Welcome to the fascinating world of plasma cutting, a technology that has revolutionized the metal fabrication industry. At the heart of this process is an incredibly hot, electrically conductive gas known as plasma. But what exactly makes this gas so effective at slicing through metal? It all comes down to the type of gas used. The choice of gas, or a mixture of gases, is not a minor detail—it’s a critical factor that dictates everything from the cutting speed and quality to the cost of operation and the type of material you can cut.

Understanding the different gases used in plasma cutting is essential for anyone from a seasoned professional to a hobbyist just starting out. Each gas has its own unique properties and is best suited for specific applications and materials. This article will provide a comprehensive and in-depth look at the various gases used in plasma cutting, exploring their individual characteristics, advantages, disadvantages, and optimal applications. We will also delve into the science behind how these gases work to create the powerful plasma arc and help you make an informed decision for your next project.

The Science of Plasma Cutting: From Gas to Arc

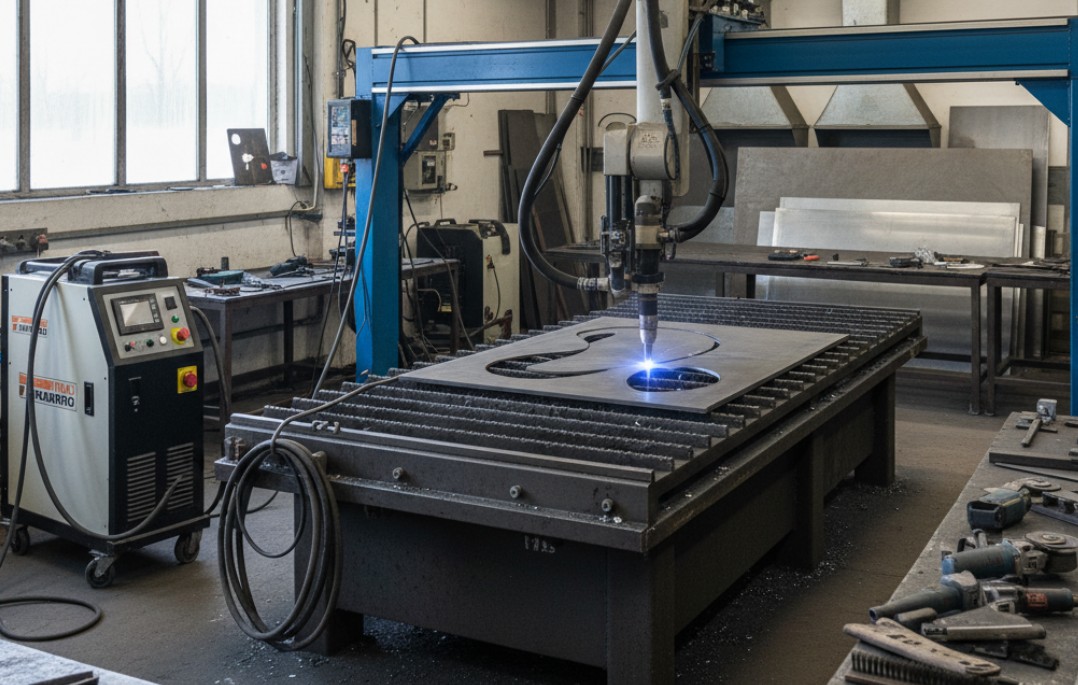

Before we explore the specific gases, it’s important to understand the fundamental principle of how a plasma cutter works. At its core, a plasma cutter is a device that uses a stream of superheated, ionized gas to melt and blast away material from a workpiece. The process begins with a gas, which can be air or a specialty gas, being fed into the torch. An electric arc is then generated between an electrode (cathode) inside the torch and the metal workpiece (anode).

As the gas passes through this electric arc, it becomes superheated and undergoes a process called ionization. This process strips electrons from the gas atoms, transforming the gas into a fourth state of matter: plasma. This plasma is then constricted by a nozzle, which forces it into a narrow, high-velocity jet. The moment this high-temperature, high-velocity plasma jet contacts the workpiece, it melts the metal. The sheer force of the gas stream then blows the molten metal away, creating a clean cut or “kerf.” The type of gas used is what determines the temperature and kinetic energy of this plasma jet, and ultimately, the quality of the cut.

For more information on the machines themselves, you can check out our guide on the best plasma cutters available on the market.

The Main Players: Common Plasma Cutting Gases

When you are considering what gases are used in plasma cutters, you will typically encounter a few primary options. The most common gases are compressed air, oxygen, nitrogen, and a mixture of argon and hydrogen. Each of these has a unique profile of characteristics that makes it suitable for different materials and applications. Let’s break down each one to understand its strengths and weaknesses.

1. Compressed Air: The Jack-of-All-Trades

Compressed air is, without a doubt, the most common and versatile gas used in plasma cutting. It’s readily available, inexpensive, and can be used on a wide range of materials, including mild steel, stainless steel, and aluminum. The main reason for its popularity is its practicality. You don’t need to purchase or manage separate gas cylinders, as a simple air compressor is all that’s required. This is a significant advantage, especially for smaller workshops or mobile applications.

Advantages of Compressed Air:

- Economical: The cost of compressed air is negligible compared to other specialty gases, drastically reducing operating costs.

- Versatility: It performs well on a variety of conductive metals, making it a great all-purpose choice for general fabrication.

- Portability: Many modern plasma cutters, especially those designed for hobbyists and DIYers, come with a built-in air compressor, allowing for ultimate portability. This is a key feature of the best plasma cutters with built-in air compressor.

Disadvantages of Compressed Air:

- Cut Quality: While versatile, the cut quality is often not as clean as that produced by other gases. The presence of oxygen and moisture in the air can lead to oxidation on the cut surface, leaving a dark, rough edge and requiring post-cutting cleanup.

- Consumable Life: The oxygen and nitrogen in the air can accelerate the wear on the torch’s consumables, such as the electrode and nozzle. This can lead to more frequent replacements and slightly higher long-term costs.

Despite these drawbacks, for a vast majority of users, compressed air offers an excellent balance of performance, economy, and convenience. It’s the go-to choice for most manual and light-duty plasma cutting applications.

2. Oxygen: The King of Mild Steel

If you are exclusively cutting mild steel, there is no better gas for the job than oxygen. Oxygen is considered the industry standard for cutting mild steel because it provides an exceptionally clean, high-quality cut with minimal dross. The reason for this is a chemical reaction—the oxygen in the plasma jet reacts with the carbon in the steel, creating a finer spray of molten metal that is more easily ejected from the cut. This results in faster cutting speeds and a very smooth, dross-free surface.

Advantages of Oxygen:

- Superior Cut Quality: Oxygen produces the cleanest and smoothest cuts on mild steel, often eliminating the need for secondary cleanup.

- High Speed: The chemical reaction between the oxygen and the mild steel allows for significantly faster cutting speeds, boosting productivity.

- Reduced Dross: The molten metal has a lower surface tension, making it easier to blow away, which leaves behind a very clean edge.

Disadvantages of Oxygen:

- Material Limitation: Oxygen is not recommended for cutting non-ferrous metals like aluminum or stainless steel. It can lead to severe oxidation and a very poor-quality cut on these materials.

- Higher Cost: Oxygen gas is more expensive than compressed air, and the chemical reaction with the electrode can shorten the life of consumables, increasing operating costs.

- Safety: As with any welding gas, proper handling and storage are crucial to ensure safety.

Oxygen is the top choice for industrial applications where the primary material is mild steel and a pristine cut is a priority.

3. Nitrogen: The Choice for Stainless and Aluminum

Nitrogen is a popular choice for cutting stainless steel and aluminum, especially in high-definition or mechanized cutting systems. It’s an inert gas, which means it doesn’t react with the metals being cut, thus preventing oxidation on the cut surface. This results in a bright, shiny, and smooth finish that is highly desirable for aesthetic or precision applications.

Advantages of Nitrogen:

- Excellent Cut Quality: Nitrogen provides a very clean, bright, and smooth cut on stainless steel and aluminum, without the dark oxide layer that compressed air can leave behind.

- Long Consumable Life: As an inert gas, nitrogen is less aggressive on consumables than oxygen, which can extend their lifespan.

- Versatility for Non-Ferrous Metals: It’s the most widely used gas for cutting a variety of non-ferrous metals.

Disadvantages of Nitrogen:

- Dross Formation: While the top edge is clean, the bottom edge of the cut may have some dross that requires removal.

- Higher Cost: Nitrogen gas is more expensive than air, and requires a separate gas cylinder, adding to the initial setup cost.

Nitrogen is often used as a plasma gas in conjunction with a secondary shield gas, such as air or CO2, to improve cut quality and efficiency. This combination is particularly effective for thicker materials.

4. Argon-Hydrogen: The Powerhouse for Thick Materials

For cutting very thick materials, especially stainless steel and aluminum, the mixture of argon-hydrogen (typically 65% argon, 35% hydrogen, also known as H-35) is the undisputed champion. This mixture creates an extremely hot plasma arc, capable of the highest cutting speeds and maximum cutting capacity of any plasma gas. The hydrogen in the mixture dissociates and recombines at high temperatures, releasing a tremendous amount of energy that intensifies the heat of the arc.

Advantages of Argon-Hydrogen:

- Maximum Cutting Capacity: This mixture is ideal for cutting very thick plates of stainless steel and aluminum, often exceeding 3 inches in thickness.

- Highest Speed: It offers the fastest cutting speeds on thick, non-ferrous metals.

- Exceptional Cut Quality: It produces a very straight, smooth cut with an almost polished surface on stainless steel.

Disadvantages of Argon-Hydrogen:

- High Cost: Both argon and hydrogen are expensive gases, making this option less economical for everyday use.

- Material Limitation: It is not recommended for cutting mild steel.

- Safety: Hydrogen is a highly flammable gas, and its use requires specialized equipment and strict safety protocols.

Argon-hydrogen is a specialized gas mixture used in high-amperage, industrial-grade plasma cutting systems where speed and cut quality on very thick materials are the primary concerns.

5. Other Gases and Mixtures

In addition to the main four, other gases and gas mixtures are used for specific applications:

- Argon: Argon is an inert gas that is sometimes used on its own, but its low electrical conductivity and heat transfer properties make it slow for cutting. It is more commonly used for plasma gouging or marking.

- Nitrogen-CO2: A mixture of nitrogen and carbon dioxide can be used as a plasma gas to improve cut quality on certain materials and to extend the life of consumables.

- Nitrogen-Water: Some specialized systems use a nitrogen plasma gas with a water shield. This combination is known for producing exceptionally clean and bright cuts on stainless steel and aluminum by preventing oxidation.

Choosing the Right Gas for Your Application

Making the right choice of gas for your plasma cutter depends on a few key factors. You need to consider the material you are cutting, the thickness of that material, your desired cut quality, and your budget.

1. For General-Purpose Cutting:

If you’re a hobbyist or a small shop owner who works with a variety of materials and thicknesses, compressed air is the best and most economical choice. It provides a good balance of performance and low operating cost, and the convenience of a built-in compressor can’t be overstated.

2. For Mild Steel Fabrication:

If your work is focused on mild steel, particularly in a production environment, oxygen will provide the best results in terms of cut quality and speed. The investment in the gas and consumables will be offset by the time saved on post-cutting cleanup.

3. For Stainless Steel and Aluminum:

When working primarily with stainless steel or aluminum, nitrogen is the go-to gas. It will provide the best cut quality and a bright, clean finish. For thicker plates, consider a more powerful system that can utilize an argon-hydrogen mixture for optimal speed and cut quality.

4. For Heavy-Duty Industrial Applications:

In high-amperage, mechanized systems cutting very thick metals, the choice is often between a combination of gases. For example, a nitrogen plasma gas with an air or CO2 shield gas for thinner non-ferrous metals, or the powerful argon-hydrogen mixture for very thick stainless and aluminum.

Beyond Gas: The Importance of Gas Flow Rate and Pressure

The type of gas is only part of the equation. The gas flow rate and pressure are also critical to achieving a good cut. The gas flow rate, measured in cubic feet per hour (CFH) or liters per minute (LPM), and the pressure, measured in pounds per square inch (PSI), must be correctly set according to the manufacturer’s specifications for your machine, torch, and the specific application.

If the gas pressure is too low, the molten metal will not be adequately blown away, resulting in a lot of dross and a poor-quality cut. Conversely, if the pressure is too high, it can lead to a less stable arc, a wider kerf, and a reduced consumable life. Therefore, always consult your machine’s manual and the cutting chart for the recommended settings for the material and thickness you are working with.

Final Thoughts

The world of plasma cutting gases is diverse, with each gas offering a unique set of benefits and limitations. While compressed air is the most common and practical choice for its versatility and low cost, specialized gases like oxygen, nitrogen, and argon-hydrogen are essential for achieving professional-grade results on specific materials. Making the right choice is about more than just power; it’s about matching the gas to your specific application to optimize cut quality, speed, and cost. By understanding the properties of each gas and how they interact with different metals, you can unlock the full potential of your plasma cutter and elevate your work to the next level.

Ultimately, the best gas for your plasma cutter is the one that best suits your needs. Consider your most frequent projects, your budget, and the level of cut quality you require. Whether you stick with the convenience of air or invest in a multi-gas system, a solid understanding of these gases is a fundamental step toward becoming a master of plasma cutting.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!