In an age where reliable backup power is less of a luxury and more of a necessity, dual fuel generators have emerged as a highly versatile and popular solution. They offer the flexibility to run on both gasoline (petrol) and liquid propane (LP), giving homeowners and professionals a crucial advantage during extended outages or when one fuel source is scarce. However, owning one is only half the battle. The real challenge—and where significant savings lie—is in Maximizing Fuel Efficiency in Dual Fuel Generators.

Whether you’re preparing for storm season or powering a remote job site, getting the most runtime from every gallon of gasoline or pound of propane is paramount. This comprehensive guide will transition from basic understanding to advanced operational strategies, ensuring your dual fuel generator operates at its peak efficiency, saving you money, and extending your power security.

Understanding Dual Fuel Efficiency: The Basics

Before diving into optimization, it’s essential to understand *why* efficiency is a unique topic for these machines. A dual fuel generator doesn’t simply consume two fuels; it involves two distinct combustion processes, each with its own energy content, consumption rate, and efficiency profile.

Gasoline vs. Propane: A Direct Comparison

The first step in maximizing fuel efficiency is making an informed choice between the two fuels.

The Energy Density Difference

Gasoline has a higher energy density per unit of volume than propane. One gallon of gasoline contains roughly 114,000 BTUs (British Thermal Units) of energy, while a gallon of liquid propane contains about 91,500 BTUs. This difference means that, on a volume-per-volume basis, gasoline provides more raw power and generally longer runtime for the same volume of fuel. However, propane’s energy density changes when considering its pressurized state.

The Cost and Storage Factor

Propane, though less energy-dense, is often significantly cheaper per BTU, is easier to store indefinitely without degradation, and is cleaner burning. Gasoline begins to degrade quickly, potentially clogging carburetors and fuel lines, which ultimately *reduces* efficiency over time. Therefore, while propane might offer slightly lower wattage output (a common characteristic of dual fuel engines), its long-term storage stability makes it a more reliable and often more economical choice for standby power.

Therefore, our pursuit of maximum efficiency must consider both the fuel’s inherent properties and the operational context.

Load Management: The Single Most Important Factor

When it comes to generator efficiency, the load—the amount of power being drawn—is king. An improperly loaded generator is inherently inefficient, regardless of the fuel used.

The “Sweet Spot” for Optimal Operation

Generators are designed to run most efficiently within a specific load range. For most conventional generators, this sweet spot is between 50% and 75% of the unit’s rated capacity. Running a generator at less than 30% load, often called “light loading,” or exceeding 85% load severely compromises efficiency. When lightly loaded, the generator’s engine doesn’t reach its optimal operating temperature, leading to incomplete combustion, more wear and tear, and significantly higher fuel consumption per kilowatt-hour (kWh) of power produced.

If you’re unsure about the best loading percentage for your specific model, you might find valuable insights in this discussion on optimal standby generator loading percentage.

Strategies for Achieving Optimal Load

Load Shedding: Prioritize essential appliances (furnace, refrigerator, well pump) and temporarily disconnect non-essential, high-draw items (electric water heaters, clothes dryers). This stabilizes the load closer to the 50-75% efficiency range.

Staggered Start-up: Appliances with motors, like refrigerators and air conditioners, have a high “starting surge.” Starting all high-surge items simultaneously can temporarily overload the generator, causing it to work harder and less efficiently. Always start high-surge appliances one at a time, with a few minutes in between.

Whole house generators, while a different category, demonstrate the value of load management, as their transfer switches are often programmed to prioritize circuits, effectively managing the load for maximum efficiency.

Fuel-Specific Optimization Techniques

The pursuit of maximum fuel efficiency requires treating gasoline and propane differently, even within the same machine.

Propane Efficiency Tips: A Cleaner Burn

Propane is often the preferred fuel for long-term backup due to its superior shelf life, but it requires careful handling to ensure efficiency.

Tank and Hose Integrity

Ensure that the propane tank is not placed in direct sunlight, which can increase the internal pressure and cause the safety valve to vent, losing fuel. Furthermore, the hoses and fittings must be completely free of leaks. Even a small, slow leak can drastically deplete a tank over an extended run time. Always use the proper regulator, as the generator relies on a specific low-pressure flow for optimal combustion efficiency.

Temperature Considerations

Propane vaporizes best in warmer temperatures. In cold weather, the liquid propane inside the tank may not vaporize fast enough to meet the generator’s demand, especially under a heavy load. This results in the generator running ‘lean’ (too little fuel), which decreases efficiency and can sometimes cause the generator to stall. Keeping the tank in a moderately warmer, but well-ventilated, area (never indoors!) can improve the vaporization rate and fuel efficiency.

Gasoline Efficiency Tips: The Power Source

Gasoline delivers more raw power, but its efficiency is highly susceptible to fuel quality and engine health.

Fuel Stabilizer is Non-Negotiable

The single best way to maintain gasoline efficiency for a generator that sits idle for long periods is the use of a high-quality fuel stabilizer. Untreated gasoline can separate and form gum-like deposits in the carburetor and fuel lines within a few months. These clogs restrict the flow, forcing the engine to run lean, which leads to poor performance and lower miles per gallon equivalent (MPE) for the generator. Always treat gasoline intended for storage.

Octane Rating and Ethanol

Adhere strictly to the octane rating recommended by the manufacturer. Using a higher octane than necessary does not improve efficiency and is a waste of money. More importantly, minimize the use of fuel with high ethanol content (E15 or E85). Ethanol attracts moisture, causing phase separation and corrosion, which ultimately destroys engine components and significantly impacts fuel efficiency.

The Role of Inverter Technology in Efficiency

If you haven’t yet purchased a generator, or are considering an upgrade, the technology inside the unit makes a profound difference in fuel efficiency.

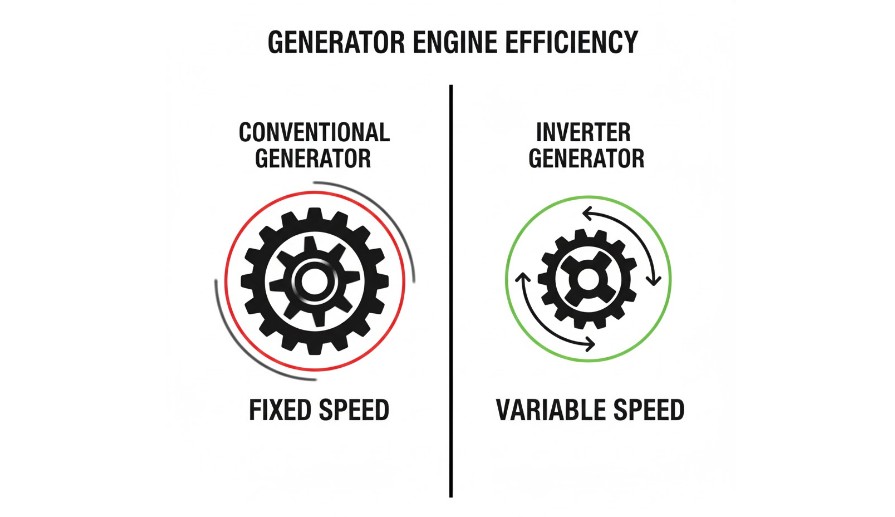

Conventional vs. Inverter Generators

A conventional generator runs its engine at a fixed speed (typically 3,600 RPM) to produce a consistent 60Hz frequency, regardless of the load. If you are only drawing 10% of the maximum capacity, the engine is still running at full speed, resulting in abysmal fuel efficiency.

An inverter generator uses advanced electronics to convert the raw power produced into clean AC power. Crucially, the inverter engine can throttle its speed up or down to match the power demand. If you’re only powering a few lights, the engine will slow down, consuming dramatically less fuel. This inherent ability to match engine speed to load makes dual fuel inverter generators the gold standard for efficiency, often providing 20-40% better fuel economy than their conventional counterparts under partial load.

Maintenance Routines for Peak Efficiency

No matter how well you manage your load or select your fuel, a poorly maintained generator will never achieve maximum fuel efficiency. Think of regular maintenance as a forced efficiency tune-up.

Spark Plugs and Air Filters

A clean air filter is vital. A clogged filter starves the engine of air, leading to a fuel-rich mixture, which means unburnt fuel is wasted—directly reducing efficiency. Similarly, dirty or improperly gapped spark plugs result in weak, inefficient combustion. Replacing or cleaning the spark plugs according to the maintenance schedule ensures a powerful, clean, and *efficient* burn of the fuel.

Oil and Engine Health

Using the correct type and weight of engine oil is paramount. Old, dirty, or incorrect oil creates friction within the engine, causing it to work harder and consume more fuel simply to overcome this internal resistance. Change the oil according to the manufacturer’s specified intervals—often after the first 20-25 hours (the break-in period) and every 50-100 hours thereafter.

The First Start and Load Testing

Every generator, especially a dual fuel generator that may sit for months, benefits from being started and run under load for 20-30 minutes at least once every three months. This circulates oil, prevents seals from drying out, flushes old fuel through the carburetor (if running on gasoline), and verifies all systems are working optimally for the day you need it most. This proactive measure prevents small issues that could significantly drag down fuel efficiency in an emergency.

For those looking at their options, comparing the specifications and features of the best dual fuel generators often highlights models with features that inherently aid in efficiency, such as advanced metering and low oil shut-off.

Advanced Operational Strategies for Long-Term Efficiency

Beyond the mechanical and fuel-specific tips, there are strategic choices that determine overall long-term efficiency and cost-effectiveness.

Sizing Correctly: A Costly Mistake Avoided

Many consumers make the costly mistake of oversizing their generator. An oversized generator will almost always run at a very light load, which, as discussed, is highly inefficient. While having a small buffer is wise, purchasing a 12,000-watt generator for a home that only draws 4,000 watts under load guarantees a lifetime of poor fuel economy. Always perform a proper load calculation before purchase to ensure the unit operates within its 50-75% efficiency window.

The Benefits of Eco Mode and Parallel Operation

For inverter generators, the Eco Mode (or Smart Throttle) is your best friend for efficiency. It automatically limits the engine speed when the electrical load is low, dramatically cutting fuel consumption. Unless you have a specific, high-surge appliance running, Eco Mode should be the default setting. Furthermore, some models allow **parallel operation**, where two smaller, highly efficient generators can be linked to double the power. This approach is more efficient than running a single, large, lightly loaded unit.

Monitoring and Metering

The modern generator often includes an hour meter and, crucially, a power meter (or digital display showing wattage output). Use this information! Constantly monitor the actual power being drawn to ensure you are operating within the 50-75% efficiency zone. This proactive monitoring allows you to make immediate adjustments—switching off a non-essential appliance, for instance—to fine-tune your fuel efficiency.

Final Thoughts

Maximizing Fuel Efficiency in Dual Fuel Generators is not a one-time fix; it is a holistic strategy encompassing correct sizing, meticulous maintenance, informed fuel choices, and disciplined load management. The flexibility of a dual fuel generator is its greatest asset, but that flexibility only translates into real-world savings when you operate it intelligently. By prioritizing the 50-75% load sweet spot, using clean, stabilized fuel, and adhering to a strict maintenance schedule, you can ensure your generator is ready when you need it, and that its precious fuel lasts as long as possible. A dollar saved on fuel is a dollar gained in preparedness.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!