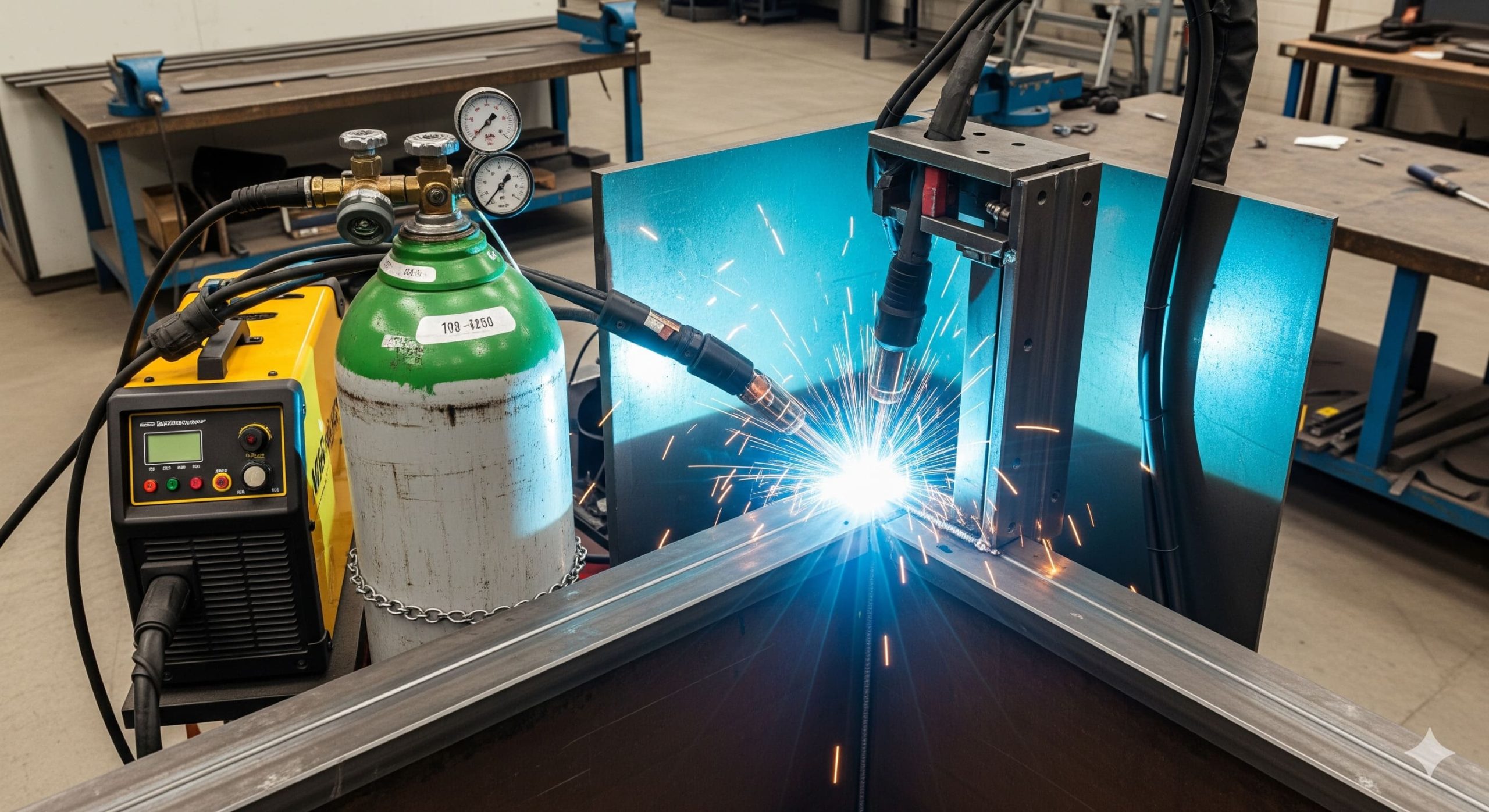

MIG welding, or Gas Metal Arc Welding (GMAW), is a popular and versatile process used by everyone from hobbyists to professional welders. It’s known for its speed, efficiency, and ability to create clean, strong welds on a variety of materials. But to get the most out of your MIG welder, you need more than just the machine and a spool of wire. The shielding gas you choose is arguably one of the most critical components of the entire setup. In fact, selecting the right gas can be the difference between a clean, strong weld and a messy, porous one.

This article will serve as your complete guide to understanding and choosing the best gas for MIG welding. We’ll delve into the different types of gases, their properties, and how they affect the welding process on various metals. We’ll also cover common gas mixtures, their applications, and some key factors to consider when making your choice. By the end, you’ll have the knowledge to select the perfect shielding gas for your next project, ensuring a professional, high-quality result every time.

What is Shielding Gas and Why is it So Important?

Before we explore the different types of gases, let’s first understand their fundamental purpose. In simple terms, a shielding gas is a stream of gas that flows out of the welding gun and surrounds the welding arc and the molten weld pool. This creates a protective bubble that shields the weld from atmospheric contaminants, specifically oxygen and nitrogen.

When hot, molten metal is exposed to the air, it quickly oxidizes and can absorb nitrogen, leading to a weak, brittle, and porous weld. These defects are not only unsightly but can compromise the structural integrity of the finished product. The shielding gas displaces the air, allowing the filler wire and base metal to fuse together without contamination. Furthermore, the type of gas you use also plays a significant role in arc stability, heat input, penetration profile, and the overall look of the finished weld.

If you’re considering a gasless setup, you should know that this process, known as Flux-Cored Arc Welding (FCAW), uses a hollow wire filled with a special flux compound. When the arc heats the wire, the flux burns off and creates its own protective gas shield. While gasless welding is great for outdoor or windy conditions where shielding gas would be blown away, it often results in more spatter and a less-clean weld. For the cleanest, most professional results, especially on thin materials or for projects that require a high-quality finish, gas-shielded MIG welding is the preferred choice.

Types of Shielding Gases: Inert vs. Active

Shielding gases are generally categorized into two main groups: inert and active. Understanding the difference between these two is the first step in selecting the right gas.

Inert Gases

As the name suggests, inert gases do not chemically react with the molten metal. They simply provide a physical barrier to protect the weld pool. The most common inert gases used in MIG welding are:

1. Argon (Ar)

Argon is the most widely used inert gas for MIG welding. It is denser than air, so it effectively blankets the weld pool. Argon produces a stable, smooth arc with low spatter. When used on its own, it’s perfect for welding non-ferrous metals.

Key Characteristics:

- Arc Stability: Excellent and smooth.

- Weld Profile: Narrow and deep, often referred to as a “finger” profile.

- Spatter: Very low.

- Cost: Relatively affordable and widely available.

- Best for: Aluminum, copper, magnesium, and other non-ferrous metals.

Note: While pure argon is fantastic for non-ferrous metals, it is not recommended for welding steel. Its narrow arc and lower heat input tend to create a taller, less-spread-out weld bead, which can lead to lack of fusion and poor penetration on steel.

2. Helium (He)

Helium is another inert gas, but it behaves very differently from argon. It is much lighter than air and has a higher ionization potential, which means it requires more voltage to start and maintain an arc. This results in a much hotter arc and a wider, shallower penetration profile.

Key Characteristics:

- Arc Stability: Less stable than argon, leading to more spatter.

- Weld Profile: Wide and shallow.

- Heat Input: Extremely high.

- Cost: Significantly more expensive than argon.

- Best for: Welding thick materials, especially aluminum and copper, as the high heat helps with proper fusion.

Because of its high cost and tendency to float away quickly, helium is rarely used on its own. Instead, it is commonly blended with argon to combine the benefits of both gases.

Active Gases

Active gases, on the other hand, are chemically reactive and participate in the welding process. They can improve arc stability, change the weld’s mechanical properties, and increase penetration. The most common active gases are:

1. Carbon Dioxide (CO2)

Carbon dioxide (CO2) is the most common and least expensive active gas. It is a very reactive gas that breaks down in the heat of the arc to create oxygen and carbon monoxide, which then react with the molten metal.

Key Characteristics:

- Arc Stability: Less stable than argon, leading to more spatter.

- Weld Profile: Very deep and wide penetration.

- Spatter: High.

- Cost: Very affordable.

- Best for: Welding mild steel, particularly thicker or dirtier materials, as the deep penetration helps to burn out impurities.

Note: Pure CO2 is a very aggressive gas and can only be used on ferrous metals (steel). It will cause severe porosity and a terrible weld on non-ferrous metals like aluminum.

2. Oxygen (O2)

Oxygen is typically used in small percentages (1-5%) as a blend with argon. It’s never used on its own. A small amount of oxygen can significantly improve arc stability and fluidity of the weld pool when welding certain types of steel.

The Most Common Gas Blends for MIG Welding

While pure gases have their uses, the vast majority of MIG welding is done with a mixture of gases. These blends are engineered to provide the perfect balance of arc stability, penetration, and weld appearance for a specific application.

1. Argon/CO2 Blends (e.g., C25)

This is, by far, the most popular and versatile gas blend for MIG welding. The most common mixture is 75% Argon and 25% CO2, often referred to as C25.

Applications:

- Mild Steel: The go-to choice for welding mild steel of all thicknesses.

- Stainless Steel: Some welders use this blend for stainless steel, though other blends are often preferred for a cleaner finish.

Why it’s so good:

The argon component provides a stable, smooth arc with minimal spatter. The addition of CO2 increases the heat input, improves penetration, and widens the weld bead, preventing the “finger” profile common with pure argon. This combination gives you a great balance of a clean weld with deep, reliable penetration. It’s an excellent all-around gas, especially for beginners.

Many MIG welders for beginners are designed to work seamlessly with C25 gas, making it a great starting point for anyone learning the trade.

2. Argon/Oxygen Blends

These blends, typically 98% Argon and 2% Oxygen, are also used for welding steel. The small amount of oxygen improves arc stability and makes the weld pool more fluid, creating a flatter, smoother bead profile.

Applications:

- Stainless Steel: An excellent choice for welding stainless steel, as the oxygen helps to “wet out” the weld, creating a visually appealing finish with minimal discoloration.

- Mild Steel: Can be used for mild steel but generally produces a flatter, more aesthetic bead than C25.

Note: Like CO2, oxygen is a reactive gas and cannot be used for non-ferrous metals like aluminum or copper.

3. Argon/Helium Blends

As mentioned earlier, helium is a great addition for increasing heat input. When blended with argon, it becomes a powerful tool for welding thick or highly conductive metals. Common blends range from 75% Argon/25% Helium to 50% Argon/50% Helium.

Applications:

- Thick Aluminum: The high heat from helium helps achieve proper fusion and penetration on thick aluminum plates.

- Copper and Magnesium: Excellent for these highly conductive metals that require a lot of heat to weld.

For welders focused on aluminum welding, an argon/helium blend can be a game-changer. It overcomes the challenges of a purely argon shield on thicker materials, providing the necessary heat without compromising on the clean weld that argon is known for.

4. Tri-Mix Gases

These specialized blends typically contain Argon, Helium, and a small percentage of CO2. A common example is 90% Helium, 7.5% Argon, and 2.5% CO2.

Applications:

- Stainless Steel: Considered one of the best choices for MIG welding stainless steel, especially for industrial and high-quality applications.

Why it’s so good:

This blend combines the benefits of all three gases. The helium provides the necessary heat for deep penetration, the argon provides arc stability, and the CO2 helps with metal transfer and weld wetting. The result is a high-quality, professional weld on stainless steel with excellent penetration and a clean, smooth finish.

Choosing the Best Gas for Your Specific Project

With so many options, how do you know which one is right for you? It all comes down to a few key factors: the material you’re welding, the thickness of that material, and the desired weld quality.

For Mild Steel

Best Overall: 75% Argon / 25% CO2 (C25). This is the industry standard for a reason. It offers the perfect blend of performance, cost-effectiveness, and versatility for almost all mild steel applications, from thin sheet metal to thicker structural steel. It provides good penetration and a clean, controllable arc with minimal spatter.

Budget Option: 100% CO2. If cost is your primary concern and you’re willing to do more cleanup, pure CO2 is a viable option for mild steel. It provides excellent penetration, especially on thicker or dirty materials, but it will produce a lot of spatter and a less-aesthetic weld. It’s often used for projects where weld appearance is not a major concern.

For Stainless Steel

Best Overall: A Tri-Mix blend (Argon/Helium/CO2). While more expensive, this blend offers the best results for stainless steel, providing deep penetration, excellent arc stability, and a clean, professional finish that resists oxidation.

Common Alternative: 98% Argon / 2% CO2. This mixture is a very popular and effective choice for general stainless steel welding. The low CO2 content provides just enough arc stability and wetting action without significantly impacting the corrosion resistance of the stainless.

For Aluminum

Best for Thin Aluminum: 100% Argon. For most sheet aluminum and general-purpose welding, pure argon is the go-to gas. It provides a clean, stable arc and is essential for the “cathodic cleaning action” that removes the aluminum oxide layer, which is crucial for a strong weld.

Best for Thick Aluminum: Argon/Helium Blends. When welding aluminum plates thicker than 1/2 inch, the added heat from helium is necessary to achieve proper fusion and penetration. The higher the helium content, the hotter the weld and the deeper the penetration.

Flow Rate: Don’t Overlook This Crucial Setting

Once you’ve chosen the right gas, you need to set the correct flow rate. This is the amount of gas, measured in cubic feet per hour (cfh) or liters per minute (lpm), that is flowing through your torch.

The general rule of thumb is a flow rate of 15 to 25 cfh for most indoor applications. Too little flow and you risk atmospheric contamination; too much and you can create a turbulent flow that draws contaminants into the weld, leading to porosity. You should always consult your machine’s manual and the manufacturer’s recommendations for the specific settings.

Final Thoughts

Choosing the right shielding gas is a fundamental part of the MIG welding process. It’s not just an afterthought; it’s a critical component that directly influences the quality, strength, and appearance of your welds. For most general-purpose work on mild steel, a 75% Argon / 25% CO2 blend is the most reliable and effective choice. For aluminum, you can’t go wrong with pure argon. As you advance and take on more specialized projects, you can explore the benefits of tri-mix gases for stainless steel or argon/helium blends for thicker materials.

Ultimately, understanding the properties of each gas and how it interacts with the material you’re welding will empower you to make informed decisions and produce consistent, professional results. So, before you strike an arc on your next project, take a moment to consider your gas choice—it might just be the most important decision you make.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!