The name WEN is practically synonymous with affordable, reliable power tools and, increasingly, portable generators. For decades, homeowners, DIY enthusiasts, and professionals have turned to the brand for a blend of performance and value. However, as consumers become more conscious of product origins, a fundamental question often arises: Where are WEN generators made? The answer, as is often the case in today’s global economy, is a nuanced blend of American design and international manufacturing.

This article will take a deep dive into the manufacturing origins of WEN generators, explore the company’s American heritage, discuss the implications of their global supply chain, and ultimately help you understand what this means for the quality and value you receive as a consumer. By understanding the “where” and the “why,” you can make a more informed decision when choosing your next power source.

The Short Answer: Design in America, Manufacturing in China

To cut right to the chase, the manufacturing of WEN generators primarily takes place in facilities in China. This is a common practice across the portable generator industry, where many major brands leverage overseas production to manage costs and scale their operations to meet global demand. However, this fact tells only half the story.

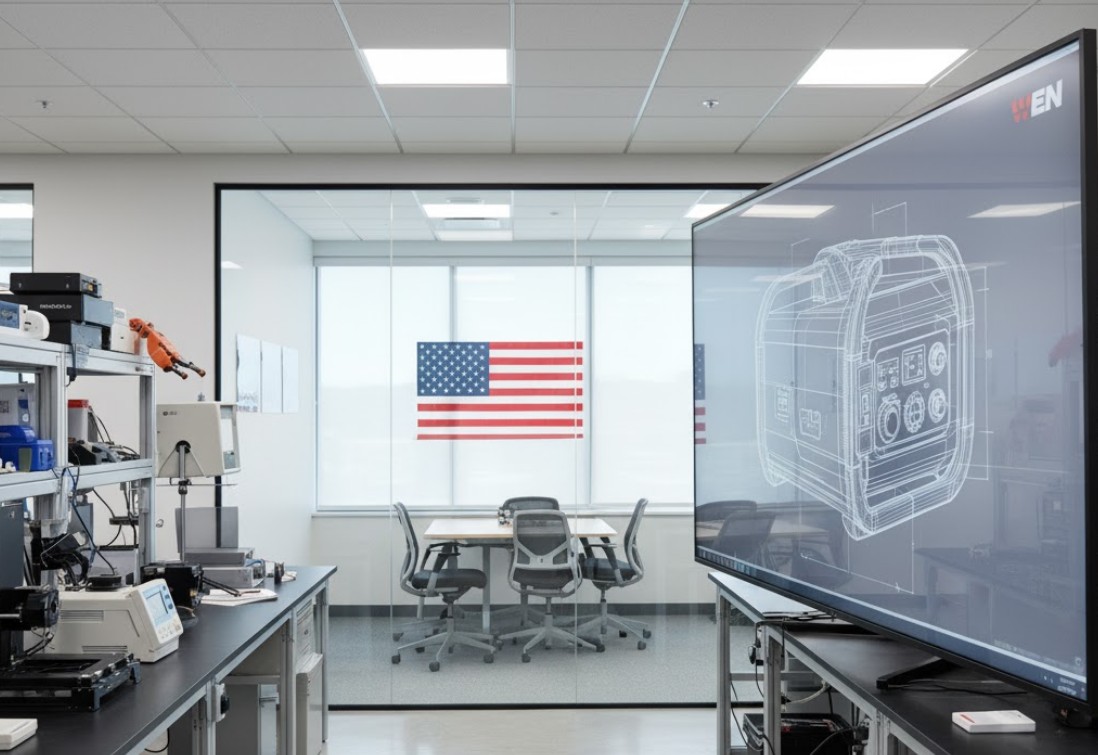

The crucial distinction is that WEN is an American company. WEN Products, officially headquartered in West Dundee, Illinois, is responsible for the company’s research, engineering, design, quality control, and customer service. Therefore, while the final assembly and bulk of the component manufacturing occur overseas, the core innovation and quality assurance standards are set and maintained in the United States. This model is often referred to as “Designed and Engineered in America, Manufactured Overseas.”

WEN Products: An American Legacy Since 1951

The roots of WEN Products are firmly planted in the post-WWII American industrial boom. Founded in 1951 by Nick Anton, the company initially focused on a different kind of power—electric power tools. In fact, WEN is credited with playing a major role in developing and marketing some of the most common tools we use today, including the electric soldering gun, the electric jigsaw, and the electric engraver. They were innovators in putting “the power into power tools.”

Their corporate history is one of continuous evolution, moving from simple power tools to a broad catalog that now includes everything from drill presses and air compressors to their popular line of portable power generators. The company’s headquarters in West Dundee, Illinois, remains the center of its operations, overseeing product development, quality standards, and customer support for all its products, including the line of WEN generators. This historical context is vital, as it highlights that the brand is not a foreign entity but an established American business utilizing a global supply chain.

The Global Supply Chain: Why Manufacturing is Outsourced

The decision to manufacture WEN generators in China is not unique to the brand; it’s a strategic move shared by a vast number of consumer electronics and power equipment manufacturers globally. Several compelling economic and logistical factors drive this choice:

Cost Efficiency and Economies of Scale

The single biggest driver is cost. Manufacturing facilities in China often offer significantly lower labor and overhead costs compared to those in the United States or Europe. Furthermore, the established industrial infrastructure in China allows for incredible economies of scale. When a company like WEN can produce components and assemble units in massive quantities, the per-unit cost drops dramatically. This efficiency allows WEN to maintain its core value proposition: offering reliable generators at a much more competitive price point than many of its rivals. For the consumer, this translates directly to a more affordable purchase, whether they’re looking for a compact inverter or a robust model like those featured on sites discussing the best 3000 watt generators.

Access to a Vast Manufacturing Ecosystem

The Chinese manufacturing sector is not just about low cost; it’s about a complete ecosystem. Over decades, a sprawling network of specialized component suppliers, raw material providers, and advanced assembly factories has developed. This allows WEN to source high-quality parts—from complex engine components to sophisticated inverter technology—quickly and efficiently. In essence, the Chinese supply chain offers a level of vertical integration and scale that is difficult, if not impossible, to replicate cost-effectively elsewhere.

Engine Design and Technology

Interestingly, the engines in many WEN generators are often described as “clones” or highly comparable to the designs of top-tier Japanese engines, particularly those from Yamaha. This similarity isn’t accidental. It reflects the adoption of proven, reliable engine architecture within the manufacturing process, a capability that has been perfected by Chinese manufacturers over many years. This commitment to a trusted design contributes significantly to the reliability that WEN customers appreciate. This focus on proven engine technology is one of the reasons WEN products are consistently rated highly, especially when compared to competitors in categories like the best quietest portable generators, where engine design is paramount.

Maintaining Quality: The American Design and Oversight

A common concern when products are manufactured overseas is the potential for a drop in quality. However, for a successful brand like WEN, whose reputation is built on value, maintaining stringent quality control is non-negotiable. This is where the American-based operation plays its most critical role.

Engineering and Testing

All WEN generator designs originate in the company’s Illinois headquarters. This includes the initial concepts, detailed engineering blueprints, and the selection of core technologies, such as their popular inverter generators. Furthermore, WEN is heavily involved in the testing and prototyping phases. Before a product goes into mass production, it must meet the exacting performance and safety specifications set by the American team. This ensures that a generator, regardless of where it is physically assembled, performs exactly as an American-designed product should.

Supplier Relationships and Audits

WEN does not simply hand over its blueprints and walk away. The company maintains close relationships with its overseas manufacturing partners. They employ dedicated teams to conduct regular audits and inspections of the production facilities. These checks cover everything from component quality and assembly processes to final product testing and packaging. This continuous oversight is essential to guarantee that the mass-produced units maintain the consistency and durability expected by North American consumers.

Customer Support and Warranty

Perhaps the most direct link to the American operation that consumers interact with is the support and warranty service. WEN’s customer service and technical support teams are based in the United States and are known for being responsive and helpful. The availability of replacement parts and a clear warranty process, managed by the American team, offers a layer of assurance that is critical for any power equipment purchase. This is a significant differentiator from smaller, less established brands that may only offer an overseas point of contact.

Implications for the Consumer: Value vs. Origin

Knowing that WEN generators are made in China under American supervision raises an important question: is this a good or a bad thing for the buyer? In reality, it allows WEN to strike a balance that benefits most consumers:

The Value Proposition

The key benefit is unparalleled value. By optimizing the supply chain for cost-effectiveness, WEN can pack desirable features into their generators without the premium price tag. Features like electric start, dual-fuel capability, and parallel connectivity often come standard on WEN models, making advanced generator technology accessible to the average homeowner. Whether you’re preparing for a short blackout or considering more significant options like the best whole house generators, the affordability factor WEN offers in its portable line is a strong selling point.

Quality in the Context of Price

While a WEN generator might not possess the absolute highest-tier fit and finish of a top-end, premium-priced brand, their quality is consistently high relative to their cost. The components are durable, the engines are reliable, and the overall construction is solid. Online reviews and community discussions frequently confirm that WEN offers an excellent return on investment, which is a testament to the effectiveness of their American-managed quality control process.

Understanding the Competition

It’s also important to view WEN’s manufacturing strategy in the context of the larger generator market. The reality is that a significant majority of portable generators sold in North America, including many models from brands considered “American,” utilize an identical or similar manufacturing model. Few companies can afford to produce all components and complete all assembly exclusively in the US and still meet the market’s demand for low prices. WEN is simply transparent about a reality of modern consumer product manufacturing. Before making a purchase, a quick look at the WEN Products official website (https://wenproducts.com/) can provide the latest product details and company statements.

The WEN Generator Lineup: A Focus on Innovation

The manufacturing location has not hindered WEN’s ability to innovate, as their American R&D team continuously pushes for new features and technologies. Their product line demonstrates a clear focus on the needs of modern generator users:

Inverter Generators: Quiet Power

WEN has become one of the most recognizable names in the inverter generator market. Their inverter technology, which produces clean power suitable for sensitive electronics, is a standout feature. Furthermore, they are widely praised for their quiet operation—a necessity for camping, tailgating, or even residential backup. This focus on low noise is a key factor when evaluating generators, as seen in market comparisons of the best quietest portable generators. This is a prime example of American engineering driving a Chinese-built product to meet a specific consumer need.

Dual Fuel Models: Versatility for the User

Another popular innovation is the inclusion of dual fuel capability on many of their portable generators, allowing users to switch between gasoline and propane. Propane offers longer shelf life, cleaner burning, and is often easier to store during long-term power outages, adding a significant layer of versatility that consumers value.

High-Wattage and RV-Ready Options

WEN’s lineup spans a wide range of power outputs, from small, highly portable units perfect for an RV to larger models capable of handling essential home circuits via a transfer switch. The engineering team ensures that even their high-wattage generators maintain a good balance of size, portability, and power, addressing the needs of those seeking serious emergency power.

The Future of WEN and Generator Manufacturing

As the conversation around supply chain resilience and national manufacturing continues to evolve, the global sourcing model of companies like WEN may adapt. While the current setup of American design and Chinese manufacturing is a powerhouse for value, companies are constantly evaluating options.

The trend towards advanced automation and robotics could, in the long term, reduce the cost difference between manufacturing in China and other locations. However, for now, the established infrastructure and scale in Asia provide a substantial advantage. It’s highly likely that WEN generators will continue to follow the current model for the foreseeable future, focusing on optimizing their supply chain and doubling down on their American-led quality control to deliver the best possible product at the most competitive price.

For the generator industry as a whole, WEN’s success demonstrates that a product’s origin is less important than the quality of its engineering and the rigor of its quality control. Consumers are increasingly sophisticated, looking beyond simple country-of-origin labels to assess the real-world value, reliability, and support a brand offers.

Final Thoughts

When you ask, “Where are WEN generators made?” the most accurate and informative answer is that they are the result of a global effort: Designed and Engineered in America by WEN Products, a company with over 70 years of history and a commitment to innovation, and Manufactured in China using efficient, large-scale production facilities. This strategic combination is precisely what allows WEN to dominate the value segment of the generator market.

For the prospective buyer, the takeaway is clear: WEN generators offer an excellent blend of quality, proven technology (often compared favorably to Yamaha designs), and exceptional affordability. The core American management ensures that the products meet the standards and expectations of the North American consumer, providing a reliable and cost-effective power solution for everything from recreational use to home backup. Ultimately, the global supply chain has delivered a winner for the budget-conscious consumer seeking reliable power.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!