A generator is the cornerstone of emergency preparedness, but merely owning one isn’t enough. Many generator owners diligently check the oil and cycle the engine monthly, only to run it without a significant load. This practice, while helpful for battery and engine lubrication, fails to stress-test the machine’s full capability. The true measure of a generator’s reliability lies in its ability to produce and sustain its rated power under demand. The answer to guaranteeing this reliability is mastering how to perform a load test on your generator—a critical preventative maintenance procedure that simulates real-world failure conditions.

This comprehensive guide is designed for homeowners, small business managers, and maintenance personnel who rely on standby or portable power. We will explore the “why” and “when” of load testing, the risks of running a generator at light loads, and provide detailed, professional steps for safely conducting a meaningful test, whether you are using your actual house loads or specialized equipment.

Why Load Testing is Non-Negotiable Maintenance

The core purpose of load testing is simple: to confirm that the entire generator system—from the engine to the alternator and all controls—can function effectively, efficiently, and reliably at or near its maximum capacity. It’s a fitness test that separates a running engine from a capable power source.

Preventing Wet Stacking: The Diesel Killer

The most compelling reason, particularly for diesel generators, is preventing a phenomenon known as wet stacking. Diesel engines are designed to operate under heat and pressure. When a diesel generator runs at less than 30% of its rated load (which is typical during a simple no-load exercise run), the engine never reaches its optimal operating temperature. Consequently, fuel doesn’t combust completely, resulting in unburnt fuel, carbon, oil, and moisture building up in the exhaust system and mufflers. This is the wet stack. Over time, this buildup compromises engine performance, causes excessive smoking, reduces efficiency, and can lead to irreversible damage to internal components like cylinder liners and turbochargers. A periodic, full-load test burns off these deposits, effectively “cleaning” the engine and extending its lifespan.

Stress-Testing the Electrical Components

Load testing is the only way to verify the functionality of the generator’s electrical heart, including the Automatic Voltage Regulator (AVR) and the alternator windings. When a heavy load is applied, the AVR must immediately adjust the current to the exciter windings to maintain a steady output voltage and frequency (typically 120V/240V and 60Hz). A full load test ensures that:

- The cooling system can handle the high operating temperatures.

- The fuel system (pump, lines, filters) can deliver the maximum required fuel flow without starving the engine.

- The AVR can react quickly to maintain stable voltage under sustained stress.

- The electrical windings and connections can handle the maximum amperage without overheating or failing.

When and How Often to Perform a Load Test

The frequency of load testing depends heavily on the generator’s purpose and whether it runs regularly under a substantial load.

Standby Generators (Home and Commercial)

For standby generators—including whole house generators that you can investigate further here—which often sit idle for long periods, annual testing is the professional standard. National Fire Protection Association (NFPA) standards often require annual testing at 75% capacity or more for a specified duration (often 1-2 hours) for critical applications (like hospitals or data centers). Even for residential units, an annual test is the best practice for peace of mind.

Portable and Construction Generators

For portable home backup generators, the testing schedule is more flexible but should occur at least once every six months if the unit is primarily stored. If the unit is used frequently for construction or heavy work, ensure it runs at near full capacity at least every 50-100 hours of operation to maintain optimal function.

Method 1: The Building Load Test (For Standby Units)

The Building Load Test uses the actual loads in your home or facility to test the generator. This is the most realistic test, as it includes the transfer switch and simulates the real sequence of an outage. However, it requires an Automatic Transfer Switch (ATS) or Manual Transfer Switch (MTS).

Step-by-Step Building Load Test Procedure

1. Pre-Test Inspection and Calculation

- Calculate Your Load: Before starting, know your generator’s rated kW capacity. Then, calculate your typical running load, ensuring you have enough appliances and systems turned on to reach at least 50% to 75% of that capacity.

- Physical Inspection: Perform a thorough pre-test check. Verify fuel levels, oil levels, coolant levels (if liquid-cooled), and inspect all belts and hoses. Ensure the generator is positioned safely and follow all necessary generator health and safety tips outlined in resources like this safety guide.

- Instrumentation: You will need a way to monitor the output, typically with the generator’s built-in control panel display, which shows voltage (V), frequency (Hz), and amperage (A) or kilowatts (kW).

2. Initiating the Test

- Warm-up: Start the generator (either manually or by initiating a test cycle on the ATS/control panel). Allow the engine to run for 10-15 minutes at no load to reach normal operating temperature.

- Transfer the Load: If you have an ATS, initiate a simulated power outage (often a button on the ATS or generator controller). If you have an MTS, manually switch the main breaker from ‘UTILITY’ to ‘GENERATOR’. The generator should accept the entire building load, which should bring it up to your target load percentage (50%-75%).

3. Monitoring and Sustaining the Load

- Monitor Key Parameters: For the next 1 to 2 hours, continuously check the control panel. The voltage should remain stable (e.g., 240V ± 5%) and the frequency should remain steady (e.g., 60Hz ± 3%).

- Listen and Look: Listen for any abnormal noises, excessive vibration, or smoke. Check engine temperature and oil pressure. If the generator struggles, overheats, or the voltage/frequency fluctuates widely, stop the test immediately and shut down the generator.

4. Cooling Down and Return to Standby

- Unloading: Once the test duration is complete, you must remove the load. For an ATS, simply end the test cycle, and the switch will return to utility power. For an MTS, switch the main breaker back to ‘UTILITY’.

- Cool-down: Allow the generator to run at no load for 5 to 10 minutes before shutting it off. This critical cool-down period allows the engine and turbocharger to stabilize temperatures and prevents thermal shock.

- Final Check: Once cool, check fluid levels again and place the generator control panel back into ‘AUTO’ or ‘STANDBY’ mode.

Method 2: The Load Bank Test (The Gold Standard)

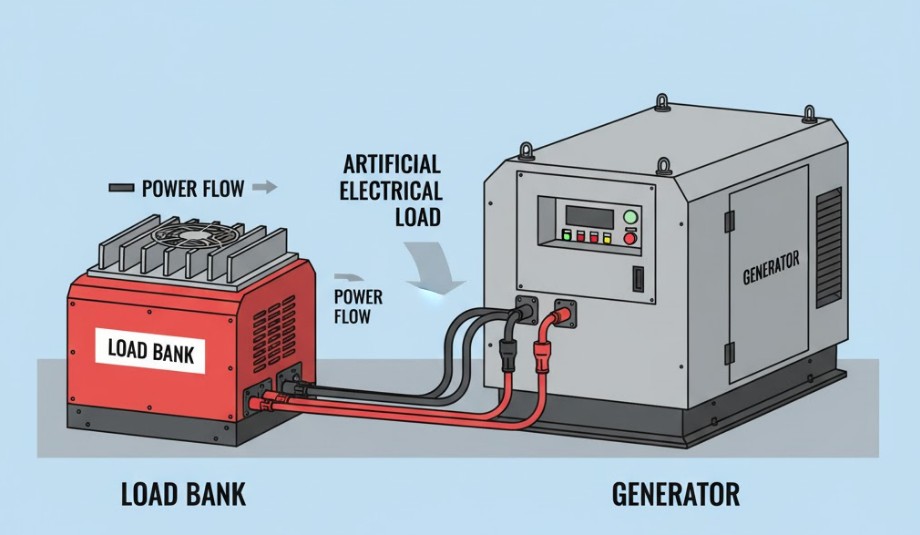

A Load Bank Test is the most definitive way to test a generator. It utilizes a specialized, external device called a load bank—a piece of equipment that provides an artificial, calibrated electrical load to the generator. This method is preferred because it can easily load the generator to 100% capacity without disrupting your home or business operations. This test is typically performed by professional generator technicians due to the specialized equipment and technical knowledge required.

Understanding the Load Bank

A load bank contains large resistive elements (like giant heating coils) that draw current, simulating the electrical demand of a building. Load banks allow the technician to apply the load incrementally—for example, in 25 kW steps—to observe how the generator reacts to sudden load changes and sustained maximum demand. This is often crucial for preventing the long-term issue of wet stacking.

Step-by-Step Load Bank Test Procedure (Professional Level)

1. Preparation and Connection

- Inspection: The technician conducts a thorough inspection, confirming fuel, oil, and coolant are optimal. They verify the generator’s nameplate ratings (kW, voltage, amperage).

- Load Bank Setup: The load bank is positioned near the generator. Heavy-gauge cables are used to safely connect the load bank terminals to the generator’s output terminals or a dedicated load bank breaker. Safety is paramount: All connections must be secure and the area clear of personnel.

- Measurement Tools: External meters (voltmeter, ammeter, frequency meter) are connected to provide highly accurate, independent readings of the generator’s output, independent of the generator’s internal display.

2. Incremental Loading

- Warm-up: Start the generator and run at no load for 10-15 minutes until operating temperature stabilizes.

- 25% Load: The technician applies the first load step, usually 25% of the generator’s rated kW capacity. They monitor the key parameters (V, Hz, A) and record the data.

- 50% Load: The load is increased to 50% capacity. This step is often where minor fuel or cooling system issues first become apparent.

- 75% Load: The load is increased to 75% capacity. The generator is monitored for stable output, exhaust clarity, and engine health.

- 100% Load: The final load is applied, bringing the generator to its full rated capacity. This full load is maintained for the prescribed duration (often 1-2 hours) to ensure the engine and alternator can handle the maximum sustained stress. This is the stage that effectively burns off any wet stacking.

3. Data Recording and Analysis

Throughout the test, critical data is recorded at each load step and at regular intervals during the sustained 100% run. This typically includes:

- AC Voltage and Amperage (on all legs)

- Frequency (Hz)

- Engine Oil Pressure and Temperature

- Coolant Temperature

- Fuel Consumption Rate

- Exhaust Temperature (optional, but highly informative)

The technician is specifically looking for any significant drop in voltage or frequency outside of acceptable tolerances (usually 5%) or any signs of overheating.

4. Cool-down and Shutdown

- Step-Down: After the test duration, the load is gradually removed in reverse increments (100% to 75% to 50%, etc.).

- Cool-down: The generator is then run at no load for 5-10 minutes before being shut down to prevent thermal shock and allow the turbocharger (if present) to cool safely.

- Disconnection: The load bank is safely disconnected and the generator is returned to ‘AUTO’ or ‘STANDBY’ mode.

Interpreting Load Test Results

A successful load test means the generator maintained a stable voltage and frequency within tolerance for the entire duration, and the engine parameters (temperature, oil pressure) remained normal. If the generator fails, it often points to a specific system issue:

- Voltage/Frequency Drop: Often indicates an issue with the AVR, alternator windings, or the engine’s ability to maintain the proper RPM (a sign of fuel or governor problems).

- Overheating: Points to a failure in the cooling system (low coolant, faulty thermostat, clogged radiator, or bad fan/pump).

- Excessive Smoke/Sputtering: Indicates wet stacking (if diesel) or a serious engine component failure (e.g., injector or piston ring problem).

A failed test demands immediate professional diagnosis and repair, as the issue will only be amplified during a real, critical power outage.

Maintenance and Proactive Measures

Load testing is not a standalone activity; it is part of a complete preventative maintenance program. Running the generator even without a load is part of good practice, as are routine visual inspections of the engine components, following safety guidelines, and keeping up with fluid changes.

Remember that whether you opt for a high-capacity whole house generator or a smaller, more flexible unit, proactive maintenance is crucial. Even the best generators, like the portable home backup generators available today, require periodic checks to ensure every component is ready to handle maximum demand. By making load testing a scheduled part of your maintenance, you move beyond merely checking a box; you actively certify the reliability of your most important backup power asset.

Final Thoughts on Load Testing Your Power Asset

Understanding how to perform a load test on your generator transforms it from a piece of parked machinery into a verified, reliable power asset. For smaller portable generators, simulating a realistic load with space heaters and tools is a good start. For critical standby units, investing in an annual professional load bank test is an essential investment that prevents catastrophic failures, safeguards sensitive equipment, and eradicates the long-term damage caused by wet stacking in diesel units. Treat your generator like the life-support system it is during an outage. By subjecting it to the stress of a full load, you ensure it is not just running, but truly ready to perform when your home or business needs it most.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!