Welding, a fundamental process in fabrication and construction, relies on a crucial component to create strong, durable bonds between metal pieces: the welding electrode. Also known as a welding rod, this consumable or non-consumable material plays a pivotal role in determining the quality, strength, and integrity of a weld. Understanding the different types of welding electrodes, their properties, and how to select the right one for a specific application is essential for both novice and experienced welders.

This comprehensive guide will delve into everything you need to know about welding electrodes, from their basic function and classification to practical tips on selection and best practices for their use. We’ll explore the science behind these seemingly simple rods and uncover how they are the key to achieving a perfect weld.

What is a Welding Electrode?

At its core, a welding electrode is an electrical conductor used to transfer current from a welding machine to the workpiece. During the welding process, the electrical arc generated between the electrode and the base metal melts both the electrode and the joint, creating a molten pool. As this pool cools and solidifies, it forms a permanent metallurgical bond.

Welding electrodes can be broadly categorized into two main types: consumable and non-consumable.

- Consumable Electrodes: These are the most common type and are designed to melt and become part of the weld joint. The coating on a consumable electrode, known as flux, serves multiple purposes. It creates a protective gas shield around the weld pool to prevent contamination from the atmosphere, and it also adds deoxidizing elements and alloys to improve the weld’s mechanical properties.

- Non-Consumable Electrodes: As the name suggests, these electrodes do not melt and are typically made from materials with very high melting points, such as tungsten. They are used in processes like Gas Tungsten Arc Welding (GTAW), where a separate filler metal is fed into the weld pool. The non-consumable electrode’s primary function is to maintain the arc.

The choice between a consumable and non-consumable electrode depends entirely on the specific welding process being used.

The Anatomy of a Consumable Welding Electrode

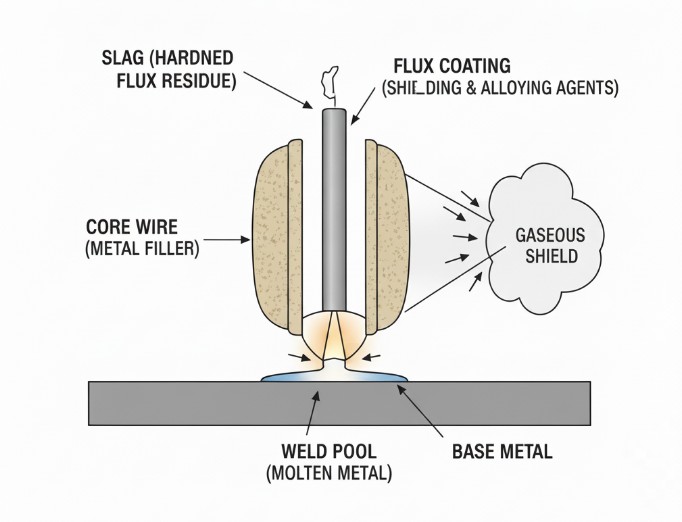

To truly appreciate the function of a welding electrode, it’s helpful to understand its components. A typical shielded metal arc welding (SMAW) electrode consists of two main parts:

- The Core Wire: This is the metal conductor at the center of the electrode. It carries the current and, as it melts, provides the filler metal for the weld. The composition of the core wire is critical as it must be compatible with the base metals being joined.

- The Flux Coating: This is the outer layer of the electrode and is arguably the most important part. The flux performs several vital functions:

- Arc Stabilization: It helps to create and maintain a stable arc, which is crucial for a smooth and consistent weld.

- Shielding: As the flux melts, it produces a shielding gas that protects the molten weld pool from oxygen, nitrogen, and other atmospheric contaminants that could embrittle the weld.

- Slag Formation: The molten flux forms a protective layer of slag over the solidifying weld. This slag helps control the cooling rate of the weld metal and protects it from rapid oxidation. Once the weld has cooled, the slag can be easily chipped away.

- Alloying: The flux can contain alloying elements that transfer into the weld metal, enhancing its strength, toughness, and other mechanical properties.

The composition of the flux coating is what differentiates one type of electrode from another and is the primary reason why certain electrodes are suited for specific applications.

Welding Electrode Classification: Understanding the Code

The American Welding Society (AWS) has established a standardized classification system for welding electrodes. This system provides a simple yet comprehensive way to identify an electrode’s properties and intended use. While there are different classifications for various types of welding processes, the most common system is for SMAW electrodes, which uses a four or five-digit number preceded by the letter “E”.

Let’s break down the meaning of a common electrode classification, such as E6010 or E7018.

- E: This stands for Electrode, indicating that it’s a welding electrode for arc welding.

- First Two Digits (e.g., 60 or 70): These numbers indicate the minimum tensile strength of the deposited weld metal in thousands of pounds per square inch (PSI). So, E60 means the weld has a minimum tensile strength of 60,000 PSI, while E70 means 70,000 PSI.

- Third Digit (e.g., 1): This number represents the welding position the electrode can be used in.

- 1: All positions (flat, horizontal, vertical, and overhead).

- 2: Flat and horizontal positions only.

- 4: Flat, horizontal, overhead, and vertical down.

- Fourth Digit (e.g., 0 or 8): This digit specifies the type of flux coating, the current type (AC/DC), and the polarity that can be used. This is a critical indicator of the electrode’s performance and characteristics.

For a more in-depth look at this classification system, you can refer to the AWS standards. Understanding this system is the first step in selecting the right welding electrode for your project.

Common Welding Electrode Types and Their Applications

Now that we understand the classification system, let’s look at some of the most popular welding electrode types and their typical uses.

- E6010: This is a classic welding electrode known for its deep penetration and fast-freezing slag. It’s often used for root passes on pipes and is a favorite among pipeline welders. It requires a direct current, reverse polarity (DCEP) machine. Because of its strong arc and deep penetration, it’s ideal for dirty or rusty metal.

- E6011: Similar to E6010 but with a modified flux coating that allows it to be used with both AC and DC welders. This versatility makes it a popular choice for home and farm applications where AC welding machines are common. It also offers a forceful arc for deep penetration.

- E6013: A versatile, general-purpose electrode with a smooth, stable arc and minimal spatter. It provides a nice, cosmetic bead and is a great choice for sheet metal and thin materials. It can be used with both AC and DC, and is often preferred by beginners due to its ease of use.

- E7018: Often referred to as “low hydrogen” electrodes, E7018 is the workhorse of industrial and structural welding. It provides exceptional tensile strength, ductility, and resistance to cracking. The low hydrogen content of the flux prevents hydrogen-induced cracking in the weld. It’s used for welding high-strength steels and is effective in all positions. E7018 is the go-to choice for critical applications where weld quality is paramount.

- E7024: This electrode is designed for high-deposition welding in the flat and horizontal positions. It’s known for its high deposition rate, which allows for fast welding of thick materials. It produces a very smooth, aesthetically pleasing bead and is a good choice for projects where speed and a clean finish are desired.

To find out more about what welding rod might be right for your specific needs, you can explore detailed reviews on various welding rod types, such as the best all-around welding rods. This can help you make an informed decision for your specific project.

Welding Electrode Selection: A Critical Decision

Choosing the correct welding electrode is not a trivial matter. An incorrect choice can lead to a weak, brittle, or cracked weld, which can have serious safety and structural consequences. When selecting a welding electrode, several factors must be considered.

1. Base Metal Type

The most important factor is the type of base metal you are welding. The electrode’s core wire and flux composition must be compatible with the base metals to create a strong, durable metallurgical bond. For example, mild steel welding typically uses E6010, E6011, E6013, or E7018 electrodes. For specialty metals like stainless steel or cast iron, you will need specialized electrodes designed for those specific alloys. Using the wrong electrode can result in a brittle weld that is prone to cracking.

2. Welding Position

As we learned from the AWS classification, some electrodes are restricted to certain welding positions. For example, E7024 is excellent for flat and horizontal welding but is not suitable for vertical or overhead applications. If you need to perform an all-position weld, you must choose an electrode with a “1” in the third digit of its classification, such as E7018 or E6010.

3. Welding Machine and Current Type

The type of current your welding machine produces (AC, DC, or both) will limit your electrode options. For instance, E6010 requires a DC machine, while E6011 and E6013 are flexible and can be used with both AC and DC. Always check the electrode’s specifications to ensure it is compatible with your equipment.

4. Required Weld Properties

Consider the final application of the welded product. Does it need to withstand high stress, low temperatures, or extreme vibration? For critical applications, low-hydrogen electrodes like E7018 are often the best choice because they produce high-strength, crack-resistant welds. For non-critical joints or general fabrication, a general-purpose electrode like E6013 might be sufficient.

5. Joint Design and Material Thickness

The thickness of the metal you are welding and the type of joint (e.g., butt joint, lap joint, tee joint) also influence electrode selection. For thicker materials, you may need an electrode with a high deposition rate to fill the joint efficiently, such as E7024. For thin materials, an electrode that provides a stable, low-amperage arc, like E6013, is often a better choice to prevent burn-through.

Best Practices for Storing and Handling Welding Electrodes

Proper storage and handling are crucial for maintaining the quality and performance of welding electrodes. Moisture is the enemy of most electrodes, especially low-hydrogen types like E7018. When the flux absorbs moisture, it can introduce hydrogen into the weld, leading to porosity and cracking.

- Store in a Dry Environment: Always store welding electrodes in a cool, dry place. For low-hydrogen electrodes, a sealed, heated cabinet or oven is often required to keep them dry and ready for use.

- Keep Packaging Intact: Do not open the packaging until you are ready to use the electrodes. The hermetically sealed packaging is designed to protect the rods from moisture.

- Re-Baking: If low-hydrogen electrodes have been exposed to the atmosphere for an extended period, they may need to be “re-baked” in a specialized oven to drive out any absorbed moisture. Always follow the manufacturer’s recommendations for re-baking temperature and time.

- Handle with Care: The flux coating on electrodes is brittle and can be damaged by rough handling. Dropping or bending the electrode can cause the flux to flake off, which will lead to an unstable arc and a poor-quality weld.

By following these best practices, you can ensure that your welding electrodes perform as intended and produce high-quality, reliable welds.

The Role of Electrodes in Different Welding Processes

While we’ve focused heavily on shielded metal arc welding (SMAW), it’s important to remember that electrodes are used in other welding processes as well.

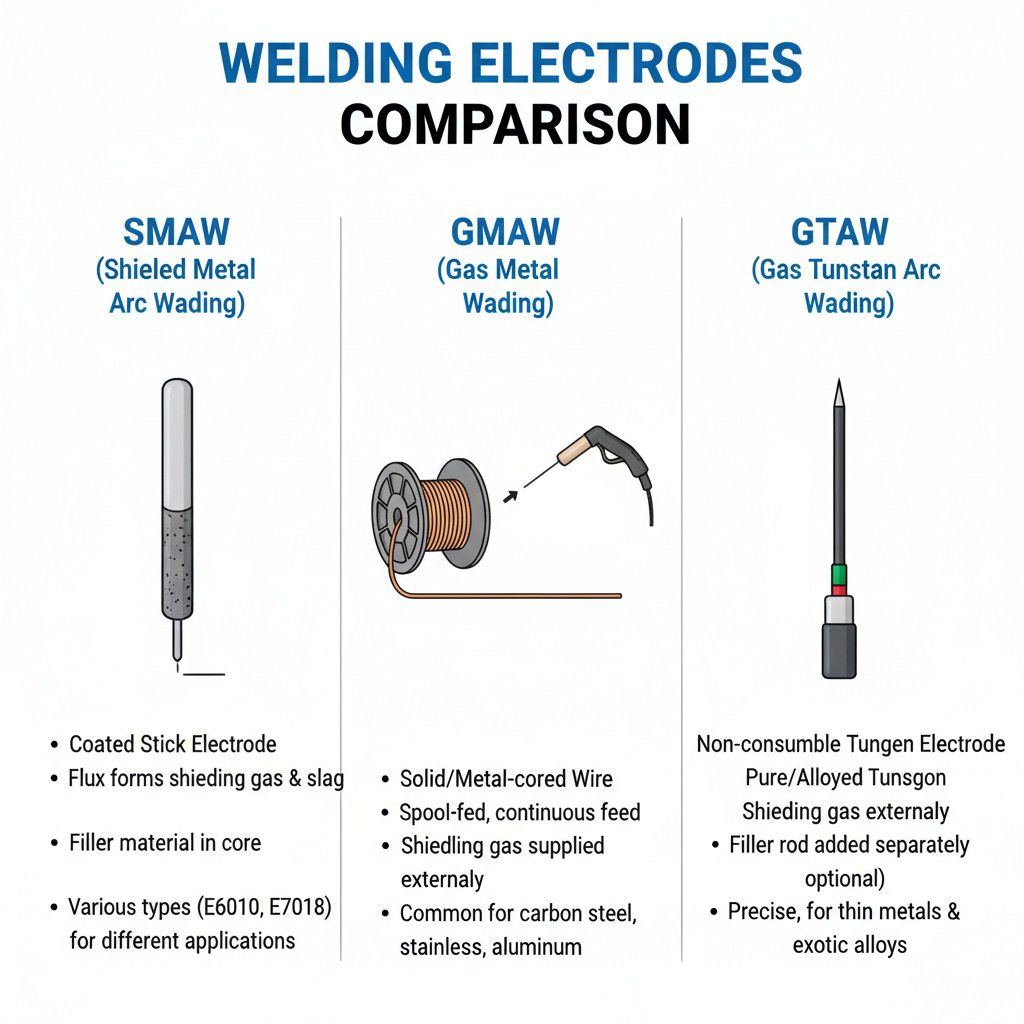

Gas Metal Arc Welding (GMAW) – MIG

In MIG welding, the electrode is a continuous wire spooled on a reel. This wire is fed automatically through the welding gun. The wire serves as the filler metal and the electrical conductor. The shielding is provided by an external gas (e.g., argon, CO2, or a mixture) that is fed through the same gun.

- Solid Wire: The most common type of MIG electrode. It is a solid metal wire that melts and becomes part of the weld.

- Flux-Cored Wire: This wire has a hollow core filled with flux, similar to an SMAW electrode. It can be used without an external shielding gas (FCAW-S) or with one (FCAW-G).

Gas Tungsten Arc Welding (GTAW) – TIG

TIG welding uses a non-consumable electrode made of tungsten. Tungsten has an extremely high melting point, allowing it to maintain the arc without melting. A separate filler rod, compatible with the base metal, is fed into the weld pool by hand.

- Pure Tungsten: The original electrode type, suitable for AC welding of aluminum.

- Thoriated Tungsten: Contains thorium oxide, which improves arc stability and current-carrying capacity. It’s often used for DC welding of steel and other materials.

- Lanthanated Tungsten: An excellent all-around electrode for both AC and DC applications. It’s becoming a popular replacement for thoriated tungsten due to its non-radioactive properties.

Understanding these different welding processes and their respective electrode types is key to choosing the right tool for the job. Additionally, consider how you’ll move your equipment; using a welding cart can greatly improve efficiency and organization.

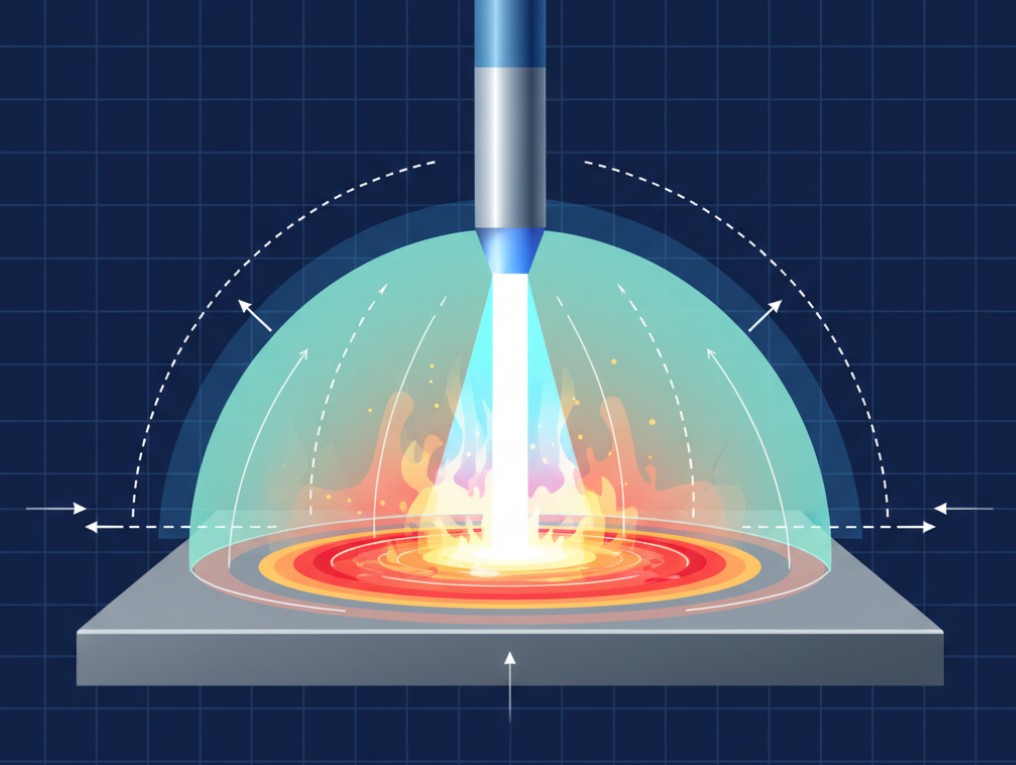

The Science of the Arc: How the Electrode Works

The magic of welding happens in the arc, which is a powerful electrical discharge that generates intense heat. The welding electrode is the tool that makes this possible. When the electrode tip touches the workpiece and is then slightly pulled away, it creates a short circuit. This causes a massive current to flow, vaporizing a small amount of the electrode tip and the workpiece, creating an ionized gas path known as the arc.

The intense heat from the arc (which can reach over 6,000∘C or 10,800∘F) melts the electrode’s core wire and the flux coating. The molten metal droplets are then propelled across the arc gap and into the molten weld pool. The gases produced by the melting flux create a protective atmosphere around the weld, preventing it from reacting with the air.

This process is a fascinating interplay of electrical, thermal, and chemical reactions, all orchestrated by the carefully designed welding electrode. To learn more about the science and history of this process, you can explore detailed resources like the Wikipedia article on electrodes.

Welding Electrodes: Chart of Common Types

| Electrode Type | AWS Classification | Current Type | Best For | Key Features |

|---|---|---|---|---|

| Mild Steel | E6010 | DC+ (DCEP) | Pipe root passes, thick materials, dirty metal | Deep penetration, fast-freezing slag, forceful arc. |

| Mild Steel | E6011 | AC, DC+ (DCEP) | All-position welding, general repair, galvanized steel | Versatile, forceful arc, good for dirty or painted surfaces. |

| Mild Steel | E6013 | AC, DC+ (DCEP), DC- (DCEN) | Thin materials, sheet metal, cosmetic welds | Smooth arc, low spatter, easy to use for beginners. |

| Mild Steel / Low Alloy Steel | E7018 | AC, DC+ (DCEP) | Critical welds, structural steel, high-strength applications | Low hydrogen, high tensile strength, excellent ductility, very strong. |

| High Deposition | E7024 | AC, DC+ (DCEP), DC- (DCEN) | Flat and horizontal welding, thick plate, high deposition rate | Very fast, smooth bead, high efficiency, heavy slag. |

| Stainless Steel | E308L-16 | AC, DC+ (DCEP) | Stainless steel alloys, corrosion resistance | Resists rust and corrosion, requires careful handling. |

| Cast Iron | ENi-CI | AC, DC+ (DCEP), DC- (DCEN) | Repairing cast iron parts, joining dissimilar metals | High nickel content, helps prevent cracking in brittle cast iron. |

*This chart provides a general overview. Always consult the manufacturer’s data sheet for specific applications.

Expanding Your Expertise: New Horizons in Welding Electrodes

Beyond the fundamental selection process, a true understanding of welding electrodes involves delving into more advanced topics. Mastery of the craft comes not just from knowing what an electrode does, but from understanding how it interacts with the environment, with safety protocols, and with the potential for things to go wrong.

Safety First: The Connection Between Safety and Welding Electrodes

While often seen as a separate topic, welding safety is intrinsically linked to the proper selection and use of welding electrodes. The fumes produced during the welding process are a significant health concern, and their composition can vary dramatically depending on the electrode type. For example, some specialized stainless steel electrodes contain chromium and nickel, which can produce highly toxic fumes when heated.

Therefore, selecting the right electrode also means selecting the right safety measures. For any welding, regardless of the electrode, adequate ventilation is a non-negotiable requirement. This could mean working outdoors, using a fume extractor, or ensuring excellent shop ventilation. Furthermore, personal protective equipment (PPE) like a proper welding helmet, gloves, and protective clothing is essential. The high intensity of the arc, even with a basic electrode like E6013, can cause severe and permanent damage to your eyes and skin without proper protection.

In short, a knowledgeable welder knows that the most effective and safest weld starts with choosing the right rod for the job and preparing the workspace accordingly. The properties of the welding electrode dictate not only the quality of the weld but also the necessary precautions to keep you safe.

Common Welding Defects and How Electrodes Can Cause Them

Even with the right technique, a weld can still be plagued by defects. Many of these issues are a direct result of improper electrode selection or handling. Understanding the root cause of these defects can help you troubleshoot and improve your welding skills.

One of the most common issues is porosity, which manifests as small holes or voids in the weld. Porosity is typically caused by trapped gases within the molten weld metal. A major contributor to this is moisture in the electrode’s flux coating. When the flux is damp, the moisture turns into steam in the arc, and the hydrogen can become trapped in the weld. This is why proper storage of low-hydrogen electrodes like E7018 is so critical. Similarly, insufficient shielding gas in MIG welding, often due to a faulty setup or improper gas flow rate, can also lead to porosity.

Another prevalent defect is undercut, which is a groove melted into the base metal along the toe of the weld. While technique plays a role, the wrong electrode can exacerbate this issue. Using an electrode with too much penetrating power or a too-long arc can lead to undercut. Conversely, an electrode with a smooth, fluid puddle like E6013 is less likely to cause this issue. By adjusting your electrode choice and arc length, you can significantly reduce the risk of undercut.

Finally, there’s slag inclusion, where bits of flux-turned-slag get trapped within the weld metal. This happens when the slag doesn’t have time to float to the surface of the weld pool. This is particularly important when doing multi-pass welds with a heavily slagging electrode.

By learning how your electrode choice and condition directly influence these defects, you gain a new level of control over your final product. A skilled welder doesn’t just fix a defect; they identify the cause, often starting with the welding electrode, and prevent it from happening again.

Specialized and Advanced Electrodes for Unique Applications

While mild steel welding rods are the most common, the world of welding electrodes extends far beyond them. For specific projects involving different materials, you need a specialized tool for the job. These advanced electrodes are engineered with unique compositions to address the metallurgical properties of different alloys.

For example, when welding stainless steel, which is prized for its corrosion resistance, you must use an electrode designed for it. These electrodes, like the E308L-16 mentioned in our chart, contain chromium and nickel to match the base metal. The “L” in the classification stands for low carbon, which helps prevent a phenomenon known as carbide precipitation that can reduce the corrosion resistance of the weld joint. Using a standard mild steel electrode on stainless steel would not only fail to create a strong joint but would also compromise the very property that makes stainless steel valuable.

Similarly, welding cast iron requires a specialized approach due to its high carbon content and brittle nature. Cast iron electrodes, such as the ENi-CI (where “Ni” stands for Nickel), are designed to produce a soft, ductile weld that can absorb the stresses of the cooling process. This prevents the cracking that would almost certainly occur if a brittle mild steel electrode were used. The high nickel content in these rods allows them to match the different expansion and contraction rates of the cast iron, making a successful repair possible.

Understanding these specialized applications and the corresponding welding electrodes is a mark of a truly knowledgeable welder. It opens up a whole new world of repair, fabrication, and artistic creation, from fixing a cracked engine block to fabricating a piece of stainless steel sculpture. The right electrode is not just about joining metal; it’s about preserving the integrity and properties of the final product.

Final Thoughts

Welding electrodes are more than just simple metal rods; they are a sophisticated component of the welding process. Proper selection, storage, and handling are crucial for achieving strong, reliable, and aesthetically pleasing welds. By understanding the welding electrode classification system, the different types available, and their specific applications, you can elevate your welding skills and confidence. The right choice makes all the difference.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!