Welding is a fundamental process in a wide array of industries, from heavy manufacturing and construction to automotive repair and artistic fabrication. While it is a critical skill, it comes with a significant occupational hazard: the generation of hazardous fumes, gases, and particulates. These byproducts pose serious health risks to welders and those in the immediate vicinity. The implementation of proper welding ventilation is not merely a suggestion—it is a mandatory safety measure regulated by bodies such as the Occupational Safety and Health Administration (OSHA) and is absolutely essential for creating a safe and healthy work environment. This article will provide an in-depth look into the dangers associated with welding fumes, the various types of ventilation systems available, best practices for their use, and the importance of regulatory compliance.

The Invisible Threat: Understanding Welding Fumes and Gases

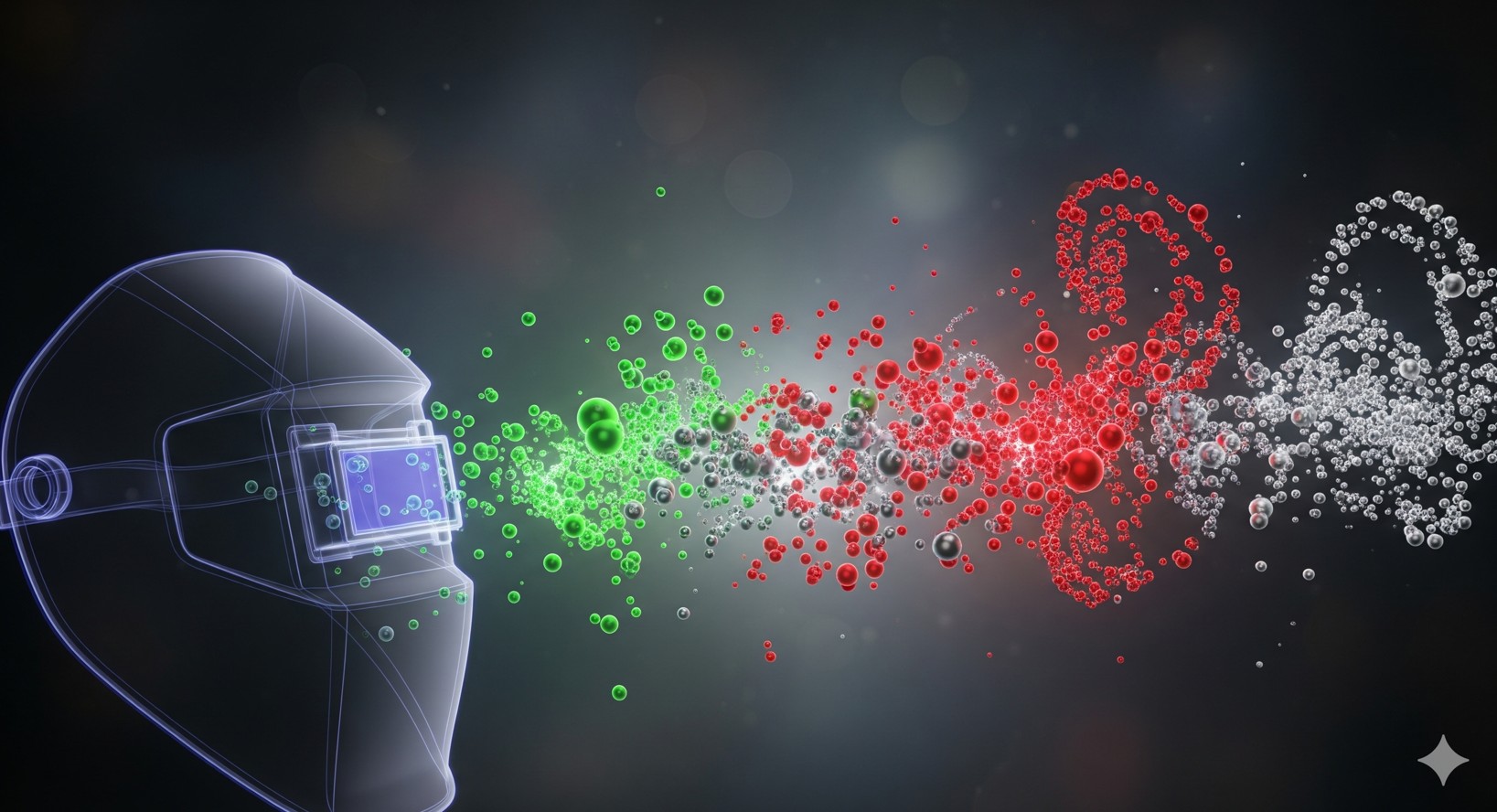

The fumes produced during welding are a complex and toxic mixture of fine particles and gases. Their composition and concentration depend heavily on the specific welding process, the base metal being welded, the filler material, and any surface coatings present. The primary dangers can be categorized into two groups: particulate matter and hazardous gases.

Particulate Matter: A Microscopic Menace

Welding particulate matter, often referred to as “fumes,” is composed of extremely small metal oxide particles. Common components include iron oxide, manganese, chromium, nickel, and zinc oxide. The health effects of inhaling these particles can be both immediate and long-term. Short-term exposure can lead to a condition known as “metal fume fever,” which presents with flu-like symptoms such as fever, chills, and muscle aches. The long-term consequences are far more severe. Chronic inhalation of certain metal particles, particularly chromium and nickel, has been definitively linked to an increased risk of lung cancer. Other long-term health issues can include nervous system damage from manganese exposure, and a range of respiratory diseases such as asthma, bronchitis, and even emphysema. The particle size is so minute that they can penetrate deep into the lungs, where they can cause irreparable damage.

Gases: The Silent Asphyxiants and Irritants

In addition to solid particulates, welding processes also generate a variety of dangerous gases. These include carbon monoxide, carbon dioxide, ozone, and nitrogen oxides. Carbon monoxide is particularly dangerous as it binds with hemoglobin in the blood, preventing oxygen transport and leading to asphyxiation. Carbon dioxide, while less toxic, can also displace breathable oxygen, especially in poorly ventilated or confined spaces. Ozone and nitrogen oxides are potent respiratory irritants that can cause severe lung inflammation and damage. The use of shielding gases like argon and helium, though inert, also poses a risk in enclosed areas by displacing oxygen, creating an immediate asphyxiation hazard. This highlights the critical need for proper welding ventilation in all work environments.

Types of Welding Ventilation Systems: A Layered Approach to Safety

An effective welding ventilation system is the single most important control measure for mitigating the risks of fume and gas exposure. The primary objective is to capture and remove the contaminants at their source before they can be inhaled. There are several types of systems, each with its own advantages and best applications.

1. Local Exhaust Ventilation (LEV)

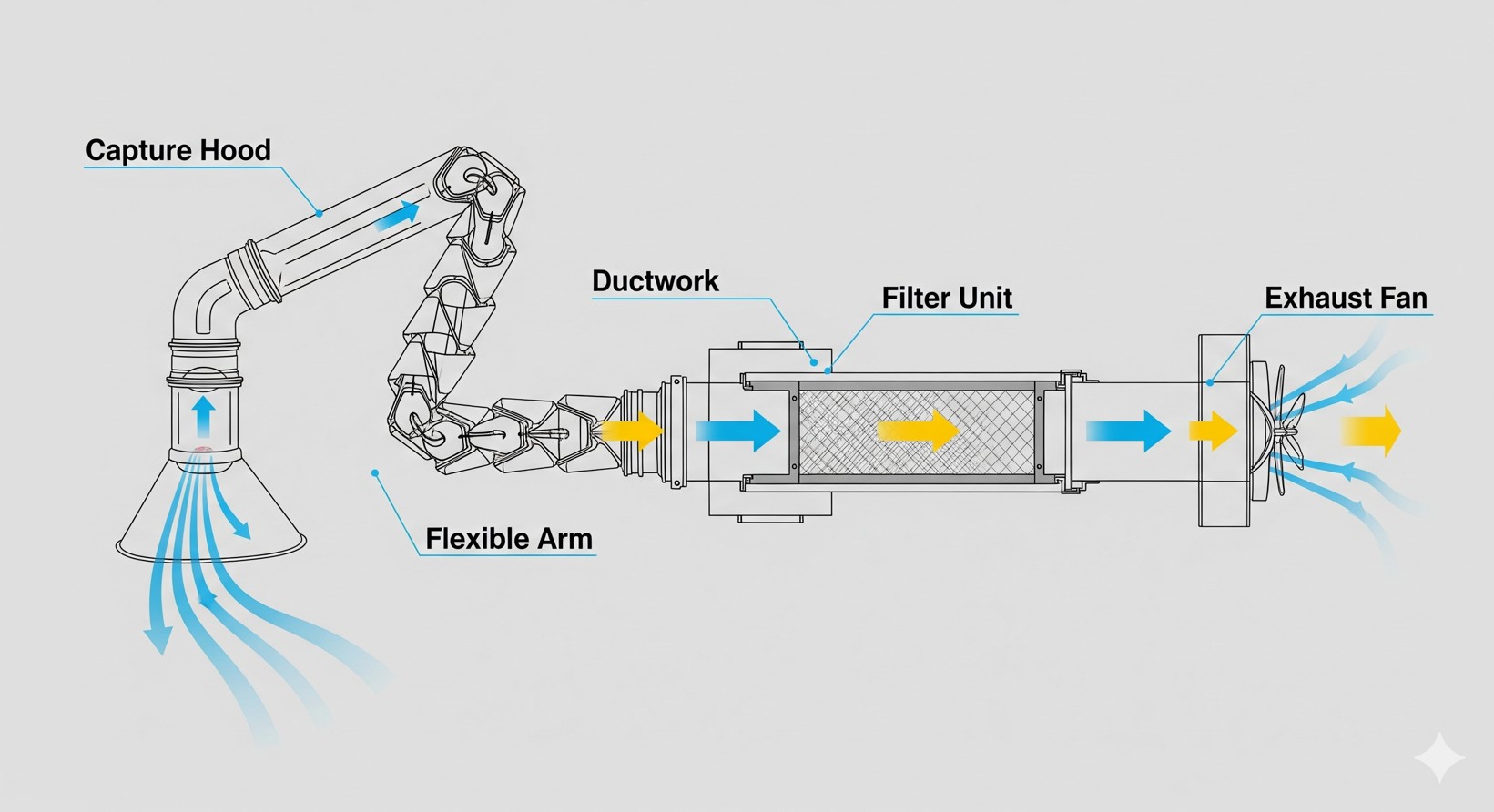

Local Exhaust Ventilation, or LEV, is the gold standard for controlling welding fumes. It works by capturing the fumes and gases at or very near their point of origin. This is achieved using a system that includes a capture hood, a ductwork system, a fan, and a filter or exhaust. The contaminated air is drawn in, filtered to remove particulates, and then either exhausted outside or, in some cases, recirculated back into the facility after proper treatment. LEV systems are highly effective because they prevent the contaminants from spreading throughout the workspace. They are the preferred method for stationary welding stations and are required in many jurisdictions.

Sub-Types of LEV Systems:

- Fume Extractor Arms: These are flexible, articulated arms that can be positioned by the welder directly over the work area to capture fumes at the source. They are highly adaptable and effective for a wide range of tasks.

- Portable Fume Extractors: As the name suggests, these are mobile units that can be moved to different work areas. They are ideal for workshops where welding tasks are not confined to a single bay. These units typically have a fan, a filter, and a flexible hose with a capture hood.

- Welding Fume Extraction Guns: These are highly integrated solutions where the fume extraction nozzle is built directly into the welding torch itself. This offers the most immediate and efficient capture, as the fumes are collected at the exact moment they are generated, minimizing the welder’s exposure.

2. General Ventilation (Dilution Ventilation)

General ventilation, or dilution ventilation, involves using fans to circulate and dilute the concentration of fumes and gases in the entire workspace. This is the least effective method for controlling welding fumes and should only be used in very specific, low-volume scenarios where LEV is not feasible, and always in combination with personal protective equipment (PPE). The primary drawback is that it does not prevent exposure at the source; instead, it simply lowers the overall concentration in the air. This method is often insufficient to meet OSHA’s Permissible Exposure Limits (PELs) for many hazardous substances.

3. Personal Protective Equipment (PPE)

While not a ventilation system, respiratory protective equipment (RPE) is a critical component of a comprehensive safety program. It should always be used as a last line of defense, supplementing engineering controls like ventilation, not replacing them. RPE includes a range of devices, from simple disposable respirators to advanced powered air-purifying respirators (PAPRs). The choice of respirator depends on the specific hazards present and the concentration of fumes. It is imperative that welders are properly fit-tested for their respirators and trained on their correct use and maintenance.

Best Practices for Implementing an Effective Welding Ventilation System

Successfully implementing a welding ventilation system requires more than just installing equipment. It involves careful planning, regular maintenance, and a commitment to a culture of safety.

1. Conducting a Hazard Assessment

The first step is to identify all potential hazards. This involves understanding the materials being welded (e.g., mild steel, galvanized steel, stainless steel, aluminum), the welding process (e.g., MIG, TIG, Stick), and the electrodes or filler materials used. Each combination produces a unique fume and gas profile that dictates the required ventilation solution. For example, welding stainless steel releases hexavalent chromium and nickel, both of which are highly carcinogenic and require robust controls.

2. Ensuring Proper Airflow and Capture Velocity

The effectiveness of an LEV system is determined by its airflow, measured in cubic feet per minute (CFM), and its capture velocity. The capture velocity is the speed at which the air is drawn into the capture hood, which must be strong enough to overcome the natural updraft of the hot welding plume. A common mistake is positioning the capture hood too far from the source. The closer the hood is to the arc, the more effective the capture and the lower the required airflow. Proper positioning and regular monitoring of airflow are essential.

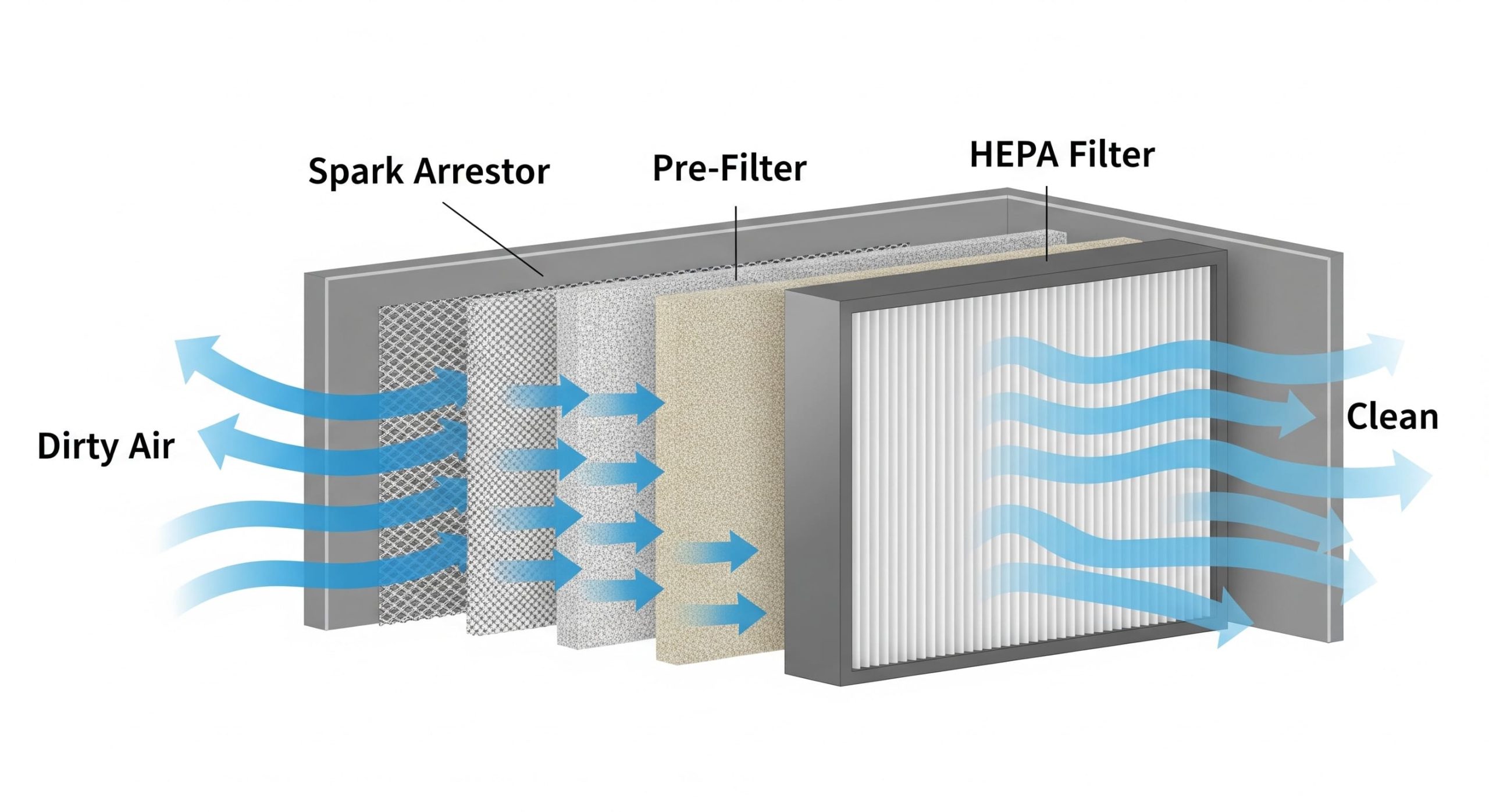

3. Filtration and Exhaust Management

A modern ventilation system uses a multi-stage filtration process. This typically includes a spark arrestor to prevent fire hazards, a pre-filter to capture larger particles, and a final, high-efficiency particulate air (HEPA) filter to trap the fine, sub-micron particles. For systems that recirculate air back into the facility, these filters are non-negotiable and must be meticulously maintained. The exhaust for systems that vent outside must be located away from air intakes, windows, or any occupied areas to prevent re-entry of contaminants. Regular filter changes are critical to maintaining system efficiency and protecting the fan motor from undue stress.

4. Establishing a Maintenance Protocol

A poorly maintained ventilation system is ineffective. Establish a rigorous maintenance schedule that includes regular inspections of ductwork for leaks, cleaning of hoods and arms, and timely replacement of filters. Clogged filters dramatically reduce airflow and can lead to system failure. Employee training on system use and maintenance is also crucial for ensuring the longevity and effectiveness of the equipment.

Regulatory Compliance and The Path to a Safer Workplace

Compliance with health and safety regulations, such as those set by OSHA in the United States, is not optional. OSHA establishes Permissible Exposure Limits (PELs) for a vast number of hazardous substances, including those found in welding fumes. Employers are legally and ethically obligated to implement engineering controls, with welding ventilation being the primary example, to meet or exceed these limits. In addition to ventilation, a comprehensive safety program should include:

- Training: All welders must be trained on the specific hazards of the materials they work with, the proper use of ventilation equipment, and the correct use of PPE.

- Monitoring: Regular air quality monitoring should be conducted to ensure that fume concentrations are within safe limits.

- PPE Program: A formal respiratory protection program should be in place, including fit-testing for respirators and medical evaluations for workers who use them.

For more information on occupational safety standards, you can visit the websites of relevant organizations:

- NIOSH (National Institute for Occupational Safety and Health)

- ANSI (American National Standards Institute)

- Best Welding Helmets Review

Final Thoughts

The health risks associated with welding are significant but entirely manageable with the correct approach to safety. Proper welding ventilation is the cornerstone of this approach. By understanding the dangers, investing in the right equipment, and maintaining a steadfast commitment to regulatory compliance and best practices, we can protect the well-being of welders and ensure a healthier, more productive work environment for everyone. An investment in ventilation is not merely a financial expenditure; it is an investment in human life and the long-term sustainability of any business that relies on the art and science of welding.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!