The moment a storm hits or the grid fails, your generator is your fortress against darkness. You crank it up, the engine roars to life—a sound of security—but then you realize the outlets are dead. That sinking feeling is instantly replaced by a critical question: Why is my generator not producing power? This problem, frustrating as it is, is often solvable with a systematic approach. Understanding the relationship between the engine, the alternator, and the safety mechanisms is key to pinpointing the failure. This comprehensive, expert-level guide will break down every potential cause, from simple fixes to complex electrical faults, empowering you to restore your power.

The Fundamental Electrical Principle: Generation vs. Excitation

To troubleshoot effectively, we must first understand the two core functions required for electricity generation. The first is mechanical power, provided by the engine. The second is magnetic excitation, managed by the alternator head. If the engine is running, the mechanical part is mostly solved, shifting our focus primarily to the alternator.

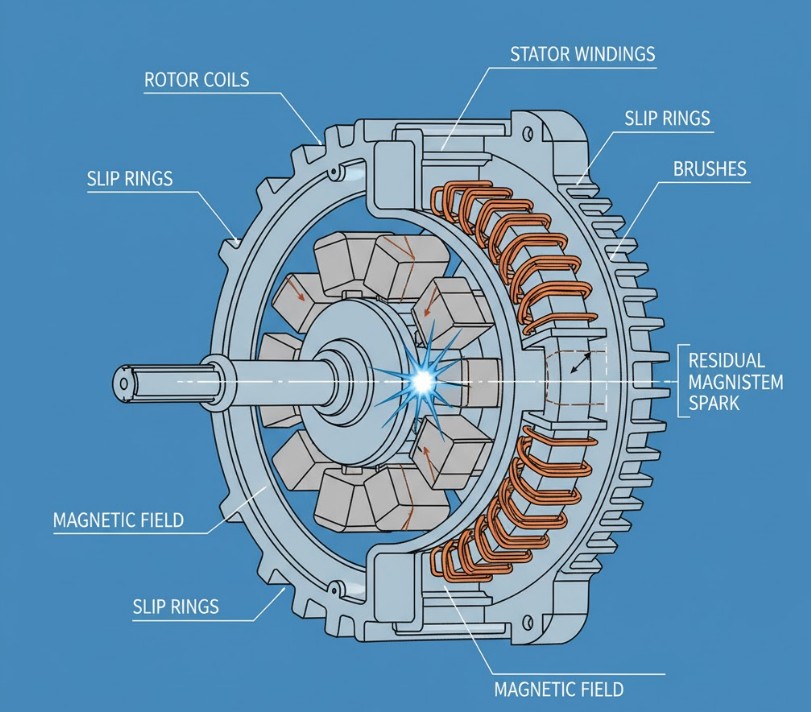

The Critical Role of Residual Magnetism

Every generator, from a small portable unit to a large standby model, requires a small, residual magnetic charge in the rotor’s iron core to initiate power production. Think of this as the electrical spark plug. When the engine starts spinning the rotor, this tiny bit of residual magnetism induces a small current in the exciter windings. This small current is then amplified by the Automatic Voltage Regulator (AVR) and fed back to the rotor windings, creating a powerful electromagnetic field, which is what actually produces the full voltage and amperage. If the generator has sat idle for too long, been exposed to heavy vibration, or experienced a major short circuit, this residual magnetism can be lost. This condition is the single most common answer to the question, “why is my generator not producing power?”

Phase 1: The Easy Checks—Simple Electrical and Safety Faults

Before you dismantle anything or call a technician, check these four simple items. Over 80% of “no power” issues are resolved right here.

1. Tripped Circuit Breakers

Generators have dedicated circuit breakers, distinct from your home’s main panel. These devices protect the generator’s internal wiring from damage caused by an overload (too many appliances running) or a short circuit (a fault in an appliance or cord). If the power suddenly cut out while running, one or more breakers has likely tripped.

- Action: Disconnect all loads from the generator. Locate the breaker switches on the control panel. A tripped breaker will be in the ‘OFF’ or a central, neutral position. Flip the switch fully to the ‘OFF’ position, and then firmly back to the ‘ON’ position.

- Tip: If the breaker trips again immediately after resetting, you have a grounded or shorted appliance/cord still connected, or a more serious internal generator fault.

2. Low Oil and Safety Shutdown

Modern generators, especially smaller portable home backup generators (like those reviewed here), feature a low oil pressure sensor or switch. This safety mechanism instantly shuts down the engine or prevents electrical output if the oil level is too low. Sometimes, if the engine is running, a sensor fault or extremely low oil pressure can stop power generation as a pre-emptive measure.

- Action: Check the oil level immediately. Add oil until it reaches the correct fill mark on the dipstick. Ensure the generator is on a perfectly level surface; even a slight tilt can trick the sensor.

3. Loss of Residual Magnetism (Flashing the Field)

If the engine is running smoothly but there is absolutely no voltage output, you must restore the residual magnetism. This procedure is often called flashing the field.

- Method (For many brushed generators): This typically involves using a 12-volt car battery and briefly applying DC current to the exciter windings to “re-magnetize” the rotor. This is a technical procedure and the wiring differs by manufacturer (e.g., Generac, Honda, Champion). Crucially, consult your owner’s manual before attempting this. Incorrect polarity or duration can fry the Automatic Voltage Regulator (AVR).

- Safer Alternative: On some small generators, running the unit at full speed and briefly plugging in a large, purely resistive load (like a heavy-duty electric heater or a halogen lamp, not a motor or sensitive electronics) can sometimes shock the exciter circuit back to life.

4. Faulty Power Cords or Receptacles

Check your connections. Are you using the correct gauge extension cord for the load and distance? Long runs of thin wire lead to severe voltage drop, which can look like a generator failure. Furthermore, test all outlets on the generator. If power comes out of one receptacle (like the 120V) but not the other (like the 240V twist-lock), the fault is localized to that specific outlet or its internal connection.

Phase 2: Deep Dive into the Alternator Components

If the easy checks fail, the problem is most likely deep within the alternator head, involving the components responsible for creating and regulating the electrical output.

1. The Automatic Voltage Regulator (AVR) Failure

The AVR is arguably the most vulnerable electronic component in the system. It’s a small, sealed box that controls the flow of power to the exciter windings. It constantly monitors the output voltage and adjusts the excitation current to ensure the voltage remains stable, typically at 120V or 240V. Without the AVR correctly feeding power to the rotor, the alternator cannot sustain the powerful electromagnetic field needed for full output.

- Symptoms: Zero voltage, wildly fluctuating voltage (surging), or voltage consistently too high/low.

- Diagnosis: The AVR is difficult to test reliably without specialized equipment. If you’ve ruled out residual magnetism, the AVR is the top electrical suspect. It often fails due to heat, vibration, or voltage spikes and is usually replaced as a complete unit.

2. Worn or Damaged Carbon Brushes (Brushed Generators)

Generators with brushes use small carbon blocks that physically ride against slip rings to transfer the excitation current from the AVR to the rotor windings. Over hundreds of hours of use, these carbon brushes wear down. When they become too short, or if the springs that push them against the slip rings fail, electrical contact is lost, and the excitation circuit breaks, resulting in no power output.

- Action: Unplug the generator and remove the brush inspection cover (usually on the alternator end-bell). Check the length of the brushes and ensure they move freely. If they are less than 1/2 inch long or are chipped, replace them.

3. Diode Failure (Brushless Generators)

In a brushless generator—common in high-end units and large whole house generators (which you can learn more about here)—the function of transferring current is handled by a set of rotating diodes. These act as one-way electrical gates, converting the induced AC current in the exciter armature into the DC current needed by the main field rotor. If one or more of these diodes fails (burns out), the generator loses its ability to sustain the main magnetic field, leading to little or no output. Testing and replacing diodes is often a job for a qualified electrician.

4. Stator or Rotor Winding Faults

This is the most serious failure. The hundreds of feet of copper wiring (the windings) in the stationary stator or the spinning rotor can be damaged. This damage can be due to overheating (leading to insulation breakdown), moisture, or mechanical vibration. The winding can become:

- Shorted: Current bypasses some coils, reducing output dramatically.

- Open: A complete break in the wire, resulting in zero output.

- Grounded: The winding touches the metal frame, causing a catastrophic short and loss of power.

These faults require measuring the resistance and checking the continuity of the windings with a multimeter. The specific resistance values are unique to each generator model and must be compared to the manufacturer’s specifications—a task requiring technical manuals and expertise.

Phase 3: When the Engine is the Electrical Problem

Even if your engine is running, its performance directly impacts the electrical output, particularly the frequency and the voltage regulation.

1. Incorrect Engine Speed (RPM)

Electricity generation requires precise timing. To produce the standard North American frequency of 60 Hertz (Hz), a 2-pole generator must run at 3600 RPM, and a 4-pole generator at 1800 RPM. If the engine speed is too low (e.g., due to a sluggish carburetor or a fuel issue), both the frequency and the voltage will drop, sometimes falling below the level needed to properly excite the AVR, resulting in no usable power. Similarly, an engine that surges (runs too fast, then too slow) indicates a governor issue that directly impacts voltage stability.

For more technical detail on how this speed translates to stable output, you can review information on what is voltage regulation.

2. Governor Malfunction

The governor is the mechanism that automatically adjusts the engine’s throttle to maintain constant RPM regardless of the load demand. If the engine is running but not producing power due to low speed, the governor linkage might be sticky, broken, or improperly adjusted. The governor is critical for maintaining stable voltage output.

- Action: Visually inspect the linkage between the governor arm and the carburetor throttle. Ensure all parts move freely. If the engine speed doesn’t increase when a load is applied, the governor needs repair or adjustment.

Phase 4: Advanced Troubleshooting and Digital Systems

Newer generators, particularly inverter generators and large standby units, feature complex digital controls that introduce new potential failure points.

1. Inverter Board Failure

Inverter generators produce AC power, convert it to DC, and then invert it back to clean AC power at a stable frequency and voltage. The highly sensitive inverter board is the heart of this system. It can fail due to power surges, overheating, or simply component wear. When it fails, the generator’s engine can run perfectly, but the output board will generate little to no power, or only power that is distorted and unusable.

2. Faulty Control Panel or Transfer Switch

For a whole house generator, the problem might not be the generator itself but the communication with the Automatic Transfer Switch (ATS). The ATS might not be receiving the ‘ready’ signal from the generator, or a communication line could be cut. Furthermore, some large generators have a complex digital control panel. If this panel fails, it may prevent the unit from initiating the excitation process even if the components are sound.

Phase 5: Prevention is the Best Power Plan

The best way to address, “why is my generator not producing power?” is to prevent the issue entirely. Most electrical failures stem from neglect.

- Regular Exercise: Run your generator at least once a month for 20-30 minutes under a load (like a few lights or a small heater). This keeps the engine lubricated, circulates the fuel, and—most importantly—recharges the residual magnetism in the alternator.

- Fuel Management: Use a fuel stabilizer when storing gasoline for more than two months. Stale fuel is the number one cause of carburetor problems and subsequent low RPM failures.

- Keep it Clean and Dry: Moisture is corrosive to copper windings and leads to short circuits. Store the generator in a dry location and ensure the air vents are clean and unobstructed to prevent overheating.

- Use Correct Load: Avoid running the generator near its maximum capacity for extended periods. This heat stress accelerates the breakdown of the AVR and winding insulation.

Final Thoughts

Diagnosing why is my generator not producing power can feel overwhelming, but by following a step-by-step diagnostic process, you can narrow down the cause quickly. Always start with the basics: breakers, oil, and the crucial step of restoring residual magnetism. If you’ve exhausted the simpler fixes and the issue appears to involve the AVR, diodes, or internal windings, the cost and complexity warrant calling a certified generator technician. Remember, a generator is a complex machine blending mechanical and electrical engineering. Respect its power, prioritize safety, and with consistent maintenance, you can ensure it delivers reliable power the next time you need it most.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!