In the vast world of metal fabrication, few techniques command as much respect and admiration as Heliarc welding. A name that might sound like it belongs to a sci-fi movie, it is, in fact, the pioneering predecessor to what we commonly know today as Tungsten Inert Gas (TIG) welding or Gas Tungsten Arc Welding (GTAW). This process is celebrated for its ability to produce exceptionally clean, precise, and high-quality welds, making it an indispensable skill in industries where integrity and aesthetics are paramount. But what exactly is Heliarc welding, and why does its legacy continue to resonate so strongly within the professional welding community?

The Genesis of a Welding Revolution

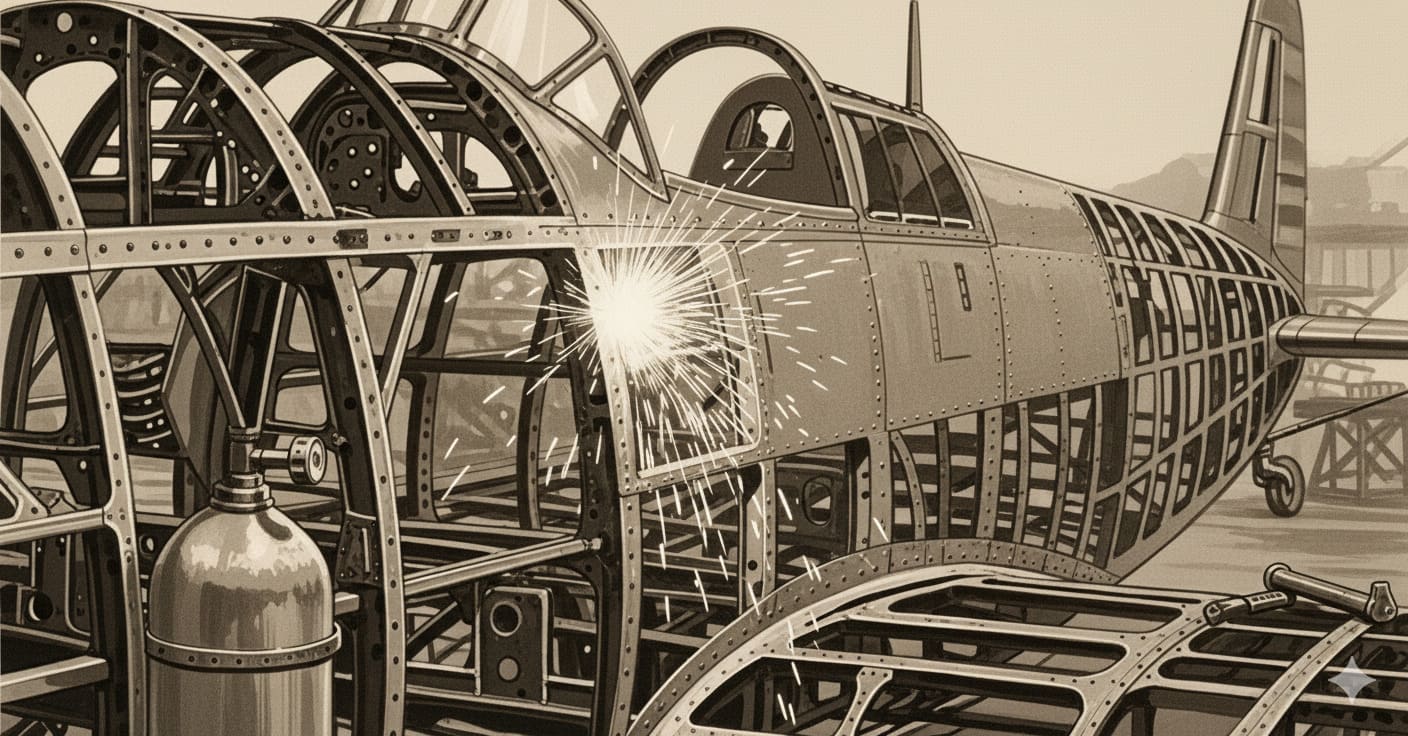

To truly understand what Heliarc welding is, we must journey back to its origins. The early 20th century saw significant advancements in metal joining, but a critical problem persisted: welding reactive metals like aluminum and magnesium. These metals would oxidize rapidly when exposed to the atmosphere during the welding process, resulting in weak, porous, and contaminated welds. Traditional methods simply couldn’t produce the quality needed for the burgeoning aviation industry. This challenge set the stage for a groundbreaking innovation.

A Brief History

The story begins in the late 1930s with engineer Russell Meredith at Northrop Aircraft Corporation. Meredith’s mission was to develop a process that could reliably weld aluminum and magnesium for military aircraft production. His solution was brilliant in its simplicity and effectiveness. He discovered that by using a non-consumable tungsten electrode to create the welding arc and then shielding the weld zone with an inert gas, he could prevent atmospheric contamination entirely. Because he initially used helium as the shielding gas, a name was born: “Heliarc,” a portmanteau of “Helium” and “Arc.” The process was so revolutionary that it caught the attention of President Franklin D. Roosevelt, who reportedly lauded the innovation in a letter to Winston Churchill. This invention was a game-changer during World War II, enabling the rapid and reliable construction of aircraft.

After the war, the patent for the process was acquired by the Linde Division of Union Carbide, which further developed and commercialized the technology. As the process evolved and became more versatile, it began to incorporate other inert gases, most notably argon. The name “Heliarc” became less specific, and the more descriptive names “Tungsten Inert Gas (TIG)” and “Gas Tungsten Arc Welding (GTAW)” became the industry standard. However, many seasoned welders still affectionately use the original term to describe the process, paying homage to its historical significance.

You can learn more about the technical details of the process by visiting the Wikipedia page for Gas Tungsten Arc Welding.

Understanding the Heliarc Process

At its core, Heliarc welding is an arc welding process that uses a non-consumable tungsten electrode to generate heat. Unlike other forms of arc welding, such as MIG or stick welding, the tungsten electrode does not melt and become part of the weld. Instead, it serves solely to create an electric arc between itself and the workpiece, generating the intense heat necessary to melt the base metals.

The Principle of Operation

The process involves three primary components working in harmony: a power source, a non-consumable tungsten electrode, and a supply of inert shielding gas. When the power is turned on, the tungsten electrode creates a highly concentrated arc. This arc melts the edges of the base metals, forming a molten puddle. To add material to the weld joint, the welder manually feeds a separate filler metal rod into the molten puddle with their other hand. This allows for exceptional control over the weld bead’s size and composition. Throughout the entire process, the inert gas—typically argon, helium, or a mixture—flows out of the torch’s nozzle, enveloping the electrode and the weld puddle. This gaseous shield displaces the oxygen, nitrogen, and other reactive elements from the surrounding atmosphere, preventing them from contaminating the weld.

This separation of the heat source (the arc) and the filler material is what gives the welder unparalleled control and is a key reason why Heliarc welding is so celebrated for its precision. It allows for the creation of incredibly clean welds with no spatter or slag, which would otherwise require extensive post-weld cleanup. Furthermore, the use of a foot pedal or a hand-held remote control to adjust the amperage in real-time gives the welder the ability to precisely manage the heat input, a crucial factor when working with thin or delicate materials.

Essential Equipment for Heliarc (TIG) Welding

A successful Heliarc welding setup requires a few key pieces of equipment. While the principles remain the same, modern technology has made the process more accessible and efficient than ever before.

Power Source

The welding machine, or power source, is the heart of the setup. It provides the electrical current needed to create and sustain the arc. Heliarc welding can be performed with both DC (Direct Current) and AC (Alternating Current) machines. DC is commonly used for welding ferrous metals like stainless steel and carbon steel, as well as exotic metals like titanium. AC, on the other hand, is essential for welding aluminum and magnesium. The alternating current’s cleaning action breaks up the oxide layer that forms on these metals, allowing for a strong, clean weld. Modern inverter-based welders are often multi-process machines that can handle both AC and DC, providing incredible versatility. To get started, you might be interested in the best TIG welders for the money.

Tungsten Electrode

The tungsten electrode is the workhorse of the process. It is a non-consumable rod made of pure tungsten or a tungsten alloy. Because tungsten has the highest melting point of any metal (6,192°F or 3,422°C), it can withstand the extreme temperatures of the welding arc without melting. Electrodes come in various compositions, each color-coded for a specific application. For example, thoriated tungsten (red) is a popular choice for DC welding, while zirconiated tungsten (brown) is often used for AC welding on aluminum.

Shielding Gas

As the name implies, the shielding gas is a fundamental component. While the original process relied exclusively on helium, argon is the most widely used gas today. Argon is denser than air, so it forms a stable, consistent shield over the weld puddle. It provides a smooth, stable arc and is suitable for most metals. Helium is a lighter gas that requires a higher flow rate but produces a hotter arc, making it ideal for welding thicker materials or for increasing travel speed. In some cases, a mixture of argon and helium is used to combine the best properties of both gases.

Torch and Other Accessories

The Heliarc torch holds the tungsten electrode and directs the flow of the shielding gas. Torches can be air-cooled or water-cooled; water-cooled torches are necessary for high-amperage applications to prevent overheating. Other accessories include collets to hold the electrode, a nozzle to shape the gas flow, and a foot pedal or finger control to regulate the amperage. The quality of these components directly impacts the quality of the weld. If you’re looking for high-quality components, you might want to read more about the best TIG welding torches on the market.

The Art and Science of Heliarc Welding

While the equipment is essential, the true beauty of Heliarc welding lies in the skill of the welder. The process is often described as an art form because it requires a high degree of manual dexterity and coordination. The welder must use one hand to manipulate the torch, maintaining a consistent arc gap, while the other hand rhythmically feeds the filler rod into the weld puddle. This is a very different experience from MIG welding, where the filler wire is fed automatically.

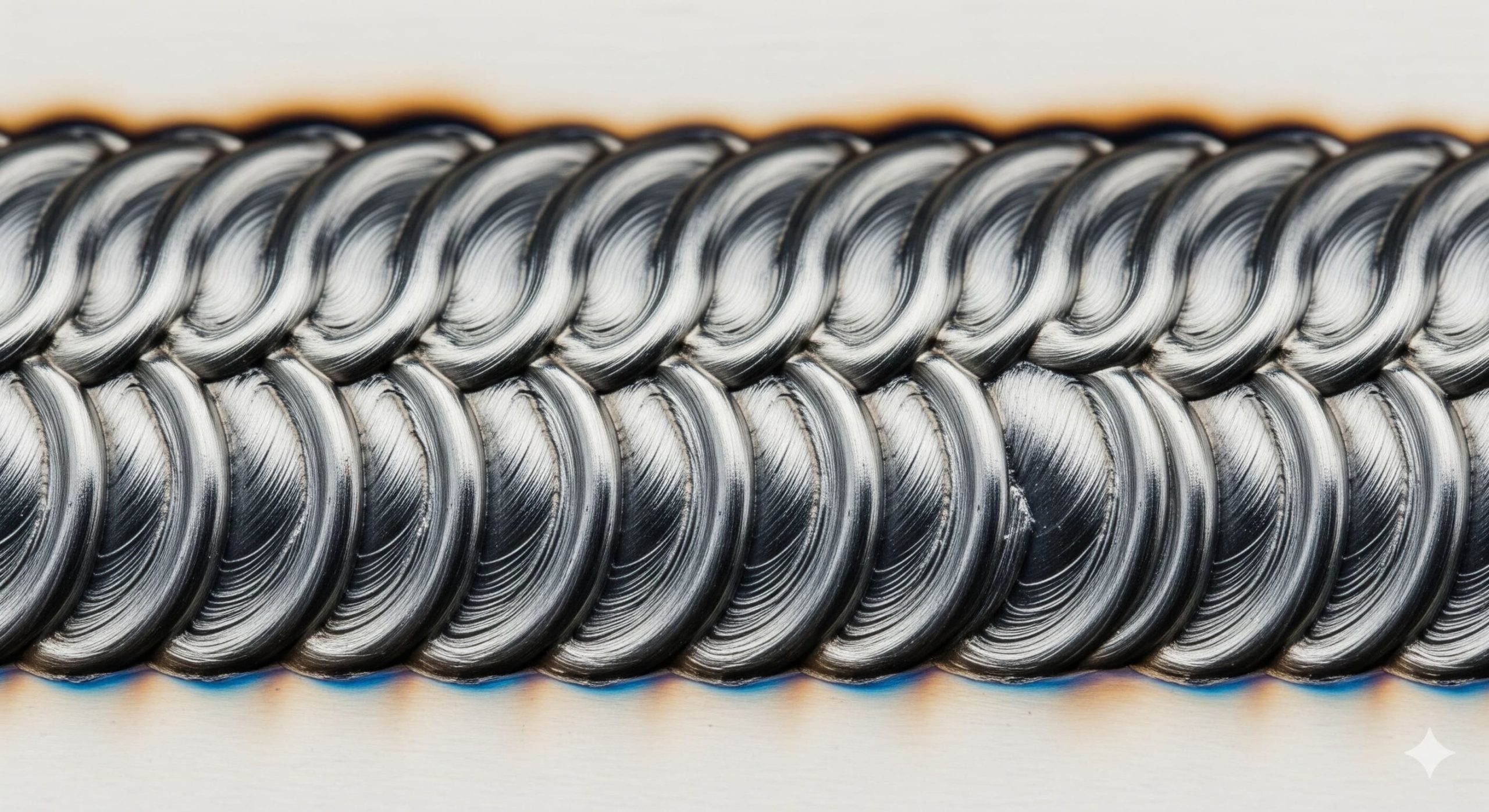

The precise control over heat input, travel speed, and filler metal addition allows for intricate, clean welds that are not only structurally sound but also visually appealing. The characteristic “stack of dimes” appearance of a well-executed Heliarc weld is a hallmark of a skilled professional. This level of control makes it possible to weld incredibly thin materials without burning through them, a feat that is difficult or impossible with other welding processes.

Common Applications and Industries

Because of its precision, cleanliness, and versatility, Heliarc welding is the preferred method for a wide range of applications and industries. Wherever high-quality welds on thin or specialized metals are required, you will likely find Heliarc being used.

Aerospace and Aviation

This is where the process was born, and it remains a cornerstone of the industry. The structural integrity of aircraft components, from airframes to engine parts and fuel tanks, is non-negotiable. Heliarc’s ability to produce strong, clean, and porosity-free welds in materials like aluminum, titanium, and stainless steel makes it the only choice for mission-critical applications where safety is paramount.

Automotive

In the automotive world, Heliarc welding is used for everything from fabricating high-performance exhaust systems and custom chassis to repairing body panels and classic car frames. Its precision is essential for welding thin-gauge metals without warping or deforming them. It’s particularly useful for welding aluminum components, as detailed in our guide on the best TIG welders for aluminum.

Food and Beverage

The food and beverage industry relies on strict hygiene standards. Equipment like stainless steel tanks, pipelines, and processing machinery must be easy to clean and free of crevices where bacteria can grow. Heliarc welding produces smooth, sanitary welds that are corrosion-resistant and meet the stringent requirements of the industry.

Artistic and Custom Fabrication

For artists, sculptors, and custom fabricators, Heliarc welding is a powerful tool for bringing complex designs to life. The ability to create delicate, clean joints without visible spatter makes it ideal for creating intricate metal artwork and custom furniture. It provides a level of control that allows the welder to essentially “draw” with molten metal.

Advantages of Heliarc Welding

The benefits of the Heliarc process are clear and numerous. Here’s a breakdown of why it’s so highly regarded:

- Exceptional Weld Quality: The inert gas shield prevents contamination, resulting in strong, clean, and defect-free welds with no spatter.

- Precision and Control: The separation of the electrode and filler metal, combined with real-time amperage control, allows for unparalleled precision, making it ideal for thin materials and intricate joints.

- Versatility: It can be used to weld a wide variety of metals, including aluminum, magnesium, copper, titanium, and stainless steel.

- No Slag or Flux: The process does not use flux, eliminating the need for post-weld slag removal and cleanup.

- Aesthetically Pleasing Welds: The clean, consistent beads are often a work of art in themselves, making it the top choice for visible welds where appearance is important.

Disadvantages and Challenges

Despite its many advantages, Heliarc welding is not without its challenges. It requires a higher level of skill and can be less efficient for certain applications.

- Complexity: The manual coordination required to operate the torch and filler rod simultaneously makes the process more difficult to learn and master compared to other methods like MIG welding.

- Slower Process: Because it is a more deliberate and precise process, it is significantly slower than MIG or flux-cored arc welding. It is not suitable for high-production, high-speed applications.

- Cost: Heliarc equipment can be more expensive than basic MIG or stick welders, and the cost of argon or helium shielding gas can add up.

- Portability: While modern inverter welders are much more portable, the need for a separate gas cylinder and a more complex setup can limit mobility in certain situations.

Heliarc vs. Other Welding Processes

When comparing Heliarc (TIG) welding to other common methods like MIG and stick welding, the differences become starkly apparent. Stick welding (SMAW) is known for its simplicity and robustness, making it suitable for thick, dirty metals in outdoor conditions. However, it produces significant spatter and slag and is not suited for thin materials. MIG welding (GMAW) is a semi-automatic process that is fast and easy to learn, making it the go-to choice for many production applications. It is less precise than Heliarc, and while it produces less spatter than stick welding, it still requires more cleanup.

The primary differentiator for Heliarc is its focus on quality over speed. It is the gold standard for applications where the integrity of the weld and a flawless finish are the most important factors. For this reason, it is often seen as a specialist’s tool, reserved for the most demanding jobs.

Final Thoughts

The legacy of Heliarc welding is a testament to the power of innovation in the face of a seemingly insurmountable challenge. What began as a solution for a specific problem in aircraft manufacturing evolved into a fundamental process that has shaped countless industries. Though the name may be less common today, its spirit lives on in every clean, strong, and precise TIG weld. It remains a skill that signifies craftsmanship, dedication, and an unwavering commitment to quality. For anyone serious about metal fabrication, understanding and mastering the principles of Heliarc is not just an option—it’s an essential step toward achieving excellence.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!