Finding the best angle grinder wheel for cutting metal is a crucial step for any metalworking project, ensuring clean, fast, and safe cuts. Whether you’re a professional welder or a DIY enthusiast, the right cutting wheel is key to getting the job done efficiently and accurately. From durability to cut speed, we break down what makes a cutting wheel stand out.

When it comes to metal fabrication, the performance of your tools can make all the difference. An angle grinder, equipped with the correct disc, is an essential tool for cutting through tough materials like rebar, steel, and iron. However, not all discs are created equal. The most important factors to consider include the abrasive material, thickness, and reinforcement. A quality cutting wheel should offer a balance of aggressive cutting action and long life, allowing you to make more cuts with fewer wheel changes. Additionally, a thin profile is often preferred for fast, burr-free cuts, which ultimately saves you time on cleanup.

Moreover, safety and stability are paramount. Always look for wheels that are reinforced with fiberglass mesh to prevent shattering, which can be a serious hazard. Selecting a disc with a high RPM rating that matches or exceeds your grinder’s speed is also vital for both safety and performance. As you navigate the many options available, consider the specific metals you’ll be working with most often. In this guide, we’ll review some of the top-rated options on the market, helping you find the best angle grinder wheel for cutting metal to meet your project’s demands.

Top 5 Best Angle Grinder Wheel for Cutting Metal

| # | Image | Product Name | $$$ |

|---|---|---|---|

| 1 |  |

DEWALT 4-1/2 Inch Cut-Off Wheel | |

| 2 |  |

SALI 50 Pack Cut Off Wheel | |

| 3 |  |

WORKPRO 20-Pack Cut-Off Wheels | |

| 4 |  |

Merryland Cut Off Wheel | |

| 5 |  |

Benchmark Abrasives 6″ Cutting Wheel |

10 Best Angle Grinder Wheel for Cutting Metal Review

1. DEWALT 4-1/2 Inch Cut-Off Wheel

The DEWALT 4-1/2 Inch Cut-Off Wheel is a fantastic choice for professionals and DIYers alike who need a reliable cutting disc for general purpose metal work. This cutting wheel is engineered with Temper Point grains that deliver a sharp, aggressive cutting action, making it a go-to for tasks on carbon steel, stainless steel, and other nickel-based alloys. Designed for use with an angle grinder, its 50% longer life means you’ll spend less time on replacements and more time on the job. It’s an ideal solution for a variety of projects, from cutting rebar to fabricating pipe, and it is built with the durability you expect from a trusted brand like DEWALT.

In addition to its longevity, this wheel’s thin design and high grain concentration ensure fast, burr-free cuts, minimizing the need for extensive post-cut cleanup. The wheel’s strength is enhanced by two sheets of fiberglass, which significantly reduces the risk of breakage and adds a critical layer of safety during use. While its design is robust, it’s worth noting that the thin profile can make it more susceptible to lateral pressure, so a steady hand is required to maintain a straight cut. Its performance and aggressive action make it a strong contender for anyone seeking a high-efficiency tool, though it may not be the best option for those who are new to using an angle grinder and need a more forgiving disc.

Ultimately, the DEWALT 4-1/2 Inch Cut-Off Wheel excels in its primary function, providing durable and precise cuts. It’s a superb product for anyone needing consistent and reliable performance on a wide range of metals. For a project that demands both speed and precision, this wheel is an excellent investment. The best angle grinder wheel for cutting metal is often one that combines longevity with cutting performance, and this DEWALT disc delivers on both fronts, making it a top recommendation for your toolkit.

| PROS | CONS |

|---|---|

|

|

2. SALI 50 Pack Cut Off Wheel

The SALI 50 Pack Cut Off Wheel is a budget-friendly option for those who need a large quantity of cutting discs for ongoing projects. Designed for fast and aggressive cutting, this wheel is made with a proprietary aluminum oxide grain combination that makes it effective on both metal and stainless steel. Its thin 0.045-inch profile allows for quick, burr-free cuts, which is a major time-saver on the job. Perfectly compatible with all 4-1/2 inch angle grinders with a 7/8-inch arbor, this pack is a practical and economical choice for workshops and avid DIYers who go through a high volume of discs.

Reinforced with a double fiberglass mesh, this cutting disc provides an added layer of safety and durability, preventing premature wear and potential breakage. The aggressive cutting action ensures that you can get through tough materials with minimal effort, which is essential for large-scale projects. However, while the cost per wheel is very low, the durability may not match that of a premium brand’s single wheel. You may find yourself changing discs more frequently on heavy-duty jobs, but the sheer volume of the pack mitigates this drawback significantly. It’s a dependable tool for those who prioritize quantity and value without sacrificing core functionality.

Overall, the SALI 50 Pack is an excellent value proposition, especially for those with a high-volume workload. While it may not offer the same longevity as some higher-priced competitors, its fast cutting action and reinforced design make it a reliable choice. If you’re looking for the best angle grinder wheel for cutting metal in bulk to keep your costs down, this SALI pack is a clear winner. It’s a great choice for both personal projects and professional settings where you need a steady supply of cutting discs. The value is hard to beat.

| PROS | CONS |

|---|---|

|

|

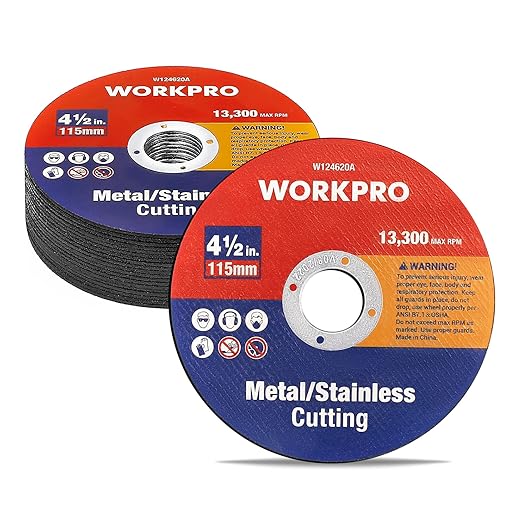

3. WORKPRO 20-Pack Cut-Off Wheels

The WORKPRO 20-Pack Cut-Off Wheels are a reliable and high-value set designed for efficient metal and stainless steel cutting. This set is crafted with a special formulation of corundum and white alundum grain, which provides a more aggressive cutting action and a longer service life. With a 3/64-inch ultra-thin design, these discs deliver precise, burr-free cuts with minimal material loss, making them an excellent choice for detailed and clean work. They are universally compatible with all 4-1/2 inch angle grinders with a 7/8-inch arbor and can handle speeds up to 13,000 RPM, ensuring great performance across a range of tools.

Reinforced with a double fiberglass mesh, the WORKPRO discs are built with safety and durability in mind. This reinforcement helps prevent the wheels from shattering under pressure, giving you peace of mind during demanding cutting tasks. While these wheels are highly versatile for various ferrous metals, some users may find that the ultra-thin design requires careful handling to avoid bending or snapping the disc, particularly on thicker or more stubborn materials. Nevertheless, the precision and clean finish they provide are a significant advantage for projects that require a professional-quality outcome.

The WORKPRO 20-pack provides a strong balance of quality and quantity, making it a great option for those who need a dependable supply of cutting wheels for both small and large jobs. It’s a fantastic value for the performance you get, and a strong contender for the title of best angle grinder wheel for cutting metal. The discs are tough, efficient, and versatile, making them a solid addition to any metalworker’s arsenal. They are particularly well-suited for projects involving a mix of materials where a clean cut is a priority.

| PROS | CONS |

|---|---|

|

|

4. Merryland Cut Off Wheel 4 1/2 inch for Angle Grinder

The Merryland 4-1/2 inch Cut Off Wheel offers a combination of long life and stable performance, making it a reliable tool for metalworking enthusiasts. Crafted from German Phenolic Resin, Refined Calcined, and White Corundum, this cutting disc provides a high-quality cutting experience with a focus on durability. Its ultra-thin 0.045-inch profile ensures fast and accurate cuts with minimal material waste. This disc is particularly versatile, suitable for cutting a wide range of materials including metal, iron, stainless steel (INOX), and even some plastics. For anyone who works with a variety of materials, this disc offers a solid all-around performance.

Safety is a priority with this Merryland disc, as it is built with two layers of reinforced fiberglass mesh to guarantee a secure and stable operation. It meets the European Standard EN 12413 and is MPA Certified, which provides an extra layer of confidence in its quality and safety. While its German-engineered materials are designed for longevity, some users may find that on extremely hard or thick metals, it can wear down more quickly than a specialized, heavy-duty disc. However, for general-purpose use, the balance of speed, precision, and durability is impressive. The disc’s fast cutting action is ideal for both professionals and hobbyists looking to get the job done efficiently.

Ultimately, the Merryland Cut Off Wheel is a solid choice for those seeking a dependable, safe, and versatile cutting solution. It’s an ideal tool for anyone who loves metal working and needs a handy, reliable disc. The consistent performance and commitment to safety make it a strong candidate for the best angle grinder wheel for cutting metal. It’s a smart investment that will provide a high-quality cut on a variety of projects, from sheet metal to steel pipe.

| PROS | CONS |

|---|---|

|

|

5. Benchmark Abrasives 6″ Aluminum Oxide Type 1 Cutting Wheel

The Benchmark Abrasives 6″ Aluminum Oxide Cutting Wheel is a professional-grade option designed for industrial and heavy-duty applications. Engineered with premium aluminum oxide, this Type 1 cutting wheel delivers a powerful and precise cut on a variety of metals, including stainless steel, aluminum, pipes, and tubes. Its .045-inch thickness and 7/8-inch arbor size make it compatible with all major brand angle grinders, offering excellent versatility for both professional fabricators and serious DIYers. With a maximum RPM of 11,000, it provides superior performance for precise, burr-free cuts.

This disc is built for durability and safety, exceeding both ANSI and EU safety standards. The industrial-strength construction ensures reliable performance for demanding projects like shipbuilding and rail work. The .045-inch thin profile allows for fast cutting, reducing heat buildup and minimizing material distortion. However, it’s important to note that a 6-inch disc is not a standard size for all angle grinders, so users must ensure their tool is compatible before purchase. For those with a compatible grinder, this wheel offers consistent cutting quality and long life, which is essential for extensive projects. Its professional-grade design means it’s a bit more of an investment than some other options, but the performance and longevity justify the cost.

For large-scale, professional metalworking, the Benchmark Abrasives 6″ Cutting Wheel is a top choice. It provides the robust performance and consistent quality needed for challenging applications. While the larger size may not be for every user, for those with the right tools, this is an undeniable option for the best angle grinder wheel for cutting metal. Its ability to provide clean, burr-free cuts on a variety of materials makes it an indispensable tool for serious fabricators.

| PROS | CONS |

|---|---|

|

|

6. EZARC Diamond Cutting Wheel 4 1/2 x 7/8 Inch for Metal

The EZARC Diamond Cutting Wheel is a game-changer for anyone tired of constantly replacing bonded abrasive discs. This wheel utilizes advanced diamond technology, allowing it to deliver over 5,000 cuts—an incredible 100 times the life of a standard bonded wheel. It’s a versatile solution for a wide range of metals, including rebar, steel, iron, and stainless steel (INOX), making it an all-in-one tool for professional metalworking. With its solid steel wheel body, this wheel significantly reduces the risk of shattering and injury, providing enhanced safety and boosting productivity by minimizing downtime.

Beyond its impressive longevity and safety features, the EZARC diamond wheel also stands out for its cutting precision. Unlike bonded abrasives that shrink as they wear, this solid disc maintains its original wheel diameter throughout its life. This ensures better control and consistent cutting depth, which is vital for high-precision jobs. A potential drawback is the initial cost, which is higher than a typical bonded disc. However, when you consider its exceptional longevity and the money saved on replacements, the long-term value is undeniable. Furthermore, since it does not wear down like bonded abrasives, it produces fewer dust particles, contributing to a cleaner, safer work environment.

For those who prioritize longevity, safety, and precision, the EZARC Diamond Cutting Wheel is a worthwhile investment. Its ability to provide consistent performance over an extended period makes it one of the top contenders for the best angle grinder wheel for cutting metal. While the upfront cost is higher, the sheer number of cuts you get makes it incredibly cost-effective in the long run. It is an ideal tool for professional settings where durability and safety are non-negotiable.

| PROS | CONS |

|---|---|

|

|

7. 50 Pack Cut Off Wheels 4 1/2 inch for Angle Grinder

This 50-pack of panlen cut-off wheels is designed for professionals and hobbyists who need a reliable and cost-effective solution for metal cutting. The discs are made with a proprietary aluminum oxide grain that ensures both long life and fast, aggressive cutting action. With a skinny 0.045-inch profile, these wheels deliver quick and clean cuts with minimal burring, which saves valuable time on post-cutting cleanup. They are perfectly optimized for 4.5″ angle grinders and can operate at high speeds up to 13,300 RPM, making them a versatile and efficient choice for a wide variety of tasks.

Safety and durability are reinforced with a double fiberglass mesh, which provides additional strength and helps prevent the wheels from breaking under load. These discs are tough and versatile, capable of making super-fast and clean cuts on a range of ferrous metals, including carbon steel, stainless steel, pipe, and cast iron. While the value per disc is excellent, some users might find that they don’t last quite as long as premium, single-purchase discs. However, the large quantity in the pack means you’ll have a constant supply on hand, making it a great option for high-volume jobs or for those who don’t want to run out in the middle of a project.

Overall, this 50-pack is a smart choice for anyone seeking a blend of performance and affordability. It’s a solid contender for the best angle grinder wheel for cutting metal when budget and quantity are key considerations. The dependable performance on various metals combined with the large pack size makes this an ideal product for workshops, fabrication shops, or even a busy home garage. It delivers consistent results and is a reliable staple for any serious metalworker’s inventory.

| PROS | CONS |

|---|---|

|

|

8. BHA Metal and Stainless Steel Thin Cut Off Wheels for Angle Grinders

The BHA Metal and Stainless Steel Thin Cut Off Wheels are a premium, high-performance option for those needing superior cutting power. This 25-pack of 6” x .045” wheels is designed for professional use, offering an ultra-thin design that ensures minimal material loss and a clean, precise cut every time. Made with a proprietary aluminum oxide grain, these discs provide an aggressive cutting action that makes quick work of various metals. They are an excellent choice for a wide range of applications, from general metal cutting to more specific jobs on stainless steel. Their high-quality construction is built to handle demanding tasks and provide reliable results.

The thin profile of these BHA discs is a major advantage, allowing them to slice through materials with less friction and heat buildup, which can prolong the life of both the disc and the workpiece. The aggressive aluminum oxide grain ensures a fast cut without compromising on the quality of the finish. However, as with other 6-inch wheels, it’s essential to ensure your angle grinder is compatible with this larger size. Additionally, their thin design, while great for speed, means they are not intended for grinding or lateral pressure, which could cause breakage. These discs are for cutting applications only, a distinction that is crucial for safety and performance.

For those with a compatible grinder and a need for high-performance cutting, the BHA wheels are a fantastic choice. The 25-pack provides a great balance of quantity and quality for ongoing projects, making it a valuable investment for any workshop. They are a strong contender for the best angle grinder wheel for cutting metal, especially for users who require precision and speed. The high-performance design and aggressive cutting action make them a go-to tool for professionals.

| PROS | CONS |

|---|---|

|

|

9. DeWalt DW8062 4-1/2″x.045″x7/8″ Metal Angle Grinder Thin Cutoff Wheel

The DEWALT DW8062 Metal Angle Grinder Thin Cutoff Wheel is a reliable choice for professional metalworkers and DIY enthusiasts who demand quality and performance. This 10-pack of discs is designed for fast, burr-free cutting, thanks to its thin .045-inch profile. It features a proprietary aluminum oxide grain combination, providing a highly aggressive cutting action that makes quick work of metal. With two full sheets of fiberglass reinforcement, this wheel is built for exceptional durability and safety, reducing the risk of shattering and ensuring a long service life. Its robust design ensures it can handle demanding applications with ease.

One of the key advantages of this DEWALT wheel is its fast and clean cutting performance, which minimizes the need for extra finishing work. The high-quality material mix ensures a durable disc that can withstand heavy use without premature wear. While it excels in its cutting performance, some users might find that the thin design requires a bit more care to prevent the disc from flexing or binding, especially when cutting through thick or uneven materials. However, for a user with a steady hand, this is a minor issue that is far outweighed by the disc’s efficiency and longevity.

Overall, the DEWALT DW8062 is a top-tier choice that delivers consistent, high-quality results. It’s a great product that lives up to the DEWALT brand reputation for reliability and durability. For a user who is looking for a dependable and durable product, this is a strong contender for the best angle grinder wheel for cutting metal. The balance of performance, safety, and durability makes it an excellent choice for a wide variety of tasks, from professional fabrication to home improvement projects.

| PROS | CONS |

|---|---|

|

|

10. LENOX Tools Cutting Wheel, Diamond Edge, 4-1/2-Inch

The LENOX Tools Diamond Edge Cutting Wheel is designed for those who want to get the most life out of a single disc. Thanks to its advanced diamond technology, this wheel can deliver 1,000 or more cuts, providing an impressive 30 times longer life than a standard bonded cut-off wheel. This makes it an incredibly cost-effective option over the long term, reducing the need for frequent replacements and minimizing downtime. It features a solid steel wheel body that greatly reduces the risk of breakage and enhances safety, a major advantage over traditional abrasive discs that can shatter under stress.

One of the unique benefits of this wheel is that it maintains its original diameter throughout its entire life. This feature ensures better control, reach, and precision, which is a significant improvement over bonded wheels that shrink as they wear down. Furthermore, because it doesn’t wear down like abrasive discs, it produces fewer dust particles, contributing to a cleaner and healthier work environment. While the initial cost is higher than a standard abrasive wheel, the long-term savings and enhanced safety features make it a smart investment. It is not designed for aggressive grinding, but rather for clean, precise cuts on a variety of ferrous metals, including carbon steel.

For professional metalworkers and serious DIYers looking for a durable, safe, and long-lasting cutting solution, the LENOX Diamond Edge wheel is an excellent choice. It is a powerful contender for the best angle grinder wheel for cutting metal when durability and cost-per-cut are paramount. The reliability and consistency it offers on every cut make it a standout product in the market. This is a tool that will not only improve your workflow but also provide a safer cutting experience.

How to Choose Best Angle Grinder Wheel for Cutting Metal

When selecting the best angle grinder wheel for cutting metal, it’s important to understand what a grinding wheel is and its purpose. A grinding wheel is an abrasive composite disc used in grinding and cutting operations, primarily for removing material from a workpiece. They are essential tools for metal fabrication, auto body work, and general construction. Choosing the right wheel for your project is crucial as it affects both the speed and quality of your cuts. A great cutting wheel can make a difficult task feel effortless, while the wrong one can be frustrating and even dangerous.

Abrasive Material

The abrasive material is the core component that does the cutting. Most metal cutting wheels are made from aluminum oxide, which is a tough and versatile material suitable for a wide range of ferrous metals like steel and iron. For more demanding tasks, diamond-infused wheels offer exceptional longevity and a clean, precise cut. Diamond wheels are significantly more expensive but can last up to 100 times longer than their bonded counterparts, making them a wise long-term investment.

Wheel Thickness

Wheel thickness is a critical factor for cutting performance. For general-purpose cutting, a thin profile—typically around 0.045 inches (or 1mm)—is ideal. A thin wheel reduces the amount of material being removed, which translates to a faster, cleaner, and more efficient cut with less burring. Thicker wheels (e.g., 1/8 inch) are better suited for light grinding or when a more robust disc is needed to prevent flexing on uneven or heavy-duty materials.

Reinforcement and Safety

Safety should always be your top priority. Look for cutting wheels that are reinforced with double fiberglass mesh. This reinforcement adds structural integrity to the wheel and is a crucial safety feature that prevents the disc from shattering under pressure or if it binds during a cut. Always ensure the maximum RPM rating of the wheel is equal to or greater than the maximum RPM of your angle grinder. Using a disc with an insufficient RPM rating can lead to catastrophic failure.

Diameter and Arbor Size

The diameter of the cutting wheel must match your angle grinder. The most common sizes are 4-1/2 inches, but 5-inch, 6-inch, and 7-inch options are also available. Using a larger wheel on a smaller grinder is dangerous and can lead to a serious accident. Similarly, ensure the arbor hole—the central hole on the disc—is the correct size for your grinder’s spindle. Most standard angle grinders use a 7/8-inch arbor hole.

Cost vs. Longevity

While it can be tempting to buy the cheapest bulk pack of wheels, consider the cost per cut. A premium bonded wheel or a diamond wheel may have a higher initial cost but can last much longer, reducing the number of wheels you need to buy and the time you spend changing them. For frequent, professional use, a durable, long-lasting wheel is often more economical in the long run. Assess your project needs and budget to find the right balance of price and performance.

Maintaining Your Angle Grinder and Cutting Wheels

Proper maintenance of your tools is essential for safety and optimal performance. After each use, clean your angle grinder to remove metal dust and debris, which can clog the motor’s vents and cause it to overheat. Always store your cutting wheels in a cool, dry place to prevent moisture absorption, which can weaken the bonding material and lead to premature failure. Regularly inspect your wheels for cracks, chips, or damage before each use. If a wheel is damaged in any way, discard it immediately. Never use a damaged wheel.

Another critical practice is to use a light, consistent pressure while cutting. Let the speed of the grinder and the abrasiveness of the wheel do the work. Applying too much pressure can cause the wheel to overheat and bind, which is a major cause of breakage. Finally, ensure your grinder’s guard is always in place and correctly positioned to protect you from sparks and debris. Following these simple steps will extend the life of your tools and ensure a safer working environment.

How to Use Best Angle Grinder Wheel for Cutting Metal

The best angle grinder wheel for cutting metal is useless without proper technique. Follow these steps for safe and efficient operation.

- Setup & Prep: Always wear proper Personal Protective Equipment (PPE), including a face shield, safety glasses, gloves, and thick clothing. Secure your workpiece to a stable surface with clamps or a vice. Ensure the cutting wheel is correctly installed on your angle grinder and the guard is in the proper position.

- Core Usage & Best Practices: Start your angle grinder and allow it to reach full speed before making contact with the metal. Use a steady, consistent motion, applying light pressure to let the wheel do the cutting. Do not force the cut. Use a smooth, continuous movement along your desired cut line.

- Optimization & Safety: Avoid twisting or bending the wheel during the cut, as this can cause it to bind and shatter. Keep a clear line of sight, but never look directly at the sparks. When the cut is complete, lift the grinder from the material before releasing the trigger.

- Troubleshooting & Pro Tips: If your wheel is wearing down too quickly, you may be applying too much pressure. If the wheel is not cutting cleanly, it may be the wrong type for the material. For complex cuts, consider marking your line with a scribe and taking a shallow pass first to create a guide.

Frequently Asked Questions

[Question 1 about Best Angle Grinder Wheel for Cutting Metal]

The best angle grinder for welding and other tasks needs the proper wheel. A grinding wheel is thick and designed to grind away material, smooth welds, and sharpen tools, while a cutting wheel is thin and specifically designed to slice through metal. Using a thin cutting wheel for grinding can cause it to shatter, which is extremely dangerous. Always use the right wheel for the job.

How long does a typical cutting wheel last?

The lifespan of a cutting wheel varies greatly depending on the material you’re cutting, the thickness, and your technique. A standard bonded abrasive wheel may last for a few dozen cuts, while a diamond-infused wheel can last for thousands, offering much better longevity and a lower cost per cut.

Can I use a metal cutting wheel to cut other materials like stone or concrete?

No. Using a metal cutting wheel on stone or concrete will quickly destroy the disc and can cause it to overheat and shatter. Always use a specialized diamond or abrasive blade designed specifically for masonry and stone. These blades have a different composition tailored to the hardness and density of stone.

Why are thin cutting wheels better for cutting?

Thin cutting wheels are more efficient because they remove less material (known as the kerf). This reduces friction and heat buildup, allowing the wheel to cut faster and more smoothly with less effort. This results in a cleaner cut with minimal burr, saving you time on finishing work.

What RPM rating should I look for in a cutting wheel?

Always choose a cutting wheel with a maximum RPM rating that is equal to or higher than the maximum RPM of your angle grinder. This is a critical safety consideration. Operating a disc at speeds higher than its rated capacity can cause it to fly apart, which is a serious hazard. Always check the label on both your tool and the disc.

Final Thoughts

Choosing the best angle grinder wheel for cutting metal is a decision that impacts not only the quality of your work but also your safety. By considering factors like the abrasive material, thickness, and reinforcement, you can make an informed choice that will serve you well. A high-quality wheel will provide faster, cleaner cuts and last longer, ultimately saving you time and money. Always prioritize safety and ensure your tools are in good condition. The right wheel is an investment that pays off in both performance and peace of mind.

For most buyers, the SALI 50 Pack Cut Off Wheel offers the best balance of performance and value, providing a high quantity of reliable discs at an economical price. If you need exceptional longevity and safety, choose the LENOX Tools Diamond Edge Cutting Wheel for its durability and solid-body design, which will provide a cleaner and safer cutting experience for years to come.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!