For centuries, the art of welding has relied on a delicate balance of skill, precision, and, most importantly, safety. The brilliant, searing arc created during the welding process is a source of intense light and dangerous radiation, including ultraviolet (UV) and infrared (IR) rays. For years, welders protected themselves with passive, fixed-shade helmets, which were effective but came with a significant drawback: they made it impossible to see the workpiece before the arc was struck. This required a constant, tiring ritual of “nodding” the helmet down right before striking the arc. However, a revolutionary piece of technology changed the game forever. The advent of the auto darkening welding helmet marked a new era of efficiency and unparalleled safety for welders everywhere. But have you ever stopped to wonder, how do auto darkening welding helmets work?

This comprehensive guide will demystify the incredible technology behind these modern marvels. We will dive deep into the components, the science, and the practical applications that have made this helmet an essential tool for every serious welder, from the seasoned professional to the eager novice. By understanding the inner workings, you’ll gain a deeper appreciation for the protection it provides and learn how to choose and use the best helmet for your needs.

The Evolution of Welding Safety: From Fixed to Flexible

To truly appreciate the genius of the auto darkening welding helmet, it’s helpful to look at its predecessor: the traditional passive welding helmet. These helmets, which are still in use today, feature a simple, fixed-shade lens, typically a shade 10 or 12. While robust and reliable, their primary function is to block the intense light of the arc, which they do perfectly. However, the fixed dark shade means the welder cannot see anything when the helmet is down and the arc is not struck. Consequently, the welder must lift the helmet to position the electrode and then, with a sharp nod, flip it down just before creating the arc. This constant motion is not only inefficient but can also lead to neck strain over time. Furthermore, a missed nod or a delay in dropping the helmet can expose the eyes to a flash of light, causing what is commonly known as “welder’s flash” or “arc eye,” a painful and temporary condition akin to a sunburn on the cornea. The need for a safer, more convenient solution was evident, and it was this need that spurred the development of the active-darkening lens.

What Exactly is an Auto-Darkening Welding Helmet?

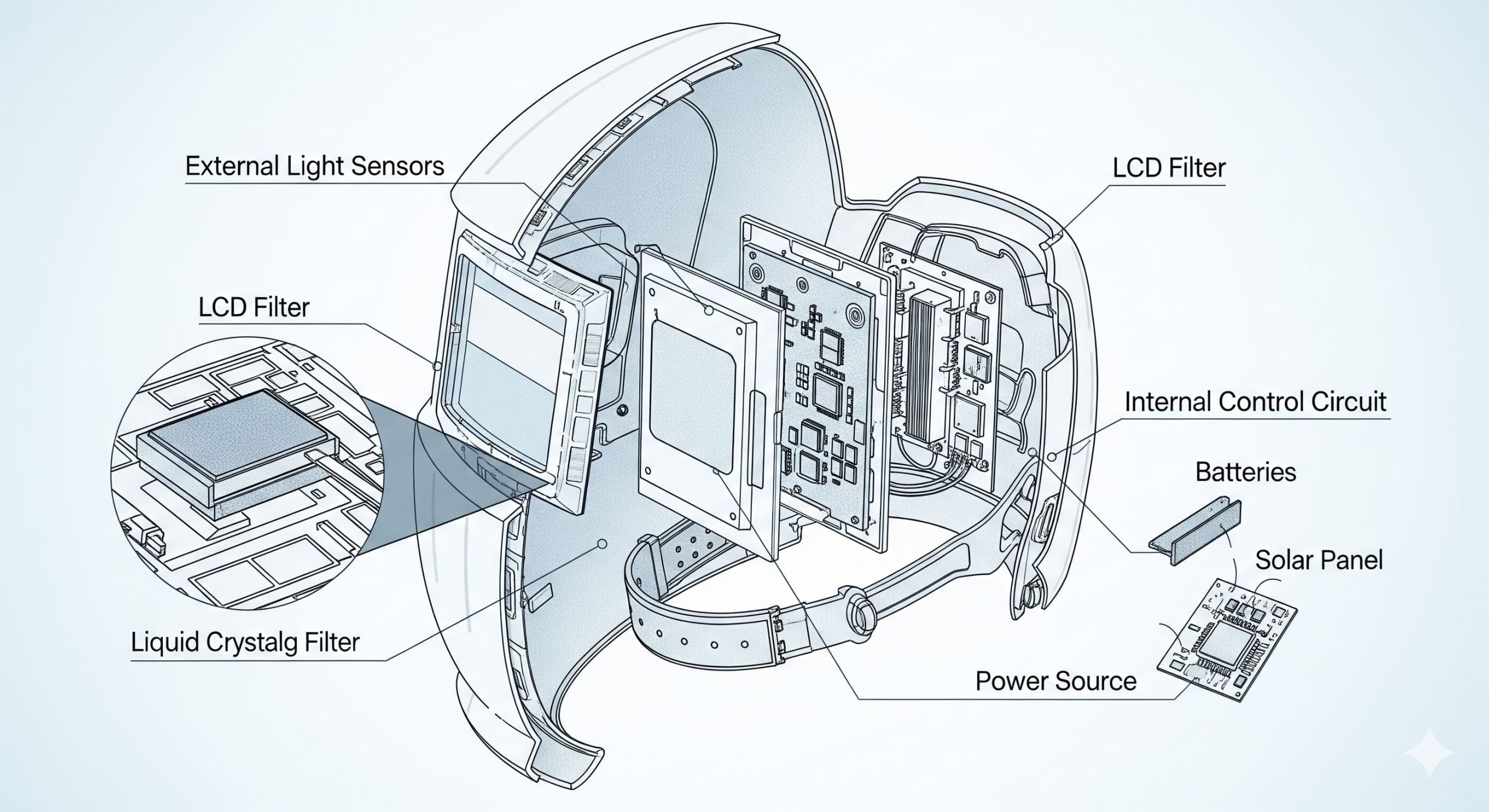

At its core, an auto-darkening welding helmet is a sophisticated piece of personal protective equipment (PPE) designed to protect a welder’s eyes and face from the intense light, heat, and spatter produced during welding. The defining feature, however, is the special liquid crystal display (LCD) filter that makes up the lens. Unlike a fixed-shade lens, this LCD filter remains in a light state (typically a shade 3 or 4) when not in use, allowing the welder to see their workpiece clearly and precisely. The magic happens the instant a welding arc is struck. Within a fraction of a millisecond, the sensors on the helmet detect the sudden change in brightness, and the LCD screen instantly switches to a pre-selected dark state (shades 9 to 13), providing full protection. When the arc is broken, the lens reverts to its light state after a pre-set delay, allowing the welder to inspect the weld bead without having to lift the helmet.

This seamless, automated process not only significantly reduces the risk of eye damage from unexpected flashes but also dramatically improves productivity and comfort for the welder. It allows for more precise starts, reduces neck fatigue, and keeps both hands free for the task at hand, which is especially critical in tight or awkward spaces. The core principle lies in the harmonious interplay of several key components that work together to achieve this almost instantaneous reaction.

The Science Behind the Magic: How They Work

The seemingly simple action of an auto darkening welding helmet is in fact a marvel of modern electronics and chemistry. The process can be broken down into a series of interconnected steps that occur faster than the blink of an eye. Understanding this chain reaction is key to answering the question: how do auto darkening welding helmets work?

The Arc of Light: From Bright to Dark in a Flash

The journey from light to dark begins with the sensors. Located on the front of the helmet, these photo-sensors are highly sensitive to the change in ambient light. When the welding arc is struck, it emits a powerful burst of light, including UV and IR radiation. The sensors immediately detect this change and send a signal to the helmet’s electronic circuitry. This is the first and most critical step. The speed at which this happens is the helmet’s reaction time, a key metric we’ll discuss later. Modern helmets can react as fast as 1/30,000 of a second or even quicker, which is well within the time required to prevent any eye damage from the initial flash.

Once the signal is received, the circuitry, which acts as the brain of the helmet, sends a voltage to the liquid crystal display (LCD) filter. This LCD filter is the heart of the entire operation. It is made of multiple layers, including a liquid crystal layer sandwiched between two polarizing filters. When no voltage is applied, the liquid crystals are in a twisted, disorganized state, and light can pass through the filters, resulting in a clear view. However, when the voltage is applied, the liquid crystals align in a uniform pattern. This alignment prevents light from passing through the polarizing filters, effectively blocking the light and causing the lens to go dark. The amount of voltage applied can also be controlled, allowing for different shade levels.

Finally, when the welding arc is broken, the sensors no longer detect the intense light, and the circuitry cuts the voltage to the LCD. The liquid crystals return to their relaxed, untwisted state, and the lens becomes clear again. This return to the light state is also controlled by a variable delay setting, which prevents the lens from flashing on and off if the arc is briefly interrupted, which is common in certain welding processes like TIG welding. In essence, the entire process is a feedback loop: light is detected, a signal is sent, the voltage is applied, the lens darkens, the light is gone, the voltage is cut, and the lens clears. It’s a beautifully synchronized process that provides a continuous shield for the welder’s eyes.

Key Components and Their Functions

To fully grasp how auto darkening welding helmets work, it’s important to understand the specific roles of each component. Each part is meticulously designed to contribute to the helmet’s overall performance and reliability.

The Sensors

As the “eyes” of the helmet, the sensors are arguably the most crucial component. Most helmets have at least two sensors, but professional-grade models often have four. The more sensors a helmet has, the more reliable its performance, especially in obstructed or out-of-position welding. If one or two sensors are blocked by the welder’s hand or an obstruction, the others can still detect the arc, ensuring the lens darkens. The placement of these sensors is also strategic, designed to cover a wide field of view and detect the arc no matter the angle.

The Liquid Crystal Display (LCD) Screen

This is the actual darkening lens. It’s a complex, multi-layered piece of technology. Besides the liquid crystal layer and polarizing filters, it also contains layers that provide permanent protection from harmful UV and IR radiation. Even in its light state, a good quality LCD screen offers full UV/IR protection, which is a critical safety feature. This means that even if the helmet’s electronics fail or the batteries die, your eyes are still shielded from these invisible, but highly dangerous, forms of radiation. The quality of the LCD is measured by its optical clarity, a key feature that affects how well you can see through the lens.

The Power Source

Most auto darkening welding helmets are powered by a combination of batteries and a solar cell. The solar cell uses the energy from the welding arc itself to trickle-charge the batteries, significantly extending their life. Some helmets rely solely on replaceable batteries, while others have a non-replaceable, solar-charged battery. The combination of solar power and traditional batteries is an efficient system that ensures the helmet is always ready to go. The power source is vital to the quick and reliable operation of the helmet, as the sensors and circuitry require a constant supply of energy to function correctly.

The Control Circuitry

This is the “brain” of the helmet. It receives signals from the sensors, processes them, and sends a precise voltage to the LCD filter. The circuitry also manages the various settings on the helmet, such as the shade level, sensitivity, and delay. The sensitivity setting determines how bright the light has to be to trigger the darkening. The delay setting controls how long the lens stays dark after the arc is extinguished. These customizable controls are what make a modern helmet so versatile and adaptable to different welding processes and environments.

Understanding the Variables: Key Features to Look For

When shopping for a helmet, understanding these key features is crucial. They go beyond the basic question of how do auto darkening welding helmets work? and help you find a helmet that performs optimally for your specific needs.

Shade Levels and Adjustability

The shade level refers to the darkness of the lens when it is in the active, dark state. Most helmets have a variable shade range, typically from shade 9 to 13. This allows the welder to adjust the darkness to match the specific amperage and welding process they are using. For example, high-amperage TIG welding requires a darker shade than low-amperage MIG welding. Additionally, many helmets have a “Grind Mode,” which locks the lens in its light state (shade 3-4), making it safe and easy to grind metal without having to remove the helmet. This is a significant convenience and safety feature.

Reaction Time

As mentioned earlier, reaction time is the speed at which the lens switches from its light to dark state. It’s measured in fractions of a second. The faster the reaction time, the less exposure your eyes have to the initial flash of light. A reaction time of 1/25,000 of a second or faster is considered excellent and provides superior protection against arc flash.

Optical Clarity (Clarity Rating)

The optical clarity of a welding helmet lens is rated on a scale of 1 to 3 for four different parameters: Optical Class, Diffusion of Light Class, Variations in Luminous Transmittance Class, and Angle Dependency of Luminous Transmittance Class. A rating of 1/1/1/1 is the best possible score, indicating the clearest and most distortion-free view. A high clarity rating reduces eye strain and allows the welder to see the weld puddle and surrounding area with exceptional detail and accuracy, which is vital for producing high-quality welds.

Viewing Area Size

The size of the viewing area is a matter of personal preference, but generally, a larger viewing area provides a wider field of vision and greater comfort for the welder. A larger lens allows the welder to see more of their work area without having to constantly reposition their head. Different sizes are available, from standard to extra-large, and this feature can significantly impact a welder’s comfort and efficiency, especially during long welding sessions.

Number of Sensors

While two sensors are the minimum for most helmets, four sensors offer superior performance. The additional sensors provide better coverage and reduce the risk of the lens failing to darken in out-of-position or obstructed welding situations. For professionals who frequently work in challenging conditions, a four-sensor helmet is a worthwhile investment. This increased reliability is a key differentiator between entry-level and professional-grade helmets.

From the Shop Floor: Practical Usage and Best Practices

Knowing how do auto darkening welding helmets work is just the first step. Proper usage and maintenance are equally important to ensure the helmet provides maximum protection and longevity. Here are some practical tips to get the most out of your helmet.

Calibrating Your Helmet for Different Tasks

Before you start welding, it’s essential to set your helmet’s sensitivity and delay correctly. The sensitivity should be set based on the ambient light and the welding process. For low-amp TIG welding, you’ll need a higher sensitivity to ensure the helmet darkens quickly. For bright, outdoor work, a lower sensitivity might be needed to prevent false triggering from sunlight. The delay setting should be adjusted based on the welding process. A shorter delay is fine for stick or MIG welding, but a longer delay is crucial for TIG welding to prevent the lens from flickering on and off between quick tack welds.

Maintaining Your Investment

An auto darkening welding helmet is a precision instrument, and like any other tool, it requires regular care. The most important maintenance step is keeping the lens clean. Dust, spatter, and grime can affect the sensors’ ability to detect the arc and can scratch the outer lens. It’s important to clean the lens with a soft cloth and a mild cleaner designed for plastics. Never use harsh solvents or abrasive materials. Replacing the outer and inner protective lenses when they become scratched or pitted is also essential to maintain a clear view and prolong the life of the more expensive auto-darkening cartridge. For detailed instructions on this process, you can find a guide here: how to clean welding helmet lens.

Beyond the Basics: Advanced Features and Future Technology

The evolution of the auto darkening welding helmet isn’t stopping. Manufacturers are constantly innovating to improve safety, comfort, and performance. One of the most significant recent advancements is “True Color” technology. Older lenses had a green or amber tint, which distorted the colors of the weld puddle and the surrounding area. True Color technology uses advanced optics to provide a much more natural and realistic view, making it easier to see the details of the weld pool and improving weld quality. Some advanced helmets also feature integrated LED task lights, which are incredibly useful for working in poorly lit areas. For a look at some of the top models with these features, you can check out this list of the best auto darkening welding helmets.

The future of this technology points towards even greater connectivity and intelligence. We may see helmets with integrated heads-up displays (HUDs) that provide real-time data about the welding process, or helmets that communicate with welding machines to automatically adjust settings. The possibilities are truly exciting, all building on the fundamental technology of the modern auto-darkening lens. For more technical information on the components and history, you can also refer to the Wikipedia page on welding helmets.

Comparing Auto-Darkening vs. Traditional Passive Helmets

While the focus of this article is on the modern auto-darkening helmet, it’s worth a quick comparison to its passive counterpart. The decision of which to use often comes down to personal preference and budget, but the advantages of the auto-darkening helmet are clear.

- Safety: Auto-darkening helmets provide instantaneous protection, greatly reducing the risk of arc flash and its associated pain and discomfort.

- Efficiency: The ability to see before and after the arc is struck means no more “head nodding,” leading to faster, more precise starts and overall increased productivity.

- Comfort: The ergonomic benefits of not constantly moving the helmet up and down can prevent neck and back strain over a career.

Of course, passive helmets are still a valid choice for their simplicity, low cost, and durability (with no electronics to fail). However, for the majority of welders today, the benefits of the modern auto darkening welding helmet far outweigh the initial investment, making it the clear choice for anyone serious about their safety and craft. A detailed comparison of the different types of helmets can be found in this article on types of welding helmets.

Final Thoughts

In conclusion, the answer to the question, how do auto darkening welding helmets work? is a fascinating blend of light-sensing technology, liquid crystal chemistry, and sophisticated electronics. This seamless process has not only revolutionized welding safety but has also dramatically improved the efficiency and comfort of welders worldwide. By understanding the core components—the sensors, the LCD, the power source, and the control circuitry—you can appreciate the science that keeps your eyes safe from a dazzling, yet dangerous, arc of light.

This technology is more than just a convenience; it is a vital tool that protects a welder’s most valuable asset—their sight. As welding techniques and technologies continue to evolve, the auto darkening welding helmet will undoubtedly remain at the forefront of innovation, ensuring that the ancient art of joining metal continues to be a safe and rewarding profession for generations to come. Therefore, whether you’re a hobbyist or a professional, investing in a high-quality auto-darkening helmet is one of the best decisions you can make for your safety and success in the world of welding.

Amranul is a highly experienced product review writer with a passion for helping readers make smart, informed purchasing decisions. Since 2018, he has specialized in thoroughly researching and analyzing a wide range of products to deliver honest, in-depth reviews. Amranul combines technical accuracy with clear, engaging writing to break down complex product features and highlight true user value. Look for his reviews to find reliable information and expert insights you can trust before you buy!