weekly, caring for the battery monthly, and performing comprehensive fluid and filter changes annually—you eliminate the most common causes of generator failure. Do not wait for a storm to discover your generator is failing; make prevention a habit. Your readiness depends on it.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!