Welding is a trade that requires precision, skill, and an unwavering commitment to safety. For centuries, the process has been defined by the brilliant, intense arc that fuses metal, and the heavy-duty helmet that protects the welder’s eyes and face from it. However, the modern welder’s job is about more than just striking an arc. It’s a comprehensive process that often involves cutting, grinding, and cleaning the workpiece before and after the weld is made. These tasks, while not as visually intense as welding, come with their own set of dangers, including flying sparks, metal shards, and abrasive dust.

In the past, this meant constantly switching between a dark-lensed welding helmet and a clear face shield or safety glasses. This constant change was not only time-consuming but also introduced moments of vulnerability. Fortunately, modern welding helmet technology has provided a revolutionary solution to this problem: grind mode. If you’ve ever seen a welder use their helmet while grinding and wondered, what is grind mode on a welding helmet?, this comprehensive article is your definitive guide. We will delve into its functionality, explore its practical benefits, and explain why it has become an essential feature for welders everywhere.

Beyond the Arc: The Welder’s Workflow

To fully appreciate the value of grind mode, it helps to understand the typical workflow of a professional welder. The process rarely begins and ends with the weld itself. First, the welder must prepare the metal, which often involves cutting it to size and then grinding the edges to ensure a clean, strong joint. Then, the actual welding takes place, requiring a dark, protective lens. Finally, the welder must clean up the finished weld, which can include chipping away slag or grinding down excess material. In the past, this meant wearing safety glasses, putting on a face shield for grinding, taking the face shield off, putting on a welding helmet, and then repeating the process in reverse. This continuous cycle was inefficient and tedious. More importantly, it increased the chances of a welder becoming lax with their safety, perhaps skipping the face shield for a “quick” grind, which could lead to serious injury. This is where the innovation of grind mode became a true game-changer, seamlessly integrating two essential safety functions into one piece of equipment.

So, What is Grind Mode on a Welding Helmet?

Simply put, grind mode is a feature on an auto-darkening welding helmet that locks the lens in its light state, preventing it from darkening when it detects a bright light source. When activated, the helmet’s auto-darkening circuitry is temporarily deactivated. The lens remains in a clear, transparent state, typically with a shade of DIN 3 or 4, which is the same as a pair of safety glasses. This allows the welder to use the helmet for tasks like grinding, cutting, or even a pre-weld visual inspection without having to remove it. It is a brilliant example of a single tool being designed to meet multiple, distinct needs within a single, continuous workflow. This seamless functionality is a direct evolution of the core technology that allows these helmets to darken in the first place, which you can learn more about in our guide on how auto-darkening welding helmets work. The core principle remains the same: the helmet uses its advanced electronics to respond to its environment, but in this case, the welder dictates the response rather than the arc.

How Grind Mode Works and How to Activate It

Activating grind mode is a straightforward process, though the method can vary between helmet models. The most common methods include:

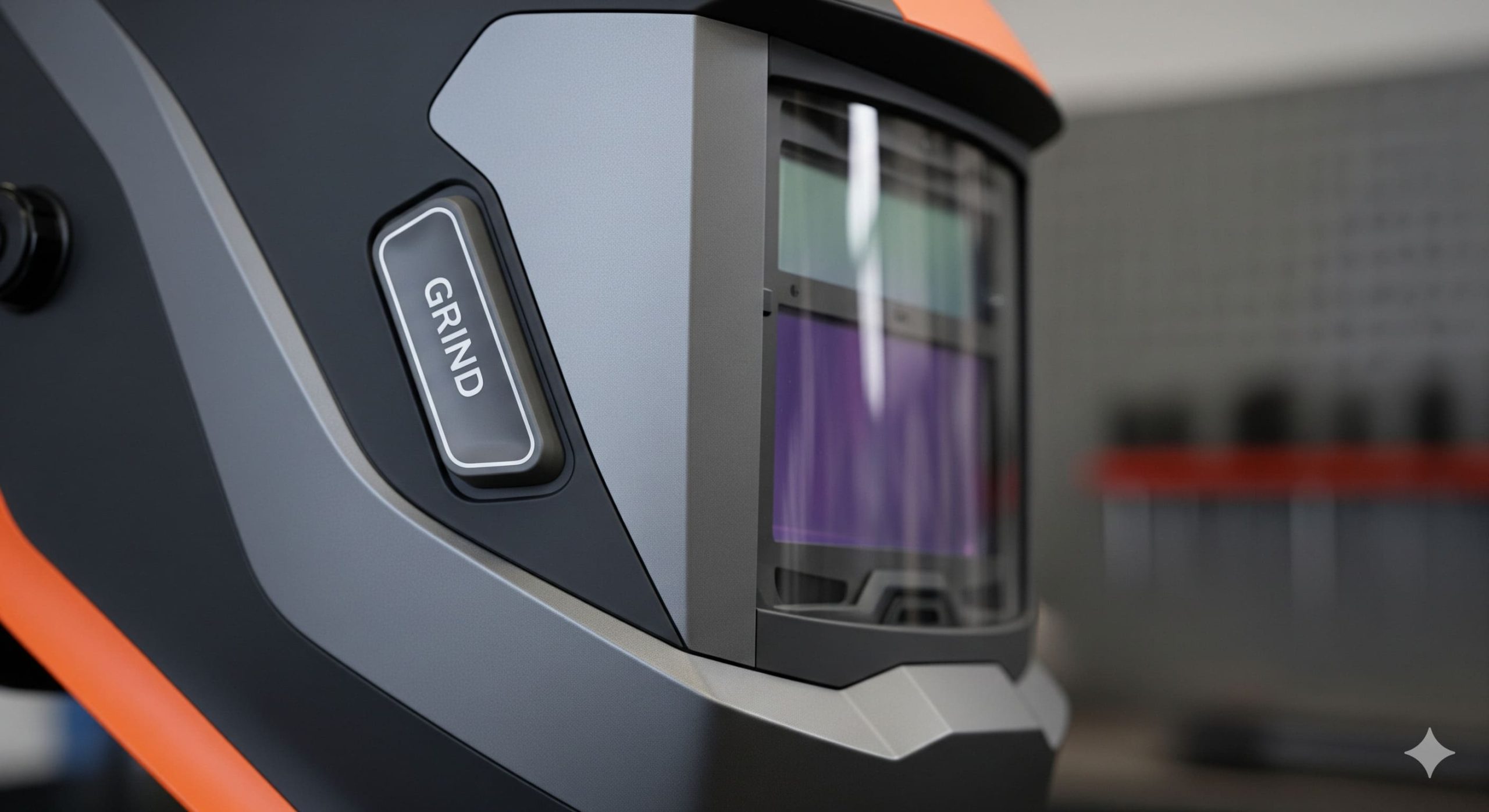

- External Button: Many modern helmets feature a dedicated, easy-to-access button on the outside of the helmet shell. A single press activates the mode, and another press or a set time limit deactivates it. This is the most convenient method as it can be done without removing gloves or the helmet.

- Internal Switch: Some helmets have a small switch located on the inside of the helmet’s headgear, near the controls for shade and sensitivity. This is slightly less convenient but provides a more secure way to lock the helmet in grind mode, as it’s less likely to be accidentally activated.

- Automatic Timer: Some advanced helmets have a mode that automatically switches the helmet back to weld mode after a set period of inactivity, ensuring that the welder is always protected when they return to welding.

Once activated, the helmet’s light sensors are disabled, and the lens remains in its light shade. The welder can then comfortably use an angle grinder, wire brush, or other tools to prepare or clean the workpiece, all while their face and eyes are fully shielded from flying debris. When the task is complete, they simply deactivate the mode, and the helmet is ready to sense an arc and provide its full, dark-shade protection again. This fluid transition between tasks is a key component of a more efficient and safer working environment.

The Practical Benefits of Grind Mode: Why It’s a Game-Changer

The addition of grind mode is not just a clever gimmick; it represents a significant leap forward in welder safety and productivity. The benefits it provides are tangible and directly impact a welder’s daily life on the shop floor.

Enhanced Safety and Protection

Grinding, cutting, and chipping can be just as dangerous as welding. Sparks, abrasive dust, and high-speed metal particles can cause severe eye injuries. While a separate face shield offers protection, a welder’s helmet with grind mode provides a higher level of continuous safety. By eliminating the need to change gear, it ensures that a welder is never unprotected during the various stages of a project. It reduces the likelihood of a welder making a dangerous choice to do a “quick” grind without any face shield, simply because they don’t want to go through the hassle of changing equipment. The helmet’s full-face coverage also protects the welder from flying debris from all angles, a crucial component of overall safety. For more information on eye and face protection standards, you can read about the ANSI/ISEA Z87.1 standard, which covers a wide range of protective gear, including face shields and safety glasses.

Increased Productivity and Efficiency

Time is money, and in a professional welding environment, every minute counts. The simple act of removing a welding helmet, finding and putting on a face shield, and then reversing the process multiple times a day adds up to a significant amount of lost time. Grind mode streamlines this workflow, allowing the welder to move from welding to grinding and back again with a simple press of a button. This seamless transition reduces downtime and allows the welder to maintain focus on the task at hand, leading to higher quality work and greater overall productivity. Furthermore, it eliminates the need to carry and keep track of a separate face shield, which is a major advantage for mobile welders who work out of a truck or in tight spaces where every piece of equipment matters.

Reduced Wear and Tear

Using your primary welding helmet for grinding also helps to preserve other pieces of equipment. Instead of a separate, dedicated face shield that can get scratched or damaged, the helmet’s sacrificial outer lens takes the brunt of the flying sparks and debris. This outer lens is inexpensive and easy to replace, protecting the more expensive auto-darkening cartridge underneath. By using a single piece of equipment for multiple tasks, you reduce the overall wear and tear on your safety gear and ensure that your more specialized tools remain in top condition. For a look at some of the top-rated helmets that offer this and other advanced features, you can check out our guide to the best welding helmets on the market.

Grind Mode vs. Dedicated Grinding Shields

While grind mode is incredibly convenient, some welders still prefer to use a dedicated grinding shield. It’s important to understand the pros and cons of each to make an informed decision for your specific needs.

The Case for the Dedicated Grinding Shield

A dedicated grinding shield is often lighter and more comfortable for long periods of continuous grinding. They typically offer a larger viewing area, which can be an advantage for tasks that require a wide field of vision. Furthermore, they are generally less expensive to replace than a full welding helmet. For a professional who spends a significant portion of their day grinding, a dedicated shield might be a more comfortable and ergonomic choice. In these situations, using a separate grinding shield and a traditional fixed-shade welding helmet is a common practice. For more information on the different options, you can read about the types of welding helmets available on the market, including both passive and auto-darkening models.

The Case for Using Grind Mode

The primary advantage of grind mode is convenience. For welders who perform a lot of small, intermittent grinding tasks, having the functionality built into their helmet is a huge time-saver. It eliminates the need to carry a second piece of gear, which is especially beneficial for mobile welders or those working in confined spaces. Grind mode is perfect for quick spot-grinding before a tack weld or for cleaning up a small weld bead. It’s a tool for seamless transitions, not necessarily a replacement for a dedicated shield on a multi-hour grinding job. Therefore, the decision comes down to the nature of your work. If you primarily weld with only brief moments of grinding in between, a helmet with grind mode is a near-perfect solution. If you’re tackling a project with a full day of grinding, a dedicated shield might be more suitable for comfort and visibility.

Important Safety Considerations and Best Practices

While grind mode is a fantastic feature, it’s crucial to use it correctly to maintain your safety. Here are a few key points to remember:

- Grind Mode is NOT for Welding: This is the most important rule. The lens in grind mode offers no protection against the light and radiation of a welding arc. Always ensure you have switched back to weld mode before striking an arc.

- Check Your Settings: After using grind mode, make it a habit to double-check that your helmet is in weld mode. Some welders even use an audible click or a quick press of the button to confirm the mode has changed before starting to weld.

- Always Wear Safety Glasses: Even with the helmet on in grind mode, it’s a best practice to wear a pair of ANSI Z87.1 certified safety glasses underneath. This provides an additional layer of protection in case of a mechanical failure or an unexpected stray particle finding its way into your helmet.

Final Thoughts

In conclusion, the answer to the question, what is grind mode on a welding helmet? is that it is a powerful, dual-purpose feature that revolutionizes the way a welder works. By allowing the helmet’s auto-darkening lens to stay clear, it provides continuous face and eye protection during non-welding tasks like grinding. This simple but brilliant innovation enhances safety, boosts productivity, and streamlines the workflow for welders of all skill levels.

It eliminates the hassle of constantly swapping equipment and ensures that a welder is protected at all times. Ultimately, a helmet with a high-quality grind mode is more than just a convenience; it’s a testament to the ongoing evolution of safety technology in the welding industry, ensuring that welders can work more efficiently and, most importantly, more safely than ever before. If you are in the market for a new helmet, prioritizing this feature is one of the best decisions you can make for your safety and career.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!