In the world of metal fabrication, achieving a perfect, high-quality weld is the ultimate goal. While many welding processes exist, few offer the level of precision, control, and efficiency as plasma arc welding (PAW). This advanced technique, often considered an evolution of Gas Tungsten Arc Welding (GTAW) or TIG welding, utilizes a highly concentrated and superheated plasma jet to create exceptionally clean and strong welds.

Whether you’re a seasoned fabricator, an engineer looking for a reliable joining method, or a hobbyist curious about advanced processes, understanding the intricacies of plasma arc welding – process, benefits, and equipment is crucial. This comprehensive guide will explore the fundamental principles of PAW, break down its operational modes, and highlight why it’s a go-to choice for some of the most demanding industries in the world.

What is Plasma Arc Welding?

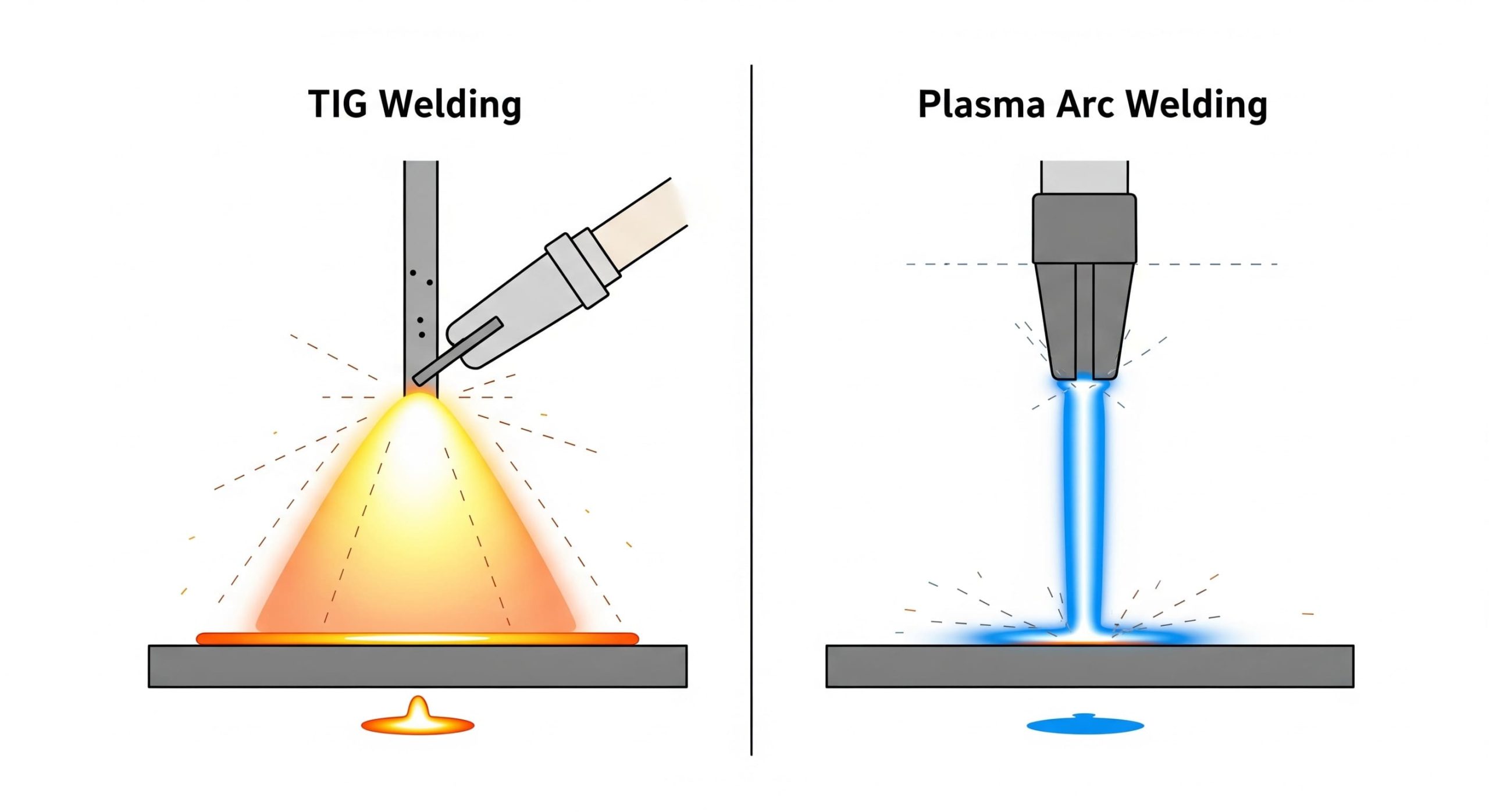

At its core, plasma arc welding is an arc welding process that uses a constricted arc. Unlike standard TIG welding, where the arc spreads out, PAW forces the arc through a fine-bore nozzle in the torch. This constricts and intensifies the plasma, creating a very narrow, highly focused, and extremely hot plasma stream. This stream, which can reach temperatures up to 30,000°F (16,650°C), is the primary heat source for melting and fusing the base metals.

The process relies on two distinct gas flows: an inner plasma gas and an outer shielding gas. The plasma gas, typically argon or a mix of argon and helium, is ionized by an electric arc to create the plasma. The shielding gas, usually argon, protects the weld puddle and the electrode from atmospheric contamination, ensuring a clean and strong weld. This dual-gas system is a defining feature of PAW and provides the stability and control necessary for intricate work.

The distinction between Plasma Arc welding and TIG welding is subtle yet fundamental. In TIG welding, the tungsten electrode is positioned close to the workpiece, and the arc is not constricted. The resulting heat zone is wider, which can cause more material distortion. In contrast, plasma arc welding keeps the electrode safely recessed within the torch, and the constricted arc provides a narrow, columnar heat source that offers superior control, deeper penetration, and a smaller heat-affected zone (HAZ). This allows for welding at higher travel speeds and with more precise results, making PAW a superior choice for many applications where weld quality is paramount.

The versatility of PAW also allows it to be used on a wide array of materials, from thin foils and sheets to thick plates, with exceptional results. Its ability to produce high-quality welds with minimal spatter and distortion makes it a preferred method in industries where aesthetic and structural integrity are non-negotiable.

The Plasma Arc Welding Process: Keyhole and Melt-in Modes

The unique capabilities of plasma arc welding are best understood through its two primary operational modes: melt-in and keyhole. Each mode is suited for different material thicknesses and applications, showcasing the process’s incredible versatility.

Melt-in Mode

The melt-in mode is used for welding thin materials, typically up to 2.5 mm (0.1 inches) in thickness. In this mode, the plasma arc is a gentle, low-current heat source that melts the surface of the base metals to form a weld puddle. It operates similarly to TIG welding but with a more focused arc. The electrode is positioned so that the arc’s heat is transferred to the workpiece, creating a wide, shallow bead.

Because the melt-in mode operates at lower current levels, it is ideal for welding delicate components where a large heat-affected zone would cause warping or damage. It’s the go-to method for joining foils, bellows, and thin-walled tubing used in medical and aerospace applications. This mode offers a high degree of control, allowing operators to create clean, aesthetically pleasing welds with minimal effort.

Keyhole Mode

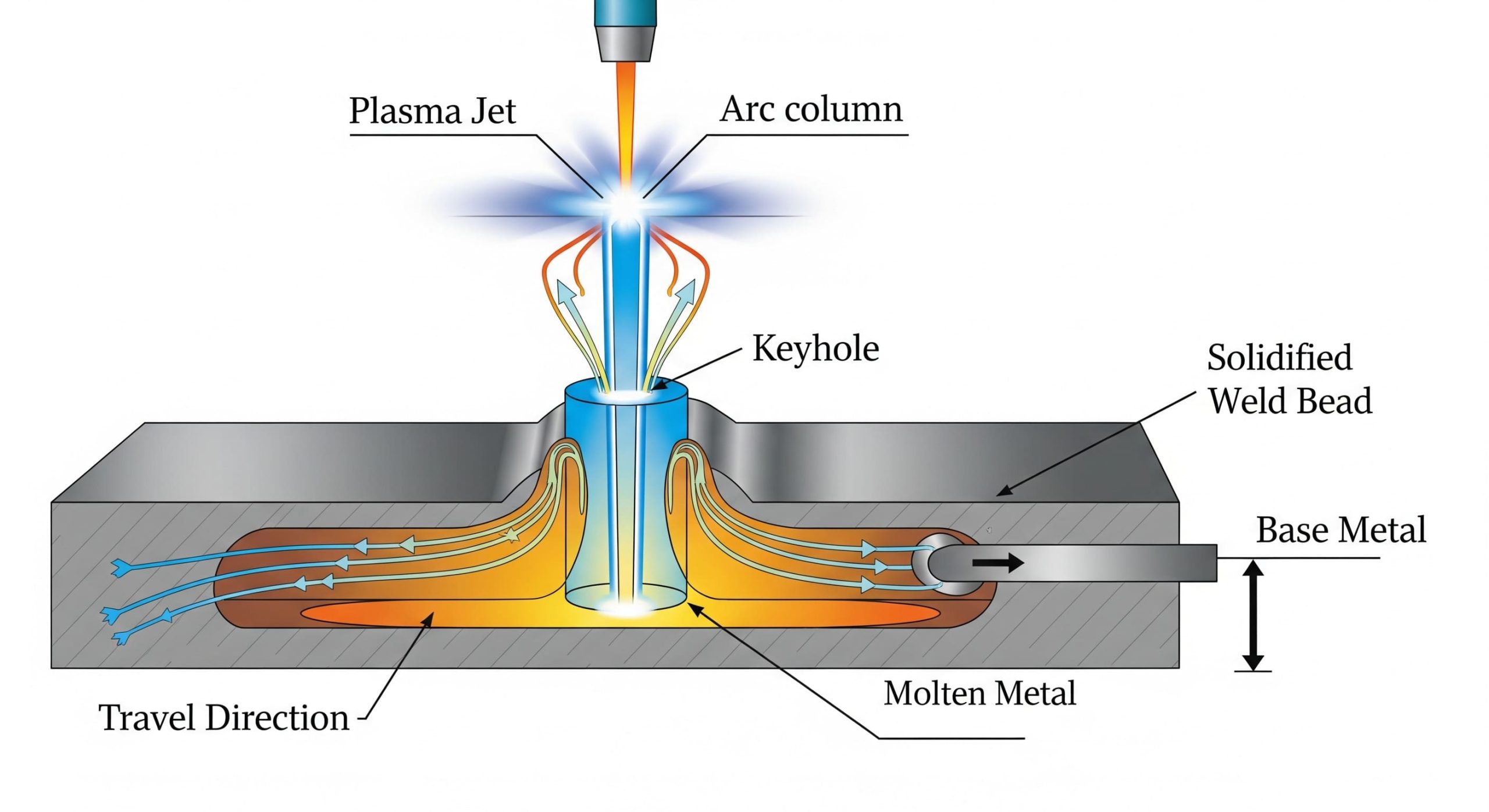

The keyhole mode is what truly sets plasma arc welding apart from other processes. When welding thicker materials (above 2.5 mm), the current is increased to the point where the plasma jet is powerful enough to pierce completely through the workpiece, creating a molten hole, or “keyhole.” The torch then travels along the joint, and the molten metal flows around the keyhole to fill the gap behind the arc, solidifying into a deep, full-penetration weld.

This technique offers several advantages. The full-penetration weld is achieved in a single pass, which significantly reduces welding time and labor compared to multi-pass TIG or MIG welding. The keyhole effect also allows for higher travel speeds, further boosting efficiency. This makes it particularly valuable for high-production environments where speed and quality are equally important.

Furthermore, the keyhole mode’s high power density and deep penetration make it possible to weld materials that would be difficult or impossible to join with other processes. It is used extensively in industries like shipbuilding and pipe welding, where strong, deep, and reliable welds are essential for structural integrity. The consistent and repeatable nature of the keyhole mode also makes it well-suited for automation, which is a major factor in modern manufacturing.

Key Equipment for Plasma Arc Welding

To perform plasma arc welding, a set of specialized equipment is required. While some components overlap with TIG welding, others are unique to the PAW process. Understanding each component is essential for proper operation and maintenance.

Power Source

The power source for PAW is a constant current (CC) DC power supply, similar to those used for TIG welding. However, it must be capable of a higher open-circuit voltage to initiate and maintain the pilot arc. Modern power sources often feature advanced controls for adjusting current, slope, and gas flow, allowing for precise control over the welding process.

Plasma Welding Torch

The welding torch is the heart of the PAW system. It houses the non-consumable tungsten electrode, a copper constricting nozzle, and provides the pathways for both the plasma and shielding gases. The design of the torch is what enables the arc constriction that defines the process.

- Electrode: Typically made of tungsten, the electrode is recessed inside the torch and does not touch the workpiece. This protects the electrode and ensures a stable arc.

- Constricting Nozzle: A crucial component that focuses the arc into a narrow, high-velocity jet. The size of the nozzle orifice directly impacts the arc’s intensity and heat concentration.

- Cooling System: Due to the high heat generated by the constricted arc, PAW torches are almost always water-cooled. This prevents the torch and nozzle from overheating, ensuring consistent performance and a longer lifespan.

Gas System

The gas system for plasma arc welding is more complex than for other processes due to its dual-gas requirement.

- Plasma Gas: The inner gas, usually argon, is ionized to form the plasma. For welding materials like stainless steel, a small percentage of hydrogen can be added to the argon to increase the arc temperature and penetration.

- Shielding Gas: The outer gas, typically pure argon, flows around the plasma stream to protect the molten weld pool from the atmosphere. This prevents oxidation and ensures a clean, strong weld.

For a more in-depth look at the various gases used in plasma-related applications, you might want to read about what gases are used in plasma cutters, as many of the principles and gas types overlap.

Water Cooling System

As mentioned, a dedicated water cooling system is essential for most PAW setups. The high heat of the constricted arc would quickly destroy an air-cooled torch. The system circulates water or a coolant through the torch to dissipate heat, allowing for continuous, high-current welding without damaging the equipment.

Filler Metal

While PAW can be used without filler metal for autogenous welds (fusion of base metals only), it is often used with a separate filler wire or rod. The filler metal is fed into the weld puddle manually or by a wire feeder, just as in TIG welding. The filler material is chosen to match the base metal, ensuring a strong and compatible joint.

The Benefits of Plasma Arc Welding

The unique characteristics of the PAW process translate into a host of significant advantages over conventional welding methods.

Precision and Quality

The most notable benefit of plasma arc welding is its unparalleled precision. The focused arc allows for extremely narrow welds and minimal heat input, which results in very little material distortion or warping. The process produces a smooth, clean bead with minimal spatter and a small heat-affected zone, making it ideal for high-quality, finished components. The welds are exceptionally strong and have a high degree of metallurgical integrity.

Speed and Efficiency

In keyhole mode, PAW can achieve full-penetration welds in a single pass on materials up to 10 mm (3/8 inches) thick. This is a massive time-saver compared to TIG welding, which would require multiple passes and extensive joint preparation. The faster travel speeds in both melt-in and keyhole modes lead to increased productivity and lower operational costs.

Versatility

Plasma Arc welding is incredibly versatile. It can be used on a wide variety of materials, including stainless steel, titanium, nickel alloys, and copper. It can also be used on an impressive range of thicknesses, from extremely thin foils (0.02 mm) to thick plates. This makes it a go-to process for manufacturers who need to work with diverse materials and geometries.

Deeper Penetration

The keyhole mode of PAW provides a deeper, more consistent penetration than any other open-arc welding process. This capability is critical for applications that require a robust and reliable joint, especially in structural components where weld strength is paramount.

Operator Comfort

Because the tungsten electrode is recessed and the arc is constricted, the stand-off distance between the torch nozzle and the workpiece is greater than in TIG welding. This provides better visibility of the weld puddle and reduces the risk of arc-related burns or accidents. The arc itself is less intense than an open arc, which also contributes to a more comfortable and safer working environment.

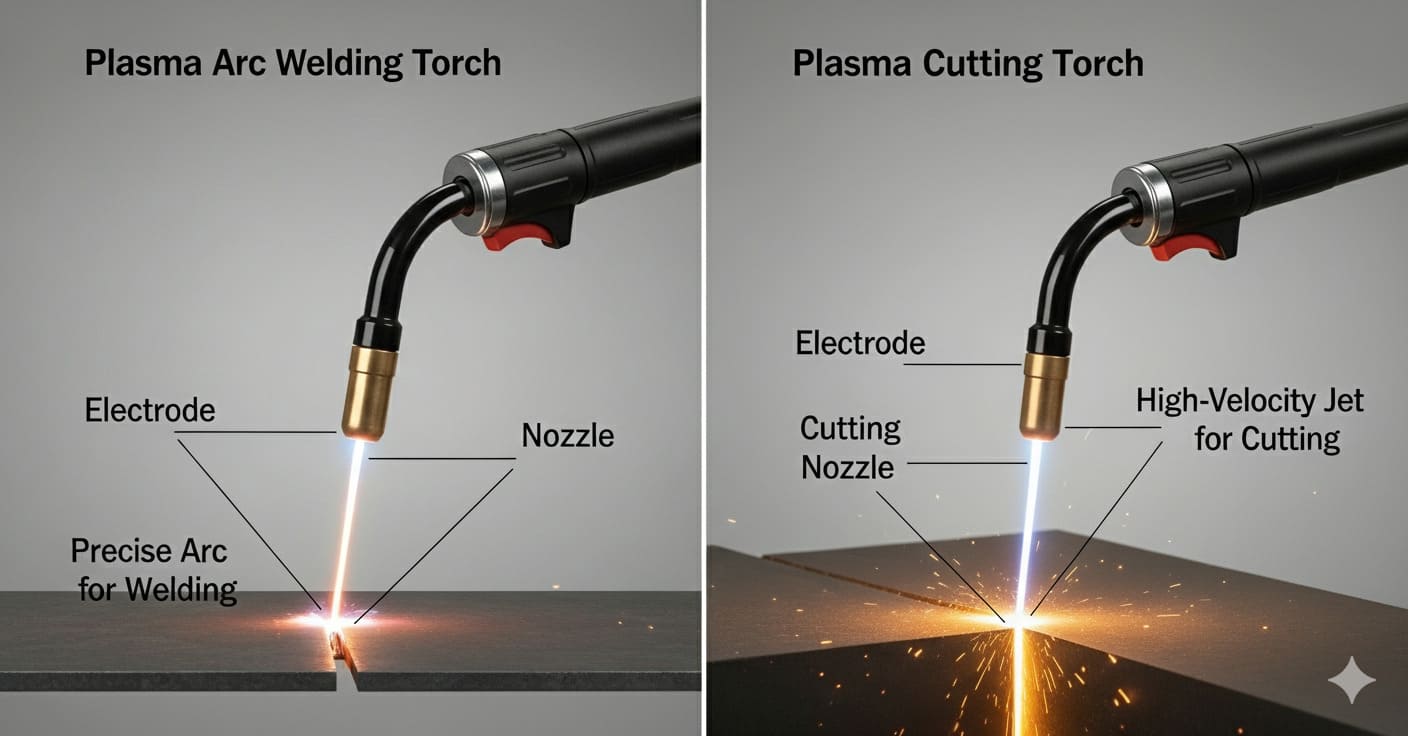

Plasma Arc Welding vs. Plasma Cutting

This is where a common point of confusion arises. Both processes utilize a plasma arc, but their fundamental purpose is completely different. Plasma arc welding is a joining process used to fuse two pieces of metal together, while plasma cutting is a severing process used to cut metal. The confusion is understandable since both processes use similar principles, but their equipment and applications are distinct.

A plasma cutter creates a very high-velocity, high-temperature plasma jet that is powerful enough to melt and blow away metal. Plasma cutters are designed for rapid, efficient cutting of conductive materials. The equipment is typically more portable and robustly built for job site use. If you’re looking for a cutting solution, you can explore the best plasma cutters available on the market.

Furthermore, some plasma cutters are designed with a built-in air compressor, which simplifies the setup process and makes the tool more portable. If you’re considering a cutter for on-the-go projects, you can learn more about the best plasma cutters with a built-in air compressor. For those using a separate plasma cutter, choosing the right compressor is crucial. The quality of your cuts depends heavily on a consistent, dry air supply. You can find out more about how to choose the right one in this guide on the best air compressors for plasma cutter.

In contrast, plasma arc welding is all about control and precision. The arc is specifically designed to transfer heat to the workpiece to melt it into a solid joint, not to blow it away. The gas flow and current settings are optimized for a stable, quiet arc that creates a smooth weld bead. The torch, while similar in principle, is built for fine, controlled movements rather than for rapid cutting. This distinction is critical to understanding which tool to use for a given task.

Applications of Plasma Arc Welding

Due to its precision and quality, plasma arc welding has become an indispensable process in industries where failure is not an option and where components must meet stringent quality standards.

Aerospace and Aviation

The aerospace industry relies on PAW for welding critical components made of lightweight and high-strength materials like titanium and aluminum alloys. Its ability to create high-integrity, minimal-distortion welds makes it perfect for fabricating jet engine parts, fuel tanks, and airframe structures where structural integrity is paramount.

Medical and Pharmaceutical

In the medical field, PAW is used for manufacturing surgical instruments, implants, and other devices. The welds must be clean, precise, and free of any defects that could compromise sterility or function. The ability to weld very thin materials with minimal heat input is a major advantage for these delicate applications.

Automotive Industry

PAW is used in the automotive industry for manufacturing components that require high-quality welds, such as exhaust systems, catalytic converters, and high-performance radiators. Its speed and efficiency also make it suitable for automated production lines, helping to lower manufacturing costs while maintaining high quality.

Pipe and Tube Welding

For critical pipe and tube applications, particularly in the oil and gas industry, the keyhole mode of PAW is a game-changer. It allows for single-pass, full-penetration welds on pipes, which is significantly faster and more efficient than multi-pass TIG welding. The resulting welds are robust and reliable, capable of withstanding high pressures and extreme conditions.

Safety Precautions in Plasma Arc Welding

As with any welding process, safety is of the utmost importance. Plasma arc welding has some unique safety considerations that should be addressed.

- High Voltage: PAW power sources can produce high open-circuit voltages to initiate the arc. Always follow manufacturer guidelines and use proper insulated gloves and equipment to prevent electric shock.

- Fumes and Gases: While the process itself is clean, welding certain materials can produce toxic fumes. Always work in a well-ventilated area or use a fume extraction system.

- UV Radiation: The plasma arc emits intense ultraviolet (UV) radiation, which can cause arc eye and skin damage. Always wear a proper welding helmet with a high shade rating (at least a shade 12 for high-current PAW) and long-sleeved clothing to protect your skin.

- Compressed Gases: Handle compressed gas cylinders with extreme care. Secure them properly to prevent them from falling and causing injury.

- Hot Metal and Spatter: Even though PAW produces minimal spatter, the workpiece will be extremely hot. Wear proper protective gear, including heat-resistant gloves and safety boots, and be aware of your surroundings.

Final Thoughts

Plasma arc welding is a sophisticated and highly effective process that has carved out its own niche in the world of metal fabrication. Its unique ability to create a highly concentrated plasma arc gives it an advantage in precision, speed, and versatility that few other processes can match. From the delicate welds on medical instruments to the robust joints in aerospace components, PAW proves its worth by delivering consistent, high-quality results.

By understanding the core principles—from the difference between melt-in and keyhole modes to the specific equipment required—you can appreciate why PAW is a premium solution for demanding applications. While it may require a greater initial investment than traditional TIG welding, the benefits in terms of productivity, weld quality, and the ability to handle a wider range of projects often far outweigh the cost. Ultimately, for any professional who values precision and efficiency, mastering or even just understanding plasma arc welding – process, benefits, and equipment is an essential step towards elevating your craft.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!